Multistage rotary-wheel dehumidification device with auxiliary heat rejection and application method thereof

A rotary dehumidification and rotary wheel technology, applied in heating methods, applications, household heating, etc., can solve problems such as increasing the complexity of the device and affecting the energy efficiency level of the device, achieving efficient operation, flexible design and use, and reducing energy consumption. The effect of matching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

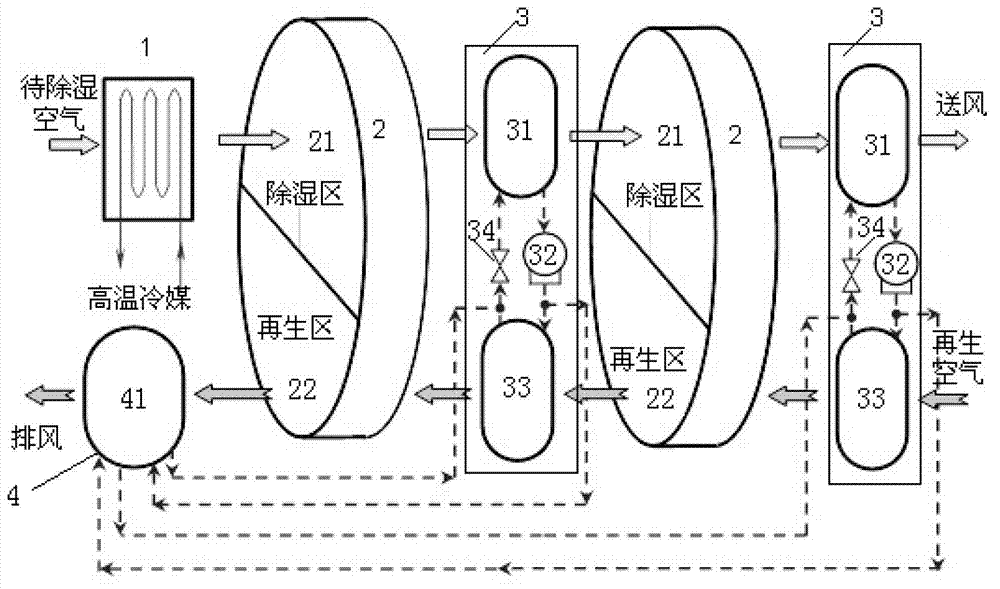

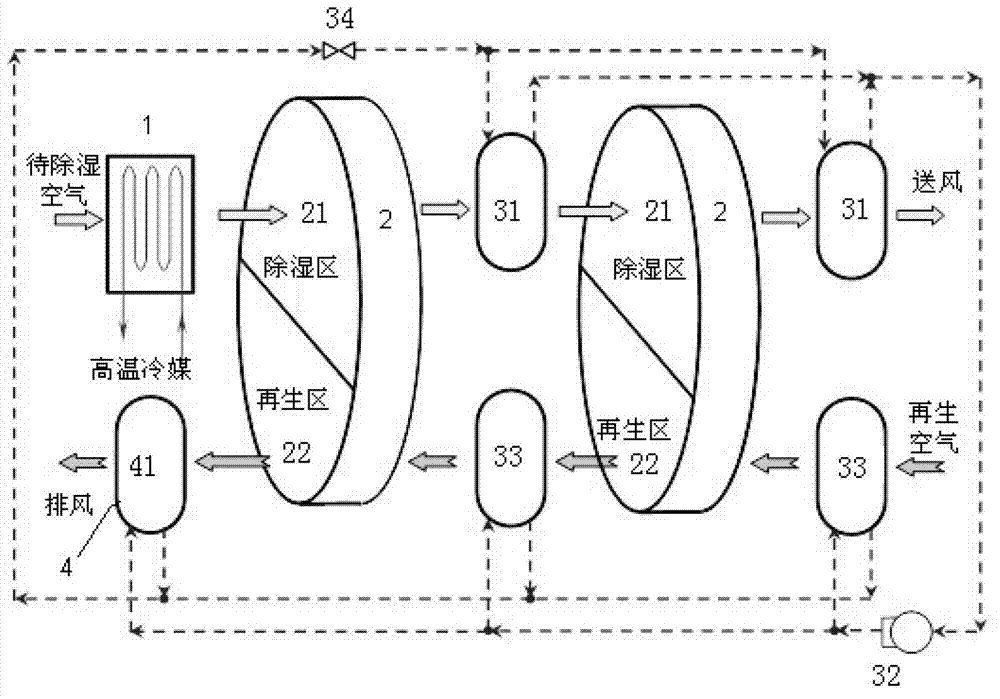

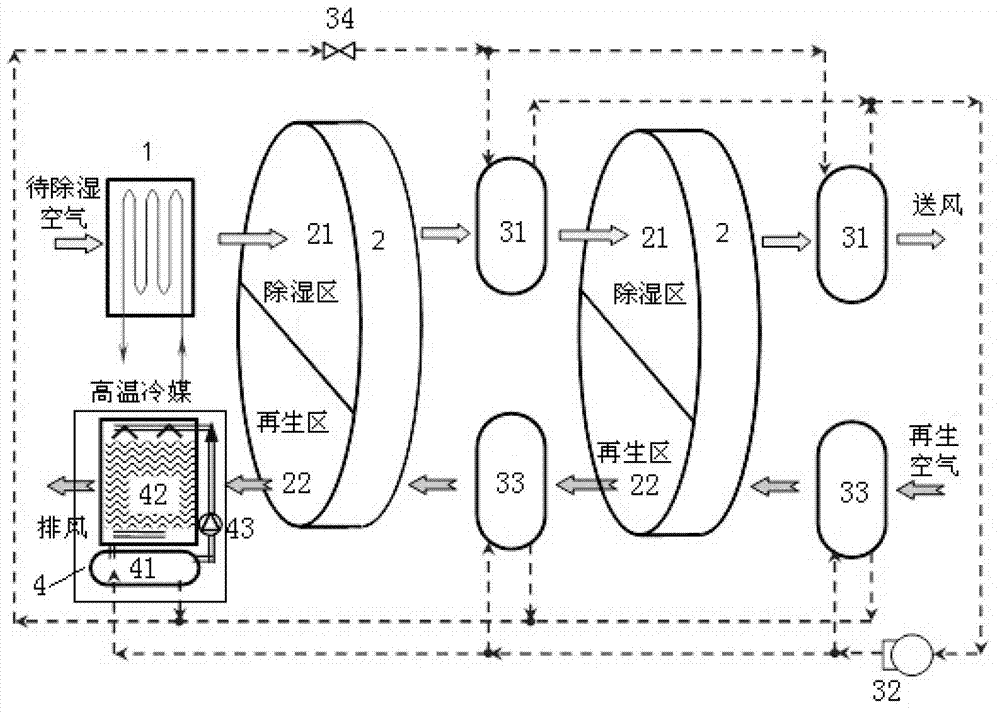

[0018] Such as figure 1 As shown, the device of the present invention includes a pre-cooling treatment unit 1 , a solid moisture absorbent runner 2 , a heat pump circulation unit 3 and an auxiliary cooling device 4 .

[0019] The pre-cooling treatment unit 1 of the present invention is a heat exchanger with heat exchange tubes, and the refrigerant or cold water in the heat exchange tubes is a high-temperature refrigerant for an air-conditioning system with independent temperature and humidity control.

[0020] The solid hygroscopic agent runner 2 of the present invention is a prior art, and it includes two stages arranged at intervals, and each stage of the runner 2 is driven by a driving device to rotate slowly, and the solid hygroscopic agent positioned on the air supply path is used as a dehumidification zone 21, Realize the dehumidification proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com