Dust lip for shock absorber

A dust-proof lip and shock absorber technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as friction noise, piston rod interference, oil leakage, etc., to eliminate friction noise and strengthen Sealing performance and the effect of preventing oil leakage from the piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. However, the present invention is not limited or limited to the Examples. The same reference numerals suggest the same parts in the various figures.

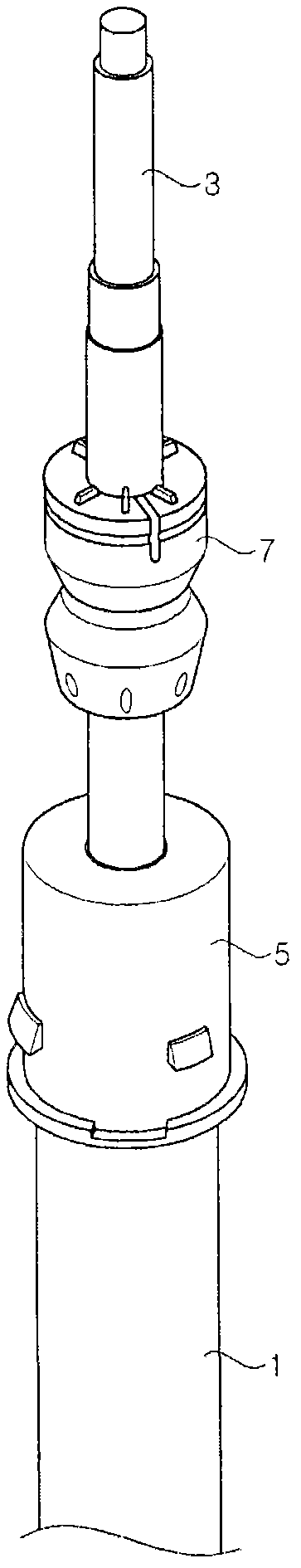

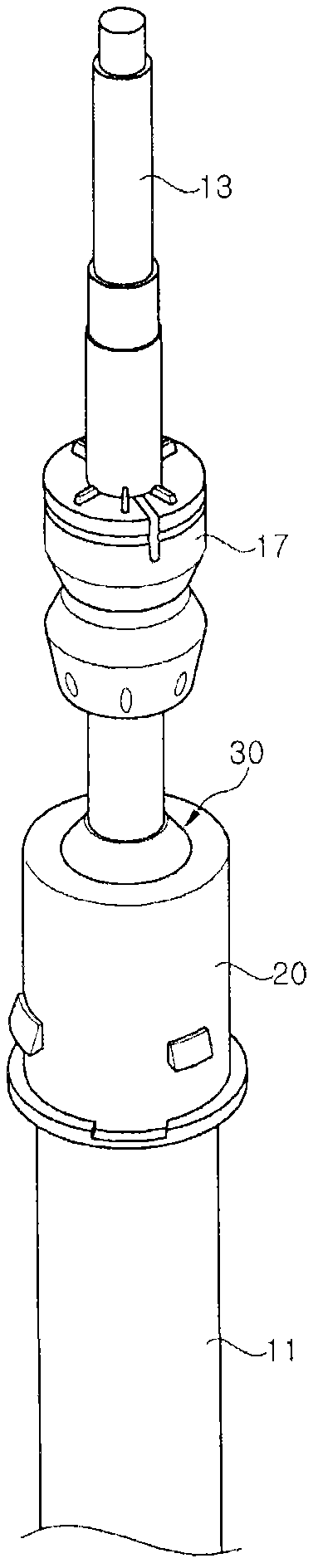

[0028] figure 2 It is a perspective view showing main parts of the shock absorber of the present invention.

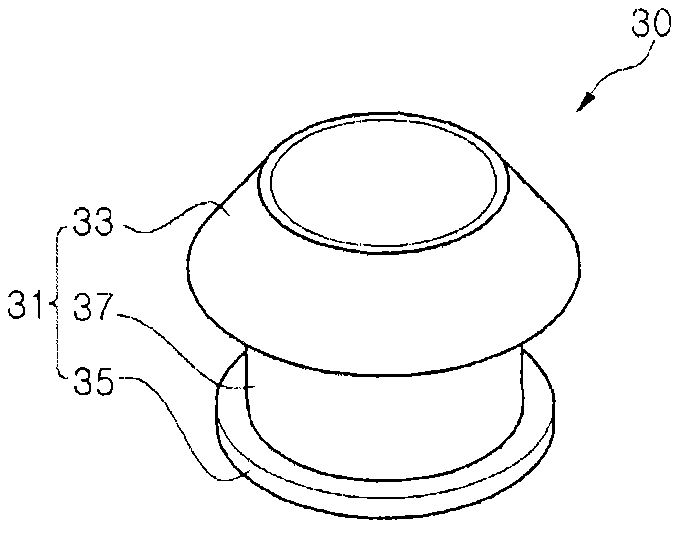

[0029] Such as figure 2 As shown, the cap member 20 of the present invention is attached to the upper end of the base shell 11 . Same as the prior art, a guide rod (not shown) for guiding the linear motion of the piston rod 13 and an oil seal (not shown) for sealing the working oil filled in the cylinder are provided on the upper part of the base shell 11 that constitutes the cylinder shape. out). Further, a buffer rubber 17 is adhered to an outer peripheral surface of the piston rod 13 passing through one end of the base housing 11 and exposed upward. Here, the buffer rubber 17 is normally in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com