Automatic capacity detecting method and device for irregular vessel cabin

A verification device and irregular technology, applied in the direction of measuring device, volume measuring instrument/method, measuring capacity, etc., can solve the problems of high labor intensity, large influence of human error, manual participation, etc., and achieve simplified working steps and high degree of automation , Improve the effect of measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

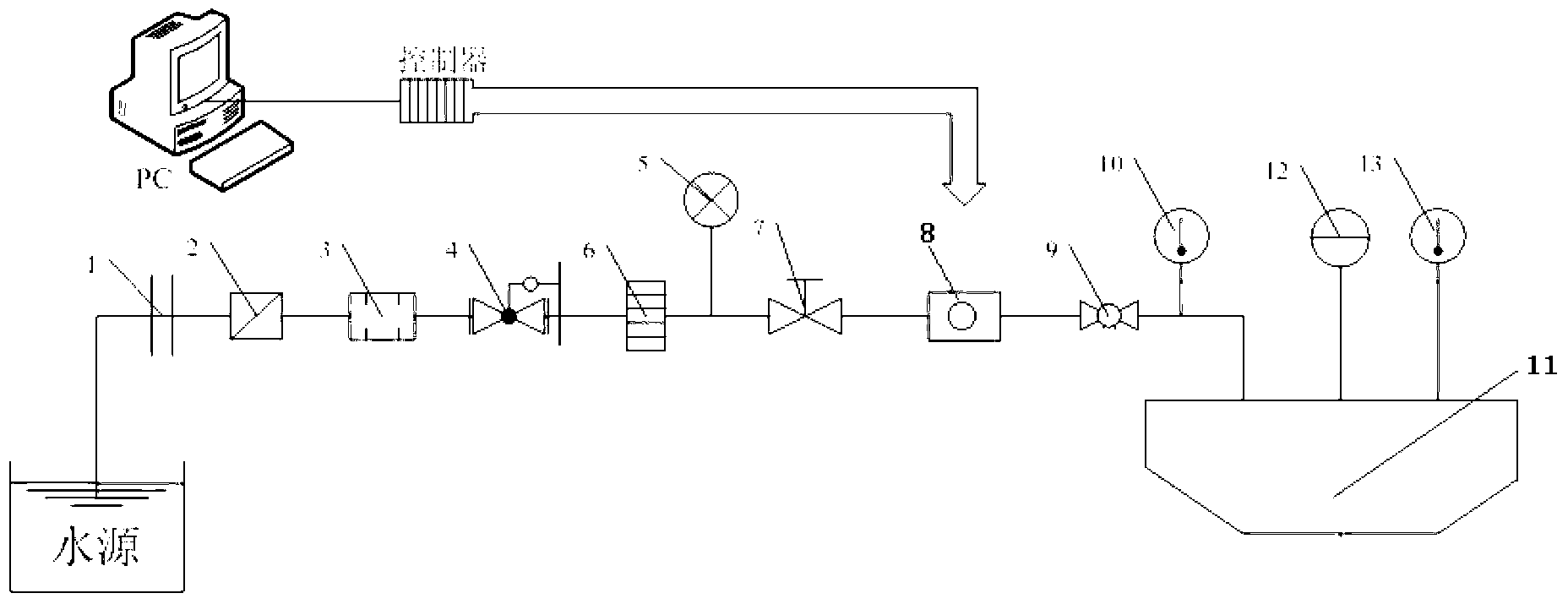

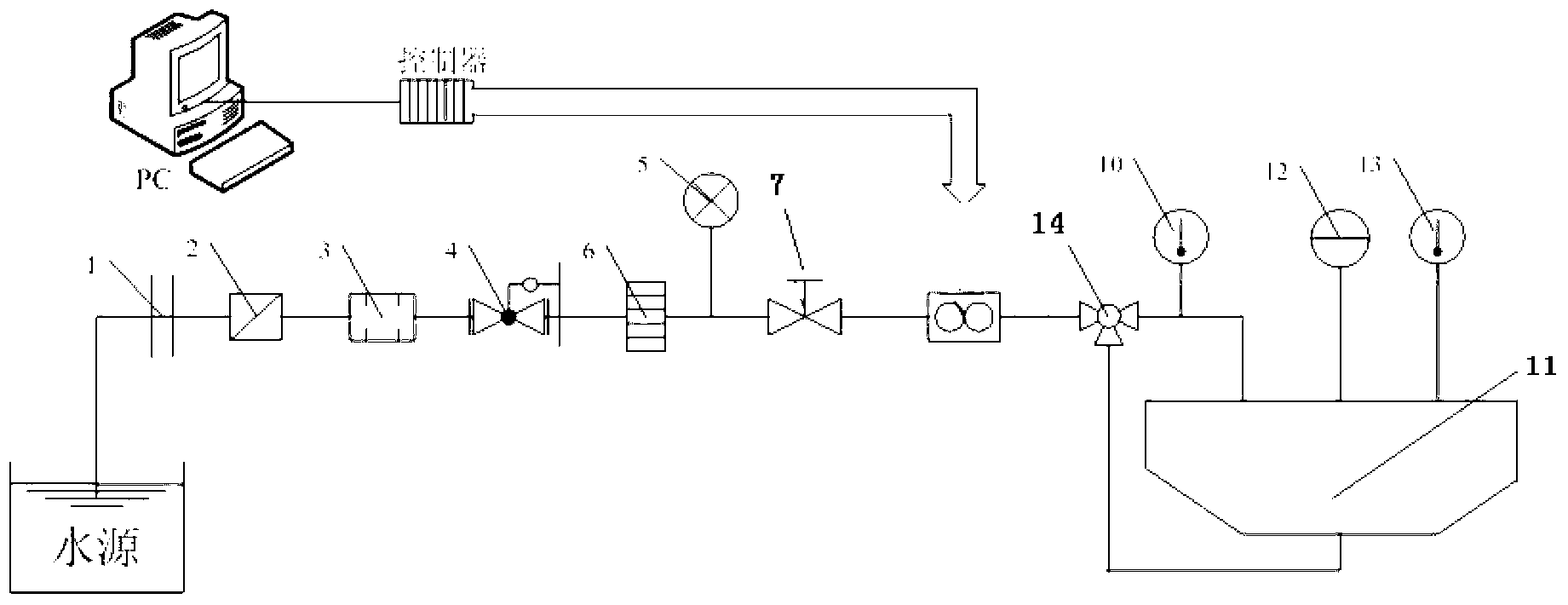

[0037] see figure 2 , The whole set of equipment is composed of two parts: the pipeline part and the control system. The measuring pipeline can be combined and installed according to the specific requirements of the on-site measuring environment, and used in sections and modules; the control system is composed of a control box and a software system, connected to multiple measuring instruments through a cable, and then connected to the computer by a data cable with an RJ45 interface , run the software system to operate and monitor the entire measurement process. After the data collection is completed, the data can be processed, analyzed and calculated directly until the verification report is output.

[0038]According to the development process, the device can be divided into two parts: hardware development and software development. The technical route of hardware development mainly includes device design, custom processing, installation and debugging, test verification and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com