Manual operation vehicle-mounted iron ladle uncovering mechanism device

A cover-opening device and manual operation technology, which is applied in the field of manually-operated vehicle-mounted iron ladle cover-opening mechanism, can solve the problems of applying a lot of manpower, the overall quality of the mechanism, and causing accidents, so as to improve safety and reliability, Timely and effective work, the effect of preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

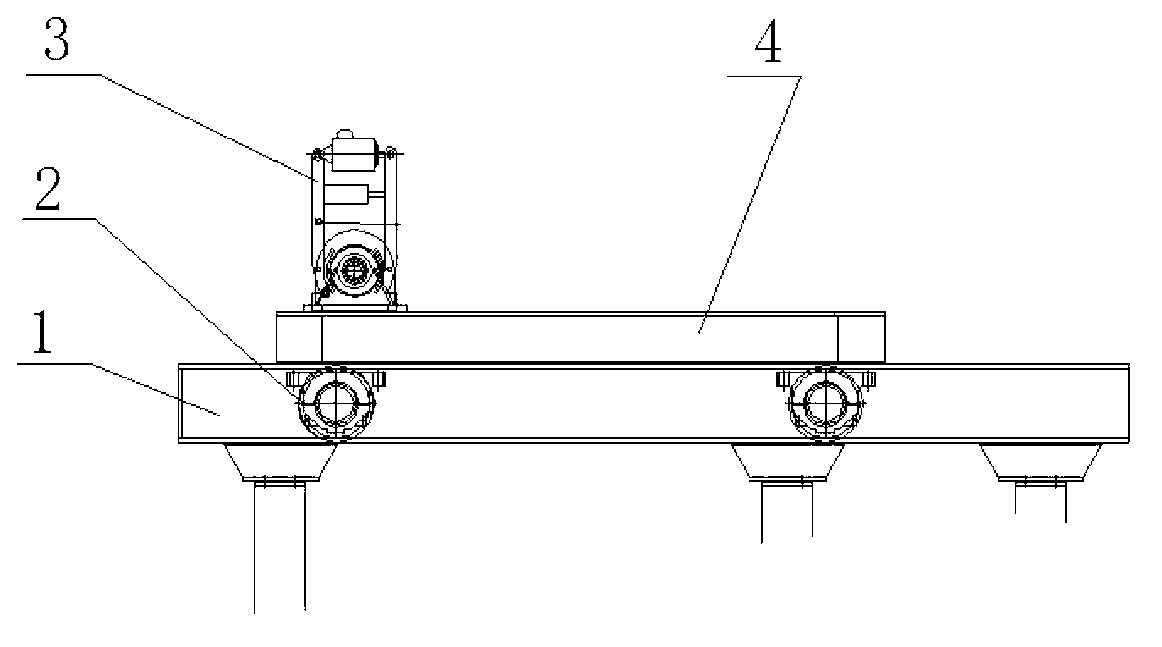

[0018] Such as figure 1 Shown is a schematic structural diagram of the walking mechanism of the present invention: the active wheel set and the passive wheel set 2 are placed at the bottom of the frame 4, and run in the guide rail 1 to drive the entire frame 4 to move horizontally. The driving motor and the motor clutch 3 are installed on the vehicle frame to realize the conversion of the driving force from electric to manual.

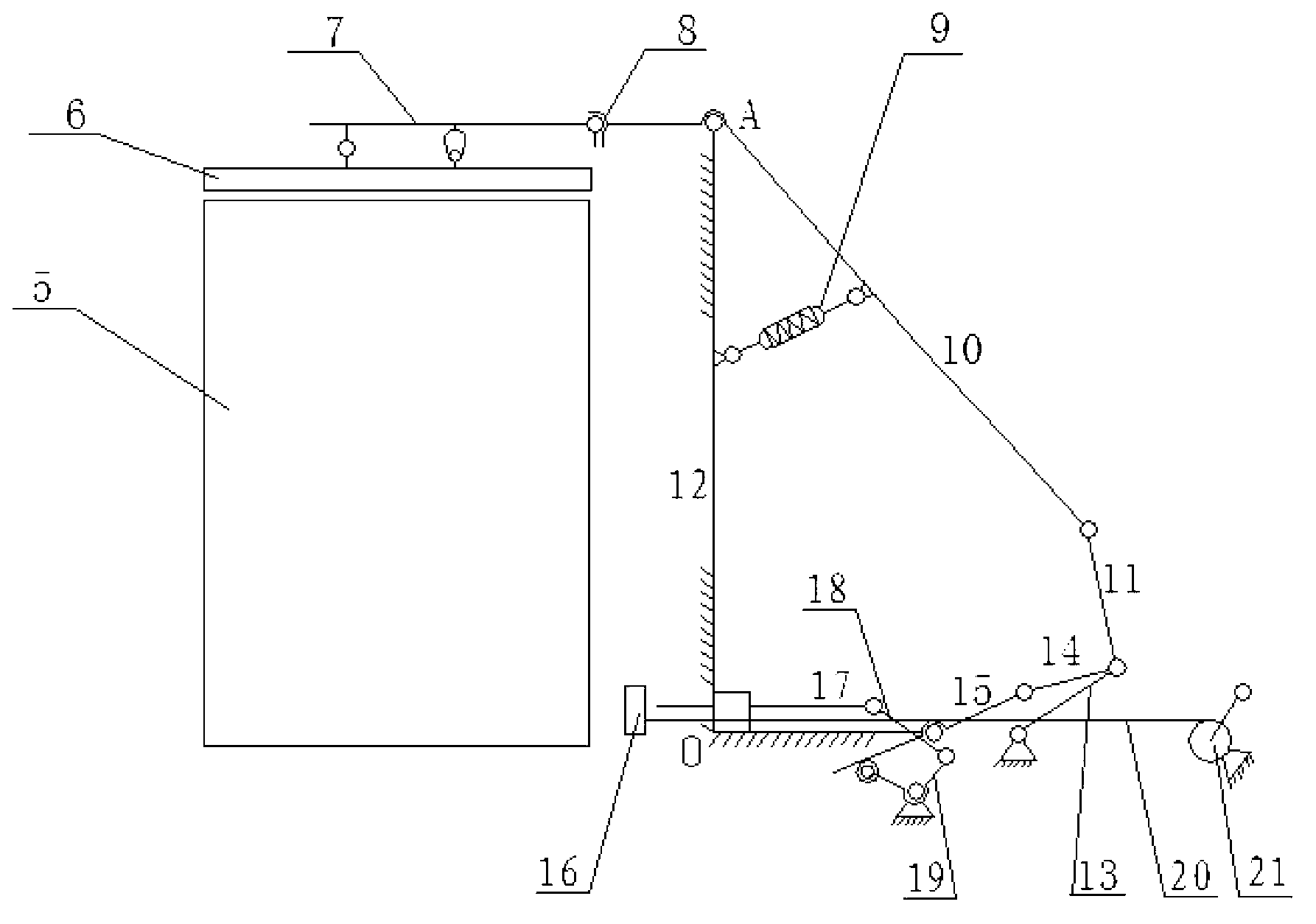

[0019] Such as figure 2 Shown is the traction mechanism of the present invention-the schematic diagram of uncapping mechanism: connecting rod A13, connecting rod B14, connecting rod B15 and frame 12 form the inner ring double rocker four-bar mechanism; opening and closing rocker arm 10, connecting rod A11, The link bar A and the frame form an outer ring double rocker four-bar mechanism; the manual opening and closing push rod 17, the transmission rod 18 and the manual opening and closing ejector rod 19 form a crank slider mechanism. When opening the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com