Aluminum wheel coating method and aluminum wheel

A coating method and technology for aluminum alloys, which are applied in chemical instruments and methods, metal material coating processes, and devices for coating liquids on surfaces, etc. and other problems, to achieve excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] Hereinafter, the present invention will be described with reference to examples, but the present invention is not limited by these examples.

[0073] [Manufacturing method of anticorrosion coating composition]

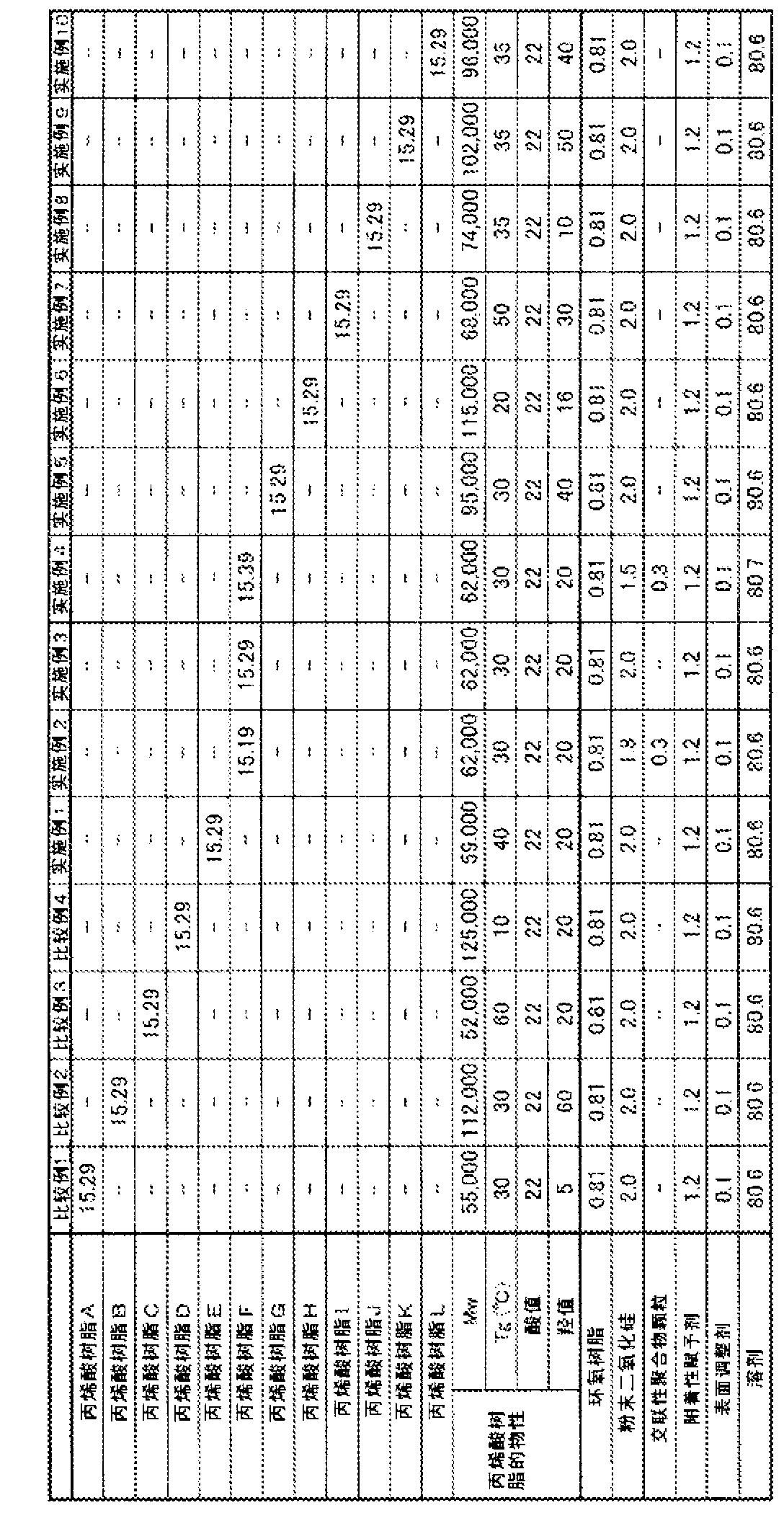

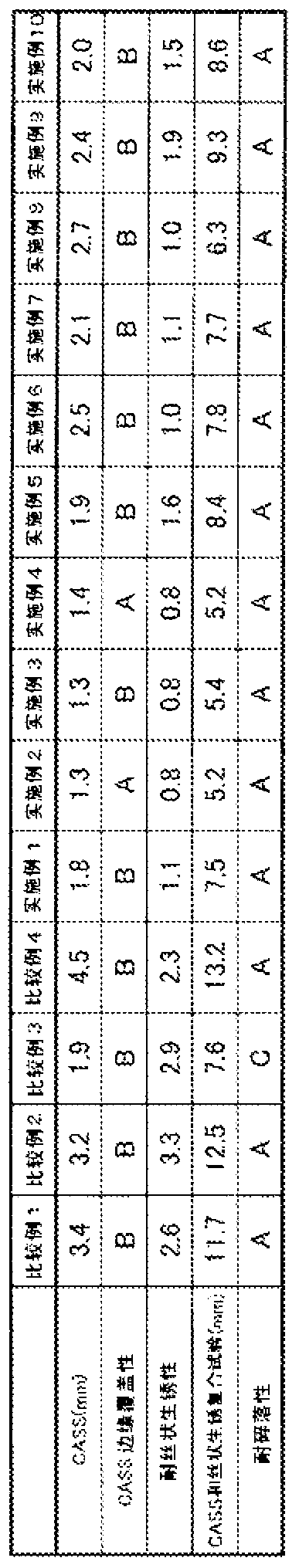

[0074] Prepare a solvent obtained by mixing a hydrocarbon solvent / alcohol solvent / ester solvent (hereinafter referred to simply as a mixed solvent) at the compounding ratio (parts by mass) described in Table 1. The acrylic resin, powdered silica, and mixed solvent are expressed as Mix in the ratio described in 1, and disperse the powdered silica to a fineness meter of 5 μm or less by a batch disperser using glass beads (JIS K-5600-2-5). The dispersion was taken out into another container, and the epoxy resin varnish was added according to Table 1 while stirring, and then the crosslinkable polymer particle solution and additives were added in the same manner to prepare each anticorrosion coating composition.

[0075] [Table 1]

[0076]

[0077] The numerical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com