Backlight module and display module

A display module and backlight module technology, applied in the direction of optics, electric light source, light source fixation, etc., can solve the problems of destroying the composition of the backlight module, reducing the light utilization rate, reducing the performance of the backlight module, etc., to ensure performance and strength , reduce the thickness, reduce the thickness of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

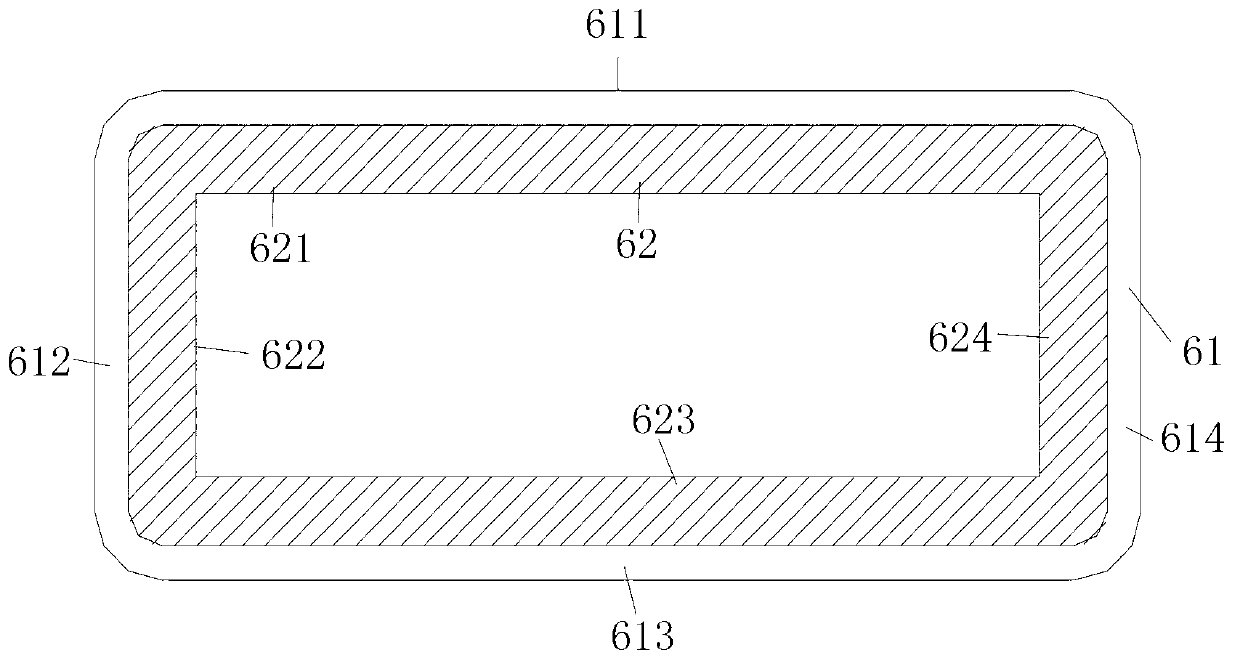

[0038] combined reference Figure 5 to Figure 7 As shown, the technical solution of this embodiment is roughly the same as that of Embodiment 1, and the only difference is that, on the basis of Embodiment 1, this embodiment is provided with a hook 63 on the edge of the bottom edge 62, and The reflector 40 and the plastic frame 70 are provided with corresponding holes 43 and 73, and the hooks 63 are embedded in the holes 43 and 73, thereby strengthening the connection between the bottom edge 62 and the reflector 40 and The connection strength of the plastic frame 70.

[0039] like Image 6 As shown, the bottom 62 is composed of multiple sub-bottoms, at least one hook 63 is provided on the edges of the four sub-bottoms 621, 622, 623 and 624 respectively, and the reflection sheet 40 and the plastic frame 70 are provided with Each of the hooks 63 corresponds to the hole 43 and the hole 73 , so as to enhance the receiving capacity of the reflective sheet 40 . It should be noted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com