Mixed colloidal electrolyte and preparation technology thereof

A colloidal electrolyte and a preparation process technology, applied in the field of mixed colloidal electrolyte and its preparation process, can solve the problems of insufficient shear force, high viscosity, easy hydration and delamination, etc., and achieve easy perfusion, moderate gel strength, and thixotropy. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

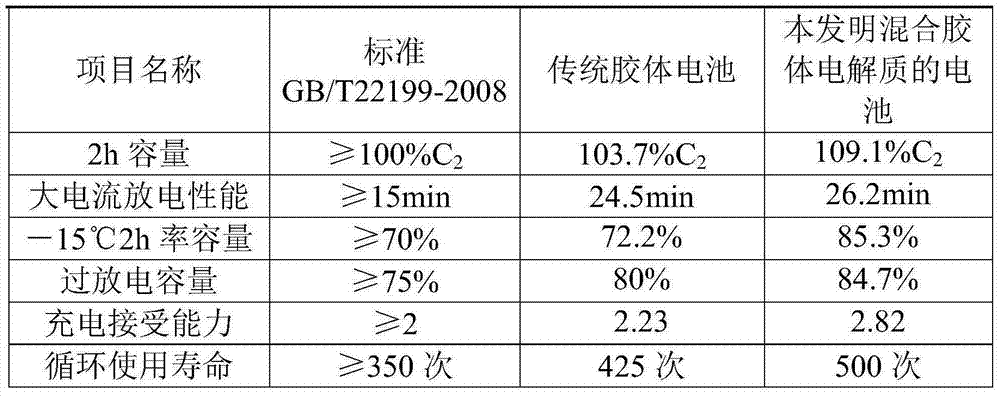

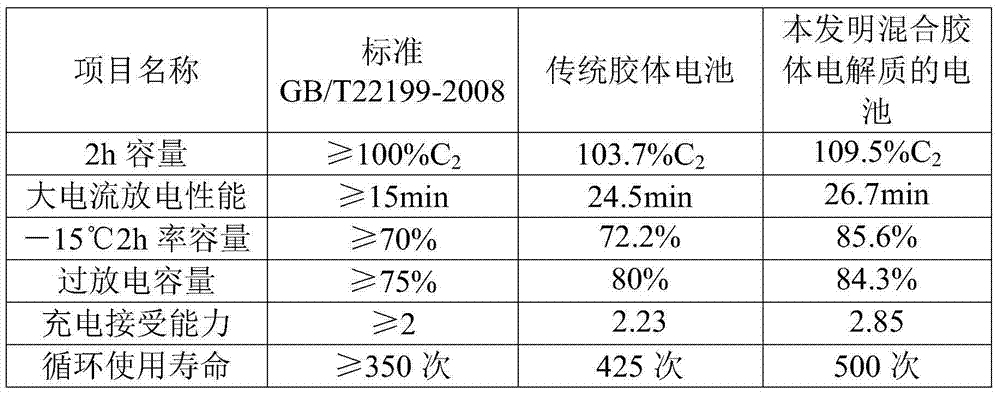

Embodiment 1

[0033] One, the preparation of silicon powder aqueous solution:

[0034] a. Add 200 kg of deionized water with a conductivity of 1.78 μs / cm into a bucket with a stirring device, that is, a rotating speed of 2880 rpm,

[0035] b. Add 1Kg of analytically pure glycerin to the bucket with stirring device,

[0036] c, add 8Kg precipitated silica in the bucket with stirring device,

[0037] d. Completely inhale the mixed fumed silica into pure water,

[0038] e. Turn on the mixer, the speed of the mixer is 2880 rpm, the length of the blade of the mixer is about 200 mm, and stir for 15 minutes, so that the precipitated silica and fumed silica are fully dispersed in the solution under stirring.

[0039] f. Add 15g of analytically pure polyacrylamide into a barrel with a stirring device, and stir for 10 minutes to make the solution evenly stirred and set aside.

[0040] Two, the preparation of mixed acid:

[0041] g. Add 500Kg of deionized water with a conductivity of 1.78μs / cm int...

Embodiment 2

[0058] One, the preparation of silicon powder aqueous solution:

[0059] a. Add 200 kg of deionized water with a conductivity of 1.78 μs / cm into a bucket with a stirring device, that is, a rotating speed of 2880 rpm,

[0060] b. Add 1.2Kg of analytically pure glycerin to the bucket with stirring device,

[0061] c, add 12Kg precipitated silica in the bucket with stirring device,

[0062] d. Completely inhale the mixed fumed silica into pure water,

[0063] e. Turn on the mixer, the speed of the mixer is 2880 rpm, the length of the blade of the mixer is about 200 mm, and stir for 15 minutes, so that the precipitated silica and fumed silica are fully dispersed in the solution under stirring.

[0064] f. Add 20g of analytically pure polyacrylamide into a barrel with a stirring device, and stir for 10 minutes to make the solution evenly stirred and set aside.

[0065] Two, the preparation of mixed acid:

[0066] g. Add 500Kg of deionized water with a conductivity of 1.78μs / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com