Flow field observing device for oil cavity

A technology of observation device and oil cavity, which is applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc., can solve the problems of less experimental research, difficult observation, complex flow field structure, etc., and achieve accurate and reliable results , rich results, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

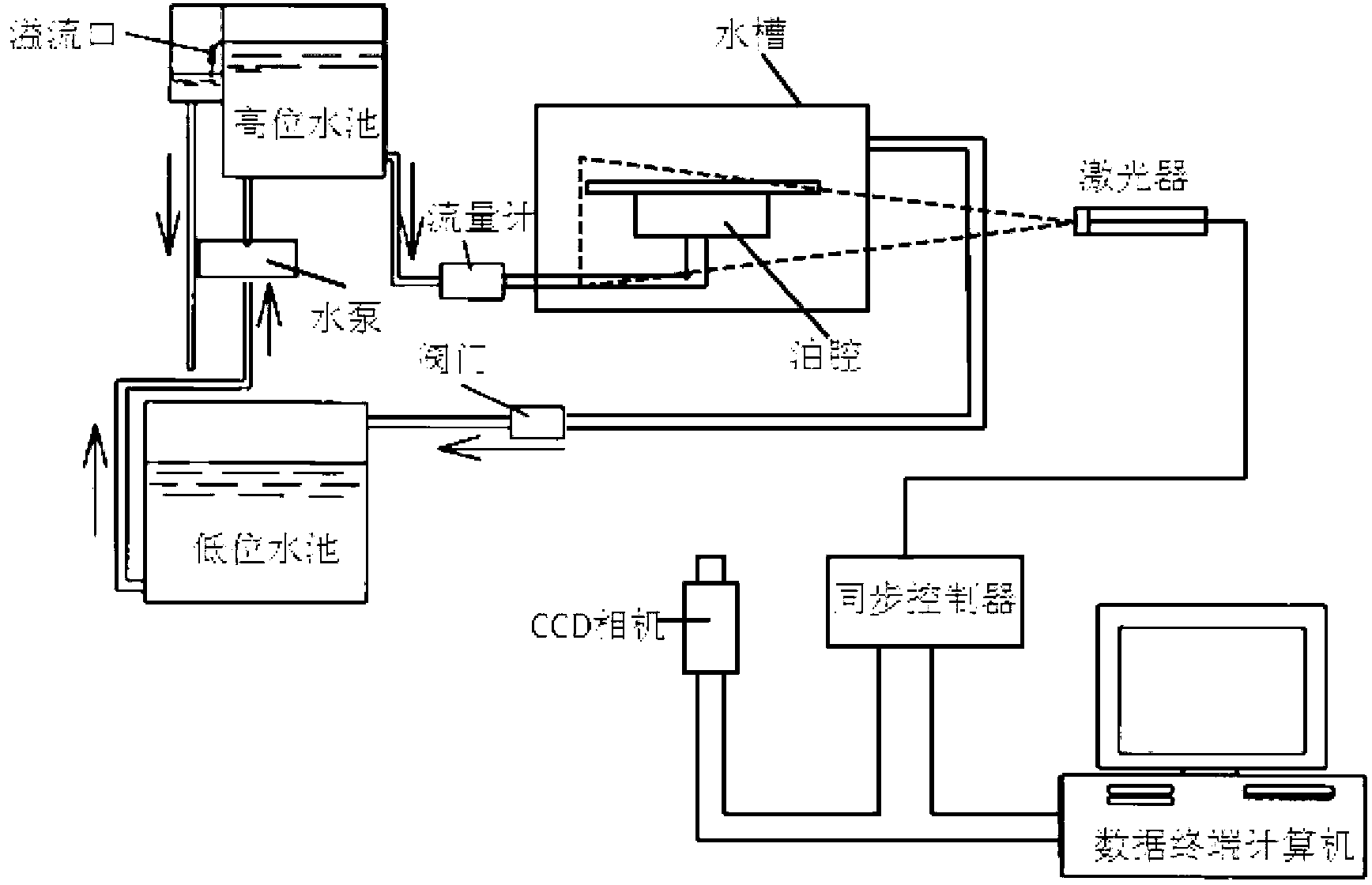

[0028] 1. According to image 3 As shown in the figure, assemble and connect the relevant devices, and place the oil chamber in the water tank. Adjust the positions of the laser, CCD camera and oil cavity so that the camera can clearly capture the relevant areas.

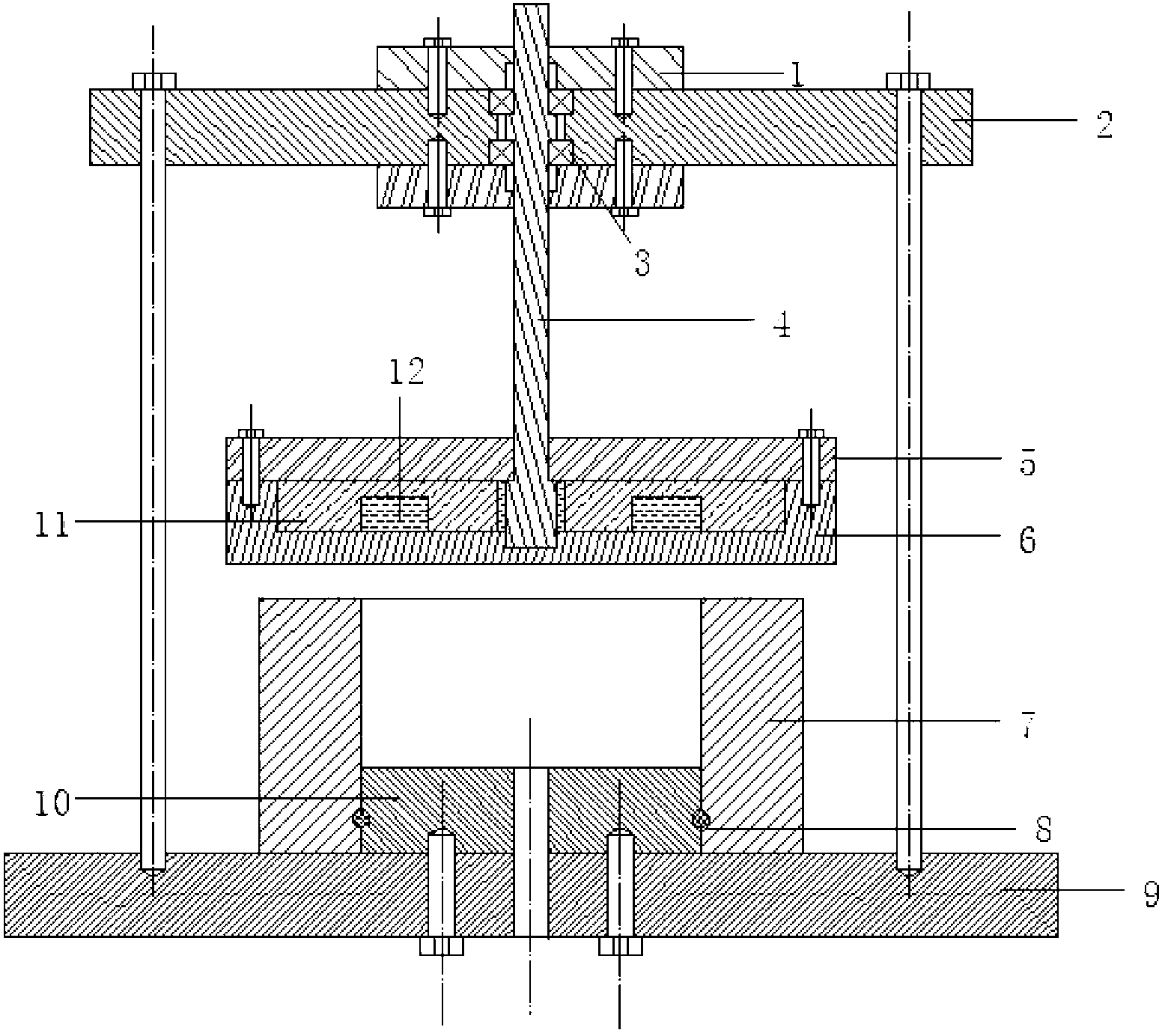

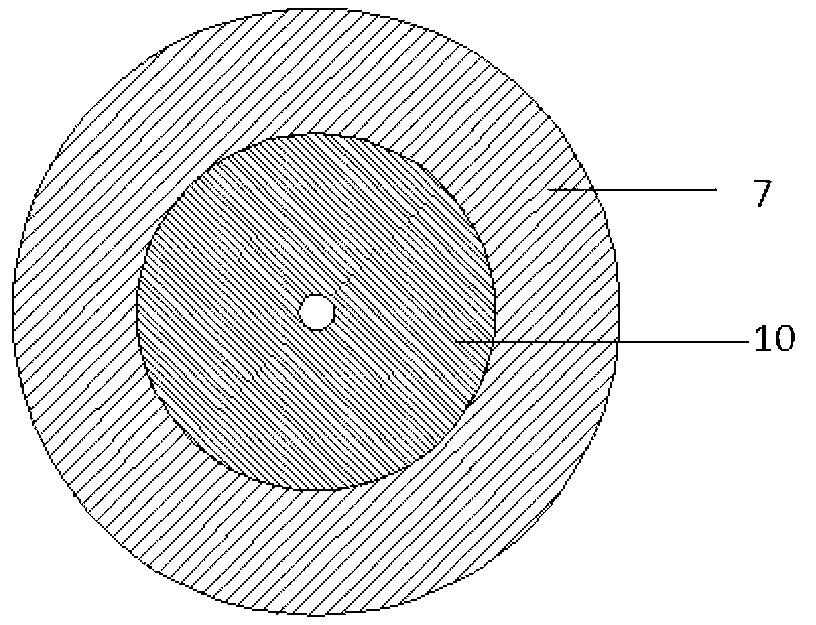

[0029] The oil chamber includes a base boss 10 , an annular side wall 7 and a bearing platform 6 . The base boss 10 is fixed on the base 9 by bolts, and a pipe is embedded in a through hole in the center of the two as the inlet pipe of the oil chamber. The annular side wall 7 is sleeved on the periphery of the base boss 10 and sealed by a sealing ring 8 .

[0030] There are supporting platform 2, main shaft 4 and supporting platform 6 above the annular side wall 7 from top to bottom; ; The main shaft 4 is connected with an external motor; There is no contact between the bearing platform 6 and the annular side wall 7 to form a gap;

[0031]The carrying platform 6 is fixed on the casing 5 by bolts, and the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com