Europium-erbium co-doped yttrium oxysulfide luminescent material as well as preparation method and application thereof

A technology of yttrium oxysulfide and luminescent materials, applied in the directions of luminescent materials, chemical instruments and methods, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

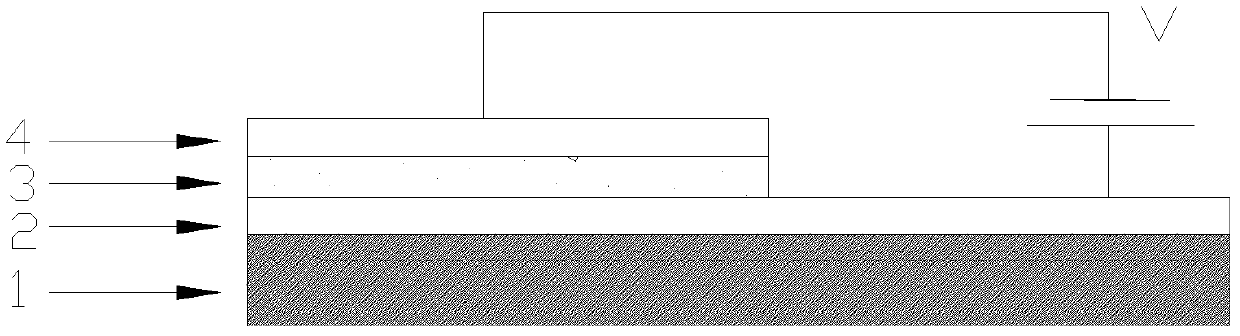

[0036] A method for preparing a thin film electroluminescent display device, comprising the following steps:

[0037] (1) Preparation of luminescent material: take Y with a purity of 99.99% 2 o 3 , sulfur powder, Eu 2 o 3 and Er 2 o 3 Powder, the molar ratio is 1:1.5:0.02:0.03 (ie Y 2 o 2 S:xEu 3+ ,yEr 3+ , x value is 0.02, y value is 0.03) after uniform mixing, sintering at 1250°C to make a luminescent material of Φ50×2mm;

[0038] (2) Prepare the substrate: take the glass substrate with ITO, and use acetone, absolute ethanol and deionized water to carry out ultrasonic cleaning on the glass substrate with ITO in sequence, then perform oxygen plasma treatment, and dry to obtain a clean Substrate;

[0039] (3) Coating: According to the pulse laser deposition method, install the luminescent material and the clean substrate in the vacuum chamber of the pulse laser system, the distance between the luminescent material and the substrate is 60mm, and then use a mechanical ...

Embodiment 2

[0046] A method for preparing a thin film electroluminescent display device, comprising the following steps:

[0047] (1) Preparation of luminescent material: take Y with a purity of 99.99% 2 o 3 , sulfur powder, Eu 2 o 3 and Er 2 o 3 Powder, the molar ratio is 1:1.5:0.01:0.01 (ie Y 2 o 2 S:xEu 3+ ,yEr 3+ , x value is 0.01, y value is 0.01) after uniform mixing, sintering at 900°C to make a luminescent material of Φ50×2mm;

[0048] (2) Preparation of substrate: Take the glass substrate with ITO, and use acetone, absolute ethanol and deionized water to carry out ultrasonic cleaning on the glass substrate with ITO transparent conductive film in sequence, then perform oxygen plasma treatment, dry, and prepare a clean substrate;

[0049] (3) Coating: According to the pulse laser deposition method, install the luminescent material and the clean substrate in the vacuum chamber of the pulse laser system, the distance between the luminescent material and the substrate is 45m...

Embodiment 3

[0053] A method for preparing a thin film electroluminescent display device, comprising the following steps:

[0054] (1) Preparation of luminescent material: take Y with a purity of 99.99% 2 o 3 , sulfur powder, Eu 2 o 3 and Er 2 o 3 Powder, the molar ratio is 1:1.5:0.05:0.06 (ie Y 2 o 2 S:xEu 3+ ,yEr 3+ , x value is 0.05, y value is 0.06) after uniform mixing, sintering at 1300°C to make a luminescent material of Φ50×2mm;

[0055] (2) Prepare the substrate: take the glass substrate with ITO, and use acetone, absolute ethanol and deionized water to carry out ultrasonic cleaning on the glass substrate with ITO transparent conductive film in sequence, then perform oxygen plasma treatment, dry, and prepare a clean substrate;

[0056] (3) Coating: According to the pulse laser deposition method, install the luminescent material and the clean substrate in the vacuum chamber of the pulse laser system, the distance between the luminescent material and the substrate is 95mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com