A regenerative mixed refrigerant gas liquefaction cycle system

A technology of mixed working fluid and circulation system, which is applied in the direction of refrigeration and liquefaction, liquefaction, lighting and heating equipment, etc., and can solve problems such as time-consuming and complicated restart process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

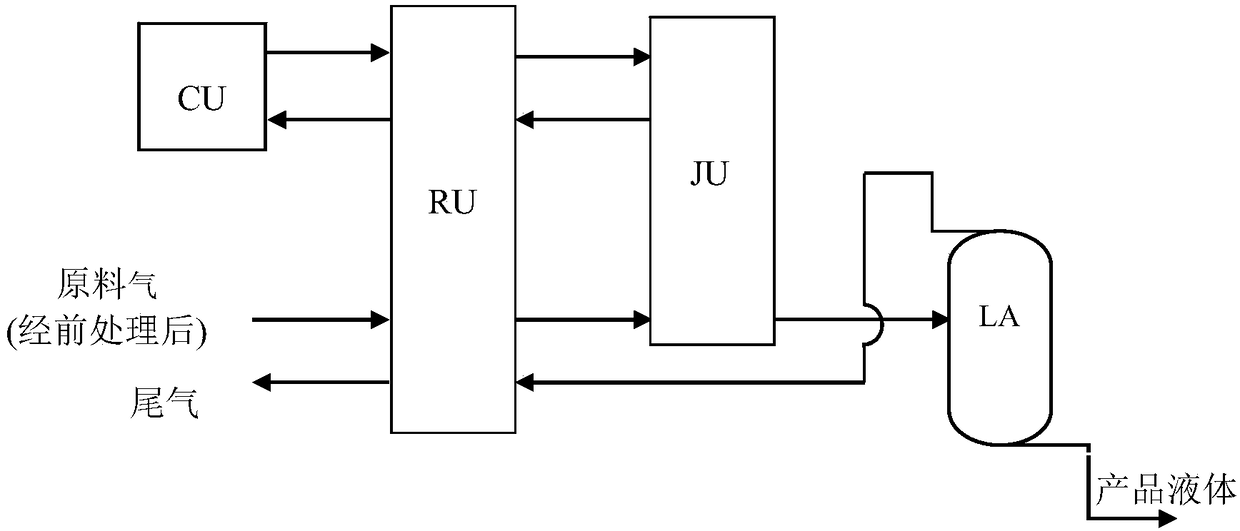

[0049] Example 1: A basic regenerative mixed working medium refrigeration natural gas liquefaction cycle system

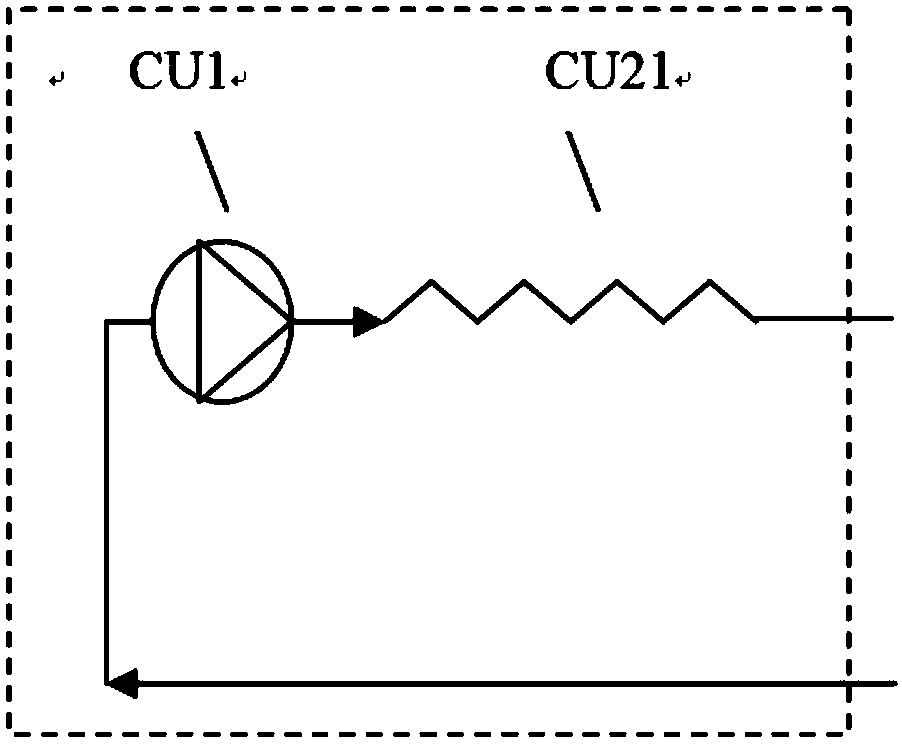

[0050] figure 1 It is a structural schematic diagram of the regenerative mixed refrigerant gas liquefaction cycle system of this embodiment. image 3 It is a structural schematic diagram of a compressor module CU in this embodiment. Figure 4 It is a structural schematic diagram of a regenerative heat exchanger module RU in this embodiment. Figure 5 It is a structural schematic diagram of a throttling module JU of this embodiment.

[0051] The regenerative mixed refrigerant gas liquefaction cycle system provided in this embodiment includes a compressor module CU, a regenerative heat exchanger module RU, a throttling module JU, a liquid storage tank LA, a gas liquefaction circuit and its connecting pipelines and valves . Its connection method is as follows:

[0052] Refrigerant circulation circuit: the high-pressure refrigerant outlet of the compressor module ...

Embodiment 2

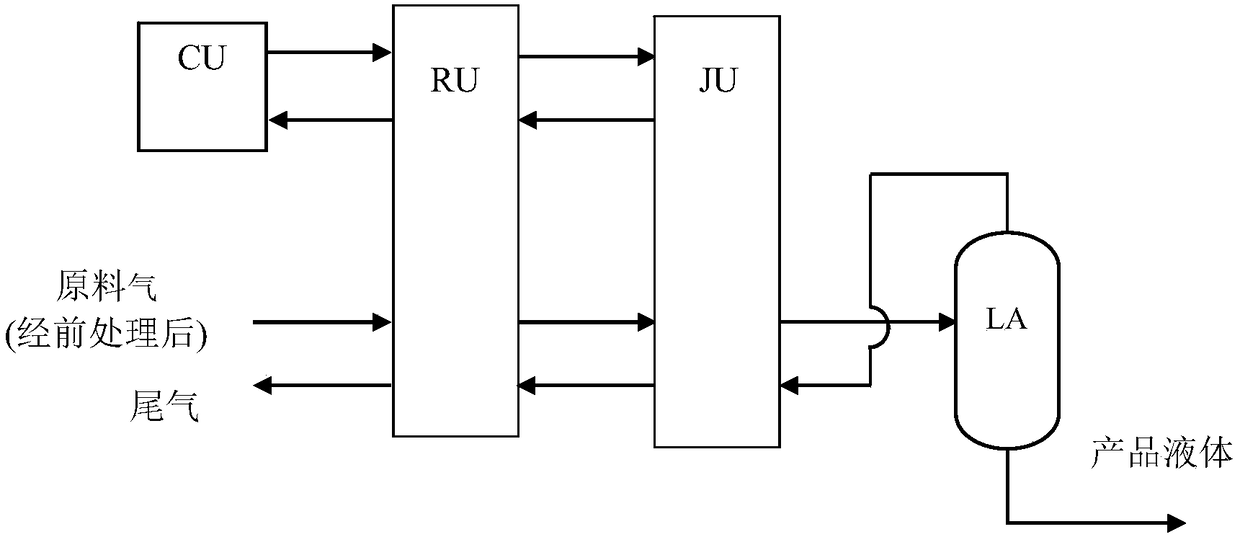

[0066] Example 2: A regenerative mixed working medium refrigeration natural gas liquefaction cycle system with a refrigeration working medium buffer adjustment tank and a simple oil separator

[0067] figure 2 It is a structural schematic diagram of the regenerative mixed refrigerant gas liquefaction cycle system of this embodiment. The compressor module CU consists of Figure 6 and Figure 7 The composition of the structure shown. The regenerative heat exchanger module RU consists of Figure 13 The composition of the structure shown. The throttle module JU consists of Figure 18 The composition of the structure shown. The regenerative mixed refrigerant gas liquefaction cycle system includes a compressor module CU, a regenerative heat exchanger module RU, a throttling module JU, a liquid storage tank LA, a gas liquefaction circuit, connecting pipelines and valves. Its connection method is:

[0068] Refrigerant circulation circuit: the high-pressure refrigerant outlet ...

Embodiment 3

[0082]Example 3: A regenerative mixed working medium refrigeration natural gas liquefaction cycle system with a refrigeration working medium buffer adjustment tank, two-stage oil separator and suction gas-liquid separator

[0083] figure 2 It is a structural schematic diagram of the regenerative mixed refrigerant gas liquefaction cycle system of this embodiment. The compressor module CU consists of Figure 6 , 7 , 11 and 12, the regenerative heat exchanger module RU consists of Figure 15 and Figure 17 Composed of the structure shown, the throttling module JU consists of Figure 18 The composition of the structure shown. The regenerative mixed refrigerant gas liquefaction cycle system consists of compressor module CU, regenerative heat exchanger module RU, throttling module JU, liquid storage tank LA, gas liquefaction circuit and its connecting pipelines and valves. Its connection method is:

[0084] Refrigerant circulation circuit: the high-pressure refrigerant outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com