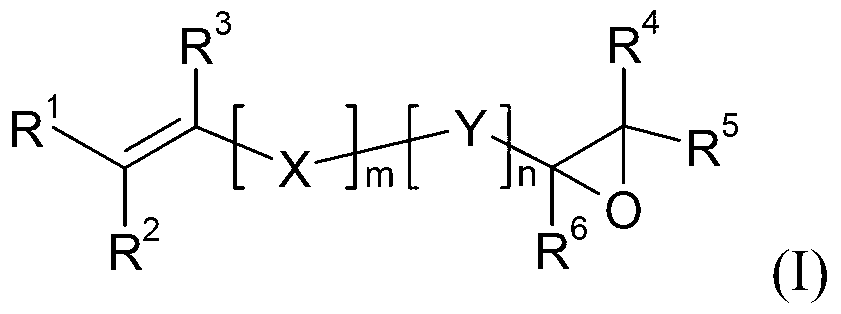

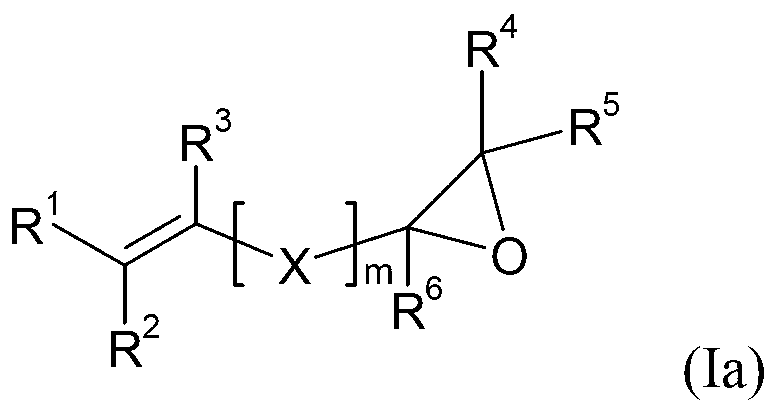

Compositions that can be vulcanized and that are based on nitrile rubbers containing epoxy groups

A technology of epoxy group and nitrile rubber, which is applied in the field of nitrile rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

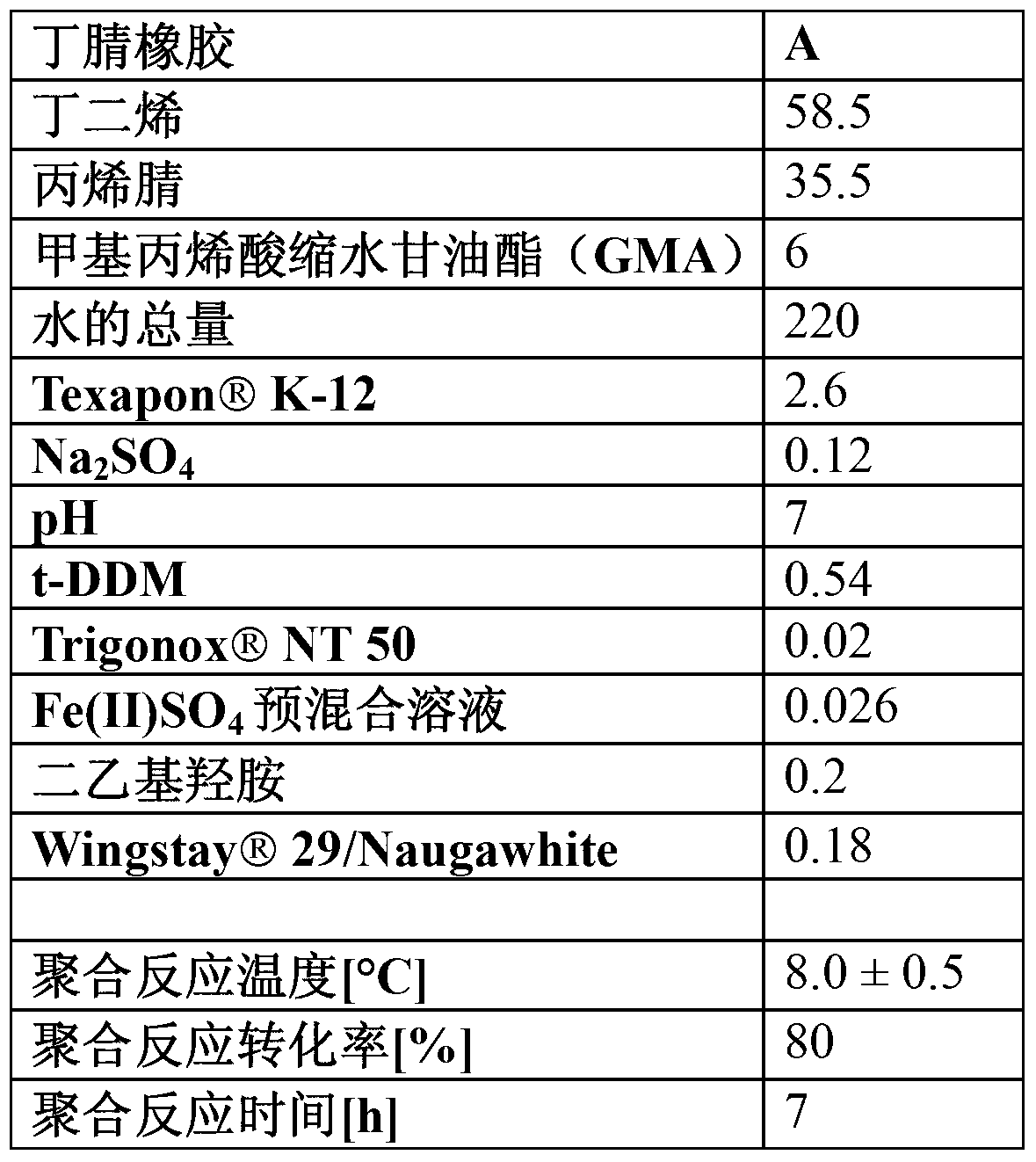

Examples

example

[0191] The nitrogen content for the determination of the acrylonitrile content ("ACN content") of the optionally fully or partially hydrogenated nitrile rubbers containing epoxy groups according to the invention is according to the Kjeldahl method according to DIN 53625 Measured. Owing to the content of polar comonomers, optionally hydrogenated nitrile rubbers containing epoxy groups are generally >85% by weight soluble in methyl ethyl ketone at 20°C.

[0192] The glass transition temperature and its so-called entry and exit points are determined by differential scanning calorimetry (DSC) according to ASTM E1356-03 or DIN11357-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com