An automatic dynamic balance structure for axial force of hot water circulating pump

A hot water circulating pump and dynamic balancing technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of bearing operating temperature exceeding, affecting bearing service life, increasing bearing temperature, etc., and improving service life. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

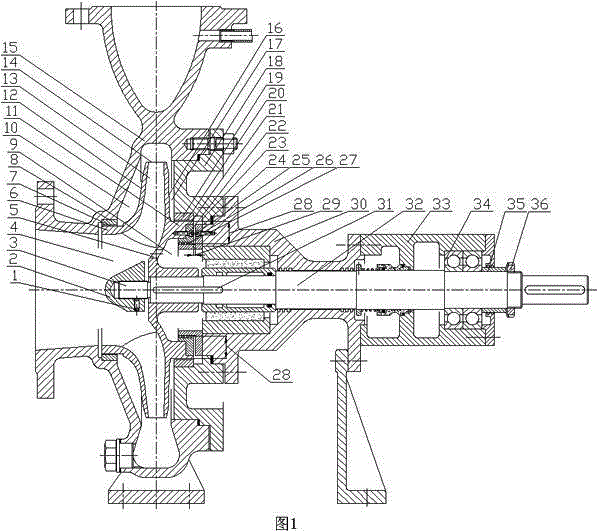

[0015] Combine below figure 1 The specific implementation manner of the present invention will be further described.

[0016] Such as figure 1 As shown, the connection seat 30 is connected with the bearing seat 33, the bearing 34 is installed in the bearing seat 33, the rear pump cover 18 is connected with the connection seat 30, the main shaft 32 is set in the bearing 34 through the connection seat 30, and 35 sets of short shaft sleeves On the main shaft 32, the locking round nut 36 is screwed on the main shaft 32 and supports the bearing 34 through the short shaft sleeve 35, so that the main shaft 32 is axially fixed on the bearing 34, and the balance disc sleeve 24 is fixed on the connecting seat 30 by B screws 26 , The rear sealing ring 19 is installed in the rear pump cover 18, the key 31 is installed on the main shaft 32, the impeller 13 is sleeved on the main shaft 32, and the key 31 is installed between the impeller 13 and the main shaft 32 for circumferential fixing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com