Tail rope suspension device of skip bucket and method for replacing tail rope

A suspension device, tail rope technology, applied in transportation and packaging, lifting equipment in mines, etc., can solve the problems of high labor intensity, long operation time and low work efficiency, and achieve high labor intensity, long operation time and low work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

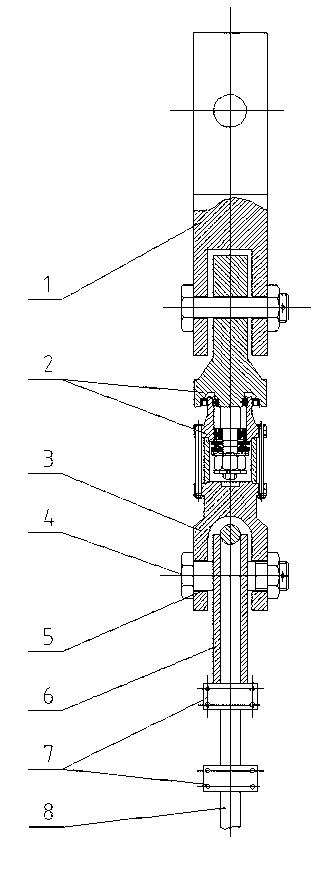

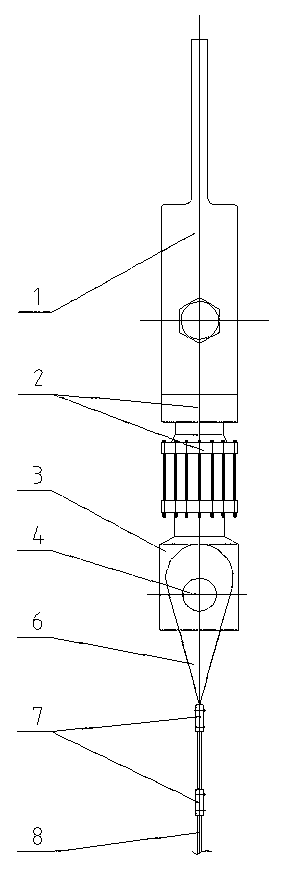

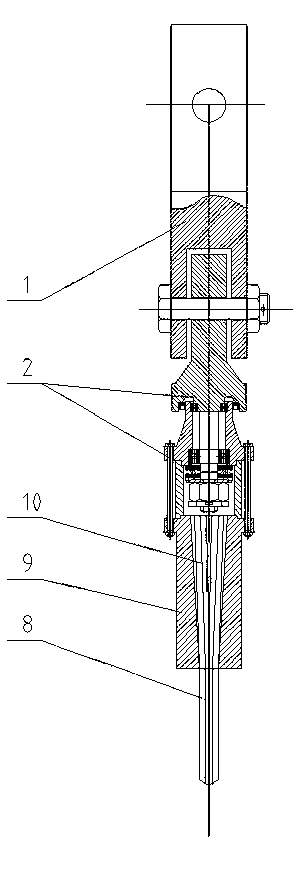

[0011] Example 1 Such as figure 1 , 2 Shown: a skip tail rope suspension device, including a sling 1, a rotating mechanism 2 and a steel wire tail rope 8, the rotating mechanism 2 and the suspension ring 3 are connected by longitudinal bolts, and the suspension ring 3 with a transverse round hole 5 is connected to a peach-shaped The ring 6 is connected by a transverse bolt 4; one end of the steel wire tail rope 8 passes through and surrounds the groove of the peach-shaped ring 6, and is fastened to the steel wire tail rope 8 by two rope clips 7 under the peach-shaped ring 6.

Embodiment 2

[0012] Example 2 Such as figure 1 , 2 shown : Adopt the method for renewing the tail rope of a skip tail rope suspension device described in Embodiment 1; when changing the rope, first loosen the rope clamp 7, remove the waste steel wire tail rope, and then pass one end of the new steel wire tail rope 8 through and around the peach The groove of the annular ring 6 is under the peach-shaped annular ring 6, and the new steel wire tail rope 8 is clamped by the rope clamp 7; it is convenient and fast, with low labor intensity, short replacement time, high efficiency and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com