Asphalt pavement hot in-place recycling process and system

An asphalt pavement and geothermal technology, which is applied in the field of asphalt pavement laying, can solve the problems of low thermal conductivity of asphalt, difficulty in heating asphalt concrete pavement, and easy overheating, aging and burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

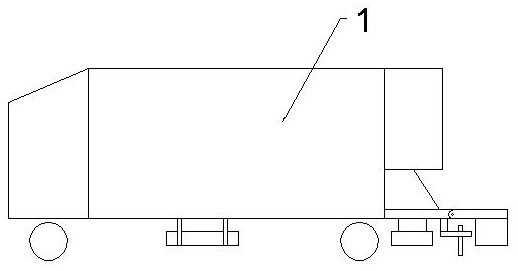

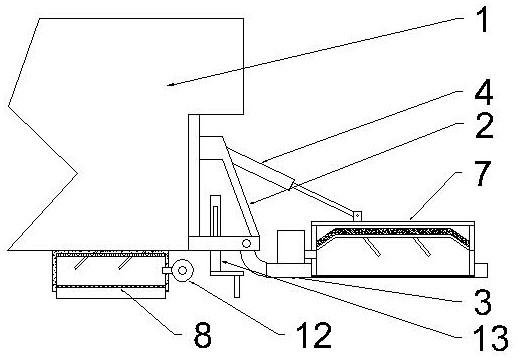

[0021] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Figure 8 , the hot-in-place regeneration process for asphalt pavement described in this embodiment includes the following steps: heating the old road surface - hot raking - reheating the old road surface - hot raking or hot milling and spraying additives - adding new asphalt mixture - forming Mixing material belt - material belt reheating - lifting forced remixing - paving recycled mixture - rolling forming;

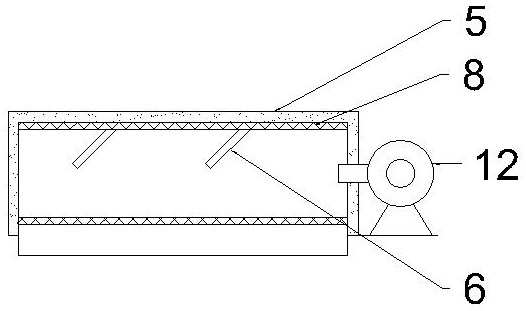

[0022] Hot raking is to carry out hot raking immediately after heating, and then use hot air heating equipment to continue to heat the raked road surface with hot air. Hot raking is to rake and heat through the raking heating system on the heating vehicle.

[0023] The harrowing heating system includes a car body 1, front heating components are installed on both sides of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com