Assembly method of heat-exchange device

An assembly method and heat exchange system technology, applied in the field of assembly of heat exchange devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

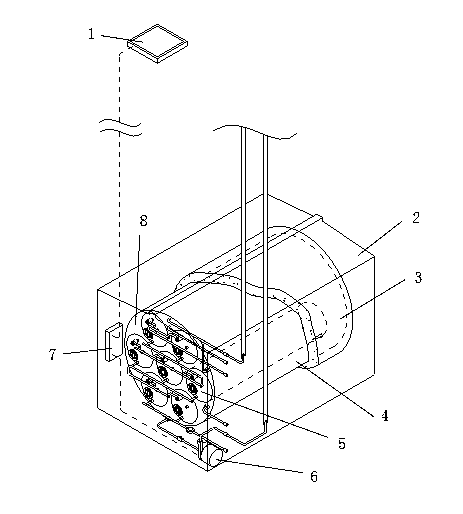

[0026] A. Select the appropriate heat exchange storage tank 5 according to the required hot water storage capacity and exchange capacity (the water tank can be made of SUS 304 / SUS 316 stainless steel or the process of spraying and firing enamel inside the steel body), heat The volume of the exchange hot water storage tank 5 can be between 100L and 500L; the pressure-bearing design requirement of the heat exchange hot water storage tank 5 is above 0.6mpa; Heating rods and other devices.

[0027] B. Combining similar heat exchange storage tanks 5, using a combination of multiple heat exchange storage tanks 5, and then designing the water tank fixing frame 8 for placement according to the water tank specifications and sizes selected above. Use two methods of vertical installation or horizontal installation, and conduct a pressure test of no more than 1.0mpa on the heat exchange hot water storage tank.

[0028] C. Cut the holes equal to the heat exchange storage water tank at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com