Device and method for direct liquefaction of pipeline natural gas using expander

A technology of liquefied natural gas and expander, which is applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of high liquefaction rate, unreachable natural gas, complex process structure, etc., and achieve the effect of low cost, less equipment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

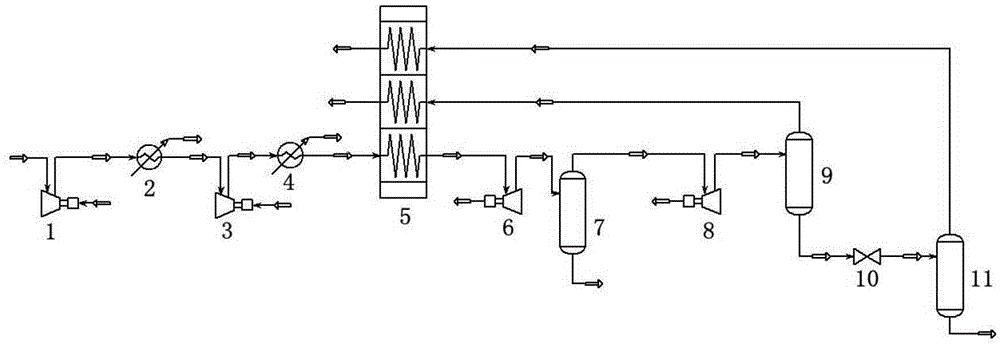

[0039]This embodiment relates to a device for directly liquefying pipeline natural gas by using an expander. The device consists of a first-stage supercharger, a first-stage water cooler, a second-stage supercharger, a second-stage water cooler, and a main heat exchanger , a first-stage expander, a heavy hydrocarbon separator, a second-stage expander, a first-stage gas-liquid separator, a throttle valve and a second-stage gas-liquid separator, and its structure is as follows figure 1 shown.

[0040] This embodiment also relates to a method for preparing liquefied natural gas using the aforementioned device, the method comprising the following steps:

[0041] Step 1, divide the molar composition into 94% CH 4 , 4%C 3 h 8 and 2%N 2 , Natural gas with a pressure of 4.5MPa, a temperature of 35°C and a flow rate of 1kmol / h is boosted to 6.33MPa by a two-stage supercharger, and then cooled to 40°C by a two-stage water cooler;

[0042] Step 2, the natural gas cooled in step 1 en...

Embodiment 2

[0048] This embodiment relates to a device for directly liquefying pipeline natural gas by using an expander. The device consists of a first-stage supercharger, a first-stage water cooler, a second-stage supercharger, a second-stage water cooler, and a main heat exchanger , a first-stage expander, a heavy hydrocarbon separator, a second-stage expander, a first-stage gas-liquid separator, a throttle valve and a second-stage gas-liquid separator, and its structure is as follows figure 1 shown.

[0049] This embodiment also relates to a method for preparing liquefied natural gas using the aforementioned device, the method comprising the following steps:

[0050] Step 1, divide the molar composition into 94% CH 4 , 4%C 3 h 8 and 2%N 2 , Natural gas with a pressure of 5.0MPa, a temperature of 35°C and a flow rate of 1kmol / h is boosted to 7.82MPa by a two-stage supercharger, and then cooled to 40°C by a two-stage water cooler;

[0051] Step 2, the natural gas cooled in step 1 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com