Automatic PPR pipe fusion-welding robot and fusion-welding method

A robot and welding technology, which is applied in the field of automatic PPR pipe welding robot, can solve the problems of potential safety hazards, missing the best time and best state of pipe welding, and failure to reach it, so as to reduce waste, facilitate promotion and use, and greatly upgrade effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

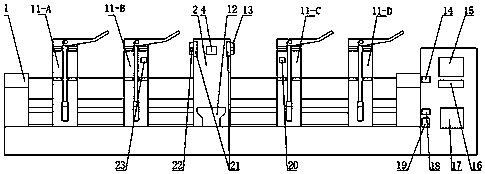

[0013] Specific implementation mode one: see figure 1 To illustrate this embodiment, the automatic PPR pipe welding robot and welding method include a base 1, a die clamping unit 2 is arranged in the middle above the base 1, and two sides of the die clamping unit 2 are provided with Die heads 13 of different types can be used. The die head 13 is provided with a temperature sensor 22. The back of the die head 13 on both sides is provided with a heating core 21. The heating core 21 is connected to the die head 13. An infrared thermal imaging camera 4 is arranged in the middle of the die clamping unit 2; pipe clamping units 3 are arranged on both sides of the die clamping unit 2, and four sets of clamps 11-A, 11-B, 11-C, 11-D, the fixtures 11-B, 11-C are respectively provided with a laser transmitter 20 and a laser receiver 23; the right side of the base 1 is provided with a single-chip motherboard 17, so The top of the single-chip microcomputer mainboard 17 is provided with a b...

specific Embodiment approach 2

[0014] Specific implementation method two: please refer to figure 1 Describe this embodiment, the automatic PPR pipe robot and welding method, the die head clamping unit 2 slides along the die head guide rail 12 .

specific Embodiment approach 3

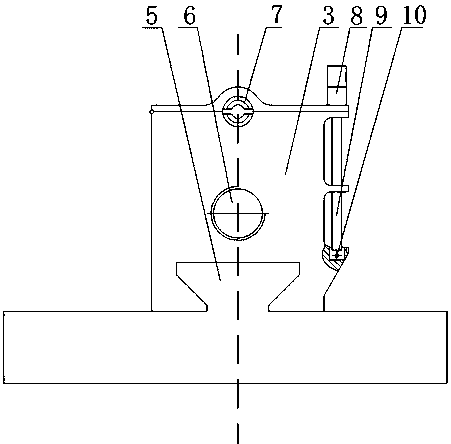

[0015] Specific implementation method three: please refer to figure 2 Describe the present embodiment, the automatic PPR pipe robot and welding method, the pipe clamping unit is provided with 6 lead screws, clamps 11 and clamp guide rails 5; the lead screw 6 and the stepper motor 14 are in phase connection; the clamp 11 is provided with positive and negative threads to spirally connect with the lead screw 6 and move along the clamp guide rail 5; the inside of the clamp is provided with a rubber washer 7, and the clamp 11 is provided with a wrench 8, so The wrench 8 adopts a cam structure to make the connection tighter; a screw 9 is arranged under the wrench 8, and the screw 9 and the clamp are connected by a pin 10 to fine-tune the tightness of the mechanism, so the pipe clamping unit 3 can be used To clamp pipes of different specifications, and under the control of the single-chip microcomputer 17, automatic docking can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com