Step-by-step grading sampling method suitable for carbonatite sample

A carbonate rock and sample technology, applied in the field of geological exploration, to avoid physical and chemical pollution and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

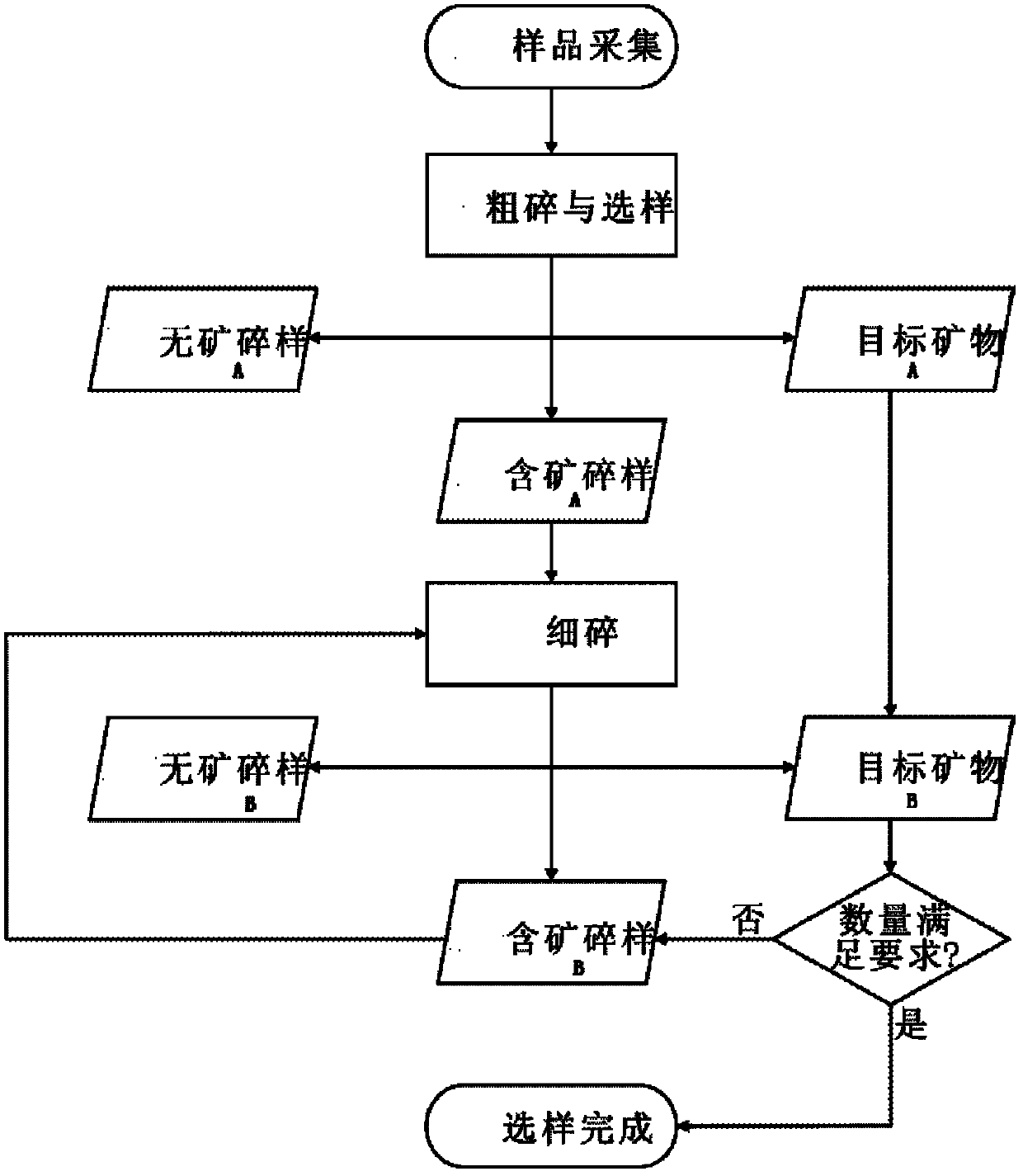

[0034] In the sample collection step, the dolomite samples containing the target mineral as dolomite are collected, and the samples are roughly crushed by means of mechanical crushing using a geological hammer. Blocks, including larger-sized ore-bearing crushed samples, target minerals, and fine powders that cannot be distinguished from surrounding rocks and target minerals after crushing, after sieving to obtain powder-free ore-bearing crushed samples, select the target minerals under binoculars , can get target minerals and ore-bearing crushed samples. So far, the sample coarse crushing step is completed.

[0035] Use a geological hammer to mechanically crush the ore-bearing crushed samples at the above coarse crushing stage to obtain 0.2-0.5 cm ore-bearing crushed samples, and then sieve and separate the ore-bearing crushed samples to obtain target minerals and ore-bearing crushed samples. Combine the target minerals obtained in the fine crushing stage of the sample and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com