A test system for testing rotor type energy recovery device

A technology of energy recovery device and test system, which is applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problems of inconvenient testing, high cost, certain problems in accuracy and reliability, and achieve compact structure. , reliable use, comprehensive performance evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

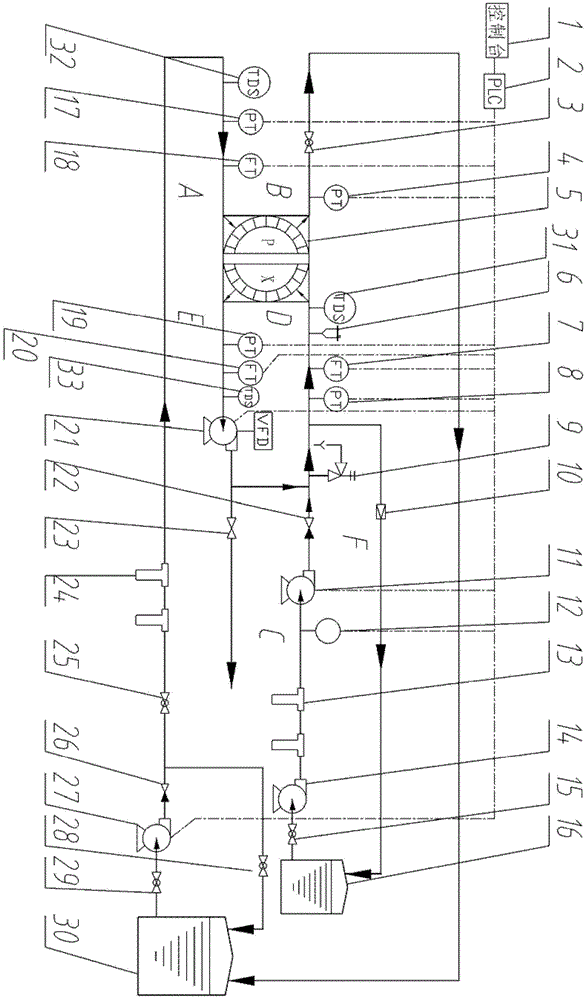

Method used

Image

Examples

Embodiment 1

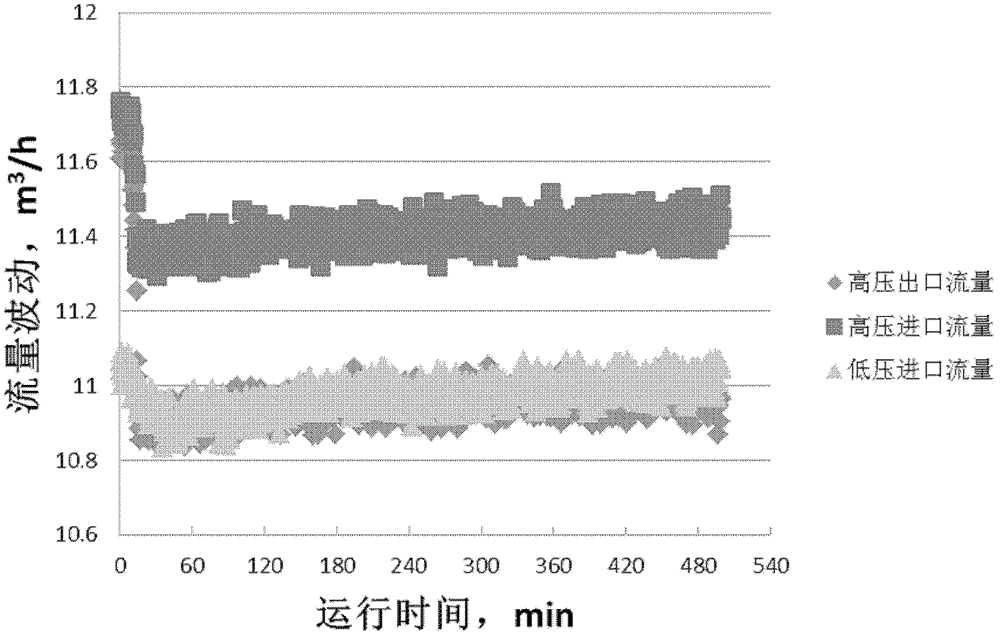

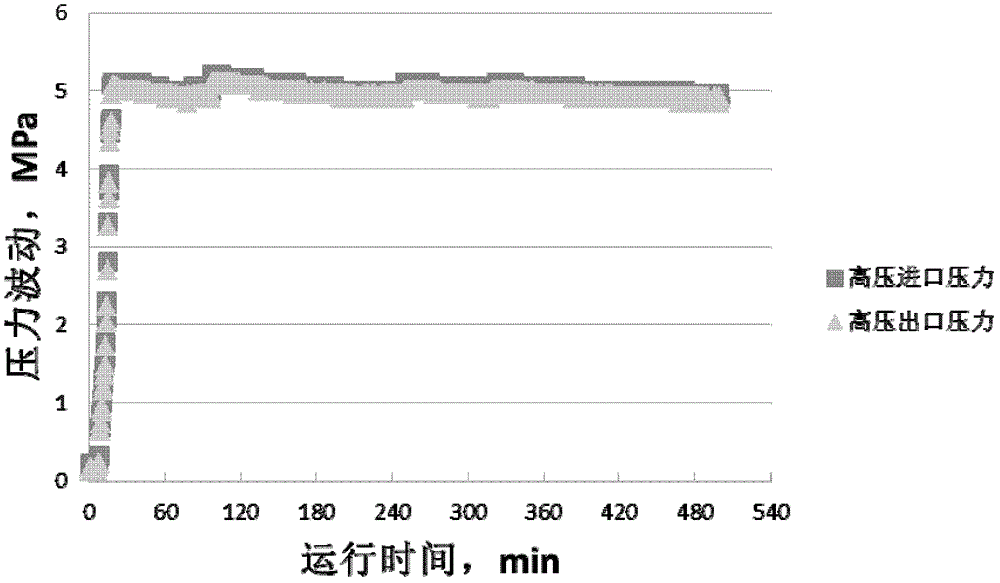

[0063] In this embodiment, the processing capacity is 10-20m 3 / h of the rotor energy recovery device 5 at a flow rate of 10m 3 / h, the performance test of the energy recovery device was carried out under the condition of operating pressure of 5.0MPa.

[0064] First, after the preparations for the test system are confirmed to be correct, start the water supply pump 15 to fill the high-pressure pipeline with water; open the exhaust valve 6 to empty the air in the high-pressure pipeline; then start the booster pump 22 to increase the rotor speed , and further exhaust through the exhaust valve 6;

[0065] Next, start the water supply pump 28 again, and adjust the water supply flow of the low-pressure pipeline to the required flow value by adjusting the opening and closing degree of the regulating valve 28 at the outlet of the pump;

[0066] Next, adjust the frequency converter frequency of the booster pump 22 to control the flow of concentrated brine in the high-pressure pipeli...

Embodiment 2

[0071] In this embodiment, the processing capacity is 20-30m 3 / h of the rotor energy recovery device 5 at a flow rate of 20m 3 / h, the performance test of the energy recovery device was carried out under the condition of operating pressure of 5.5MPa.

[0072] The operation steps of this embodiment are the same as those of Embodiment 1, so they will not be described in detail here.

[0073] After testing, the results show that the energy recovery efficiency of the energy recovery device reaches an average of 96%, and the lubrication flow rate is less than 0.6m 3 / h, the degree of mixing is less than 4%.

Embodiment 3

[0075] In this embodiment, the processing capacity is 30-40m 3 / h of the rotor energy recovery device 5 at a flow rate of 30m 3 / h, the performance test of the energy recovery device was carried out under the condition of operating pressure of 5.5MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com