Water-jetting limescale removing method and device

A water jet and scale technology, applied in boiler cleaning devices, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of environmental pollution by chemical cleaning agents, unsatisfactory chemical cleaning effect, and scale removal rate of less than 50%. , to achieve the effect of improving the quality of removal, avoiding environmental pollution and waste of water resources, and improving the efficiency of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

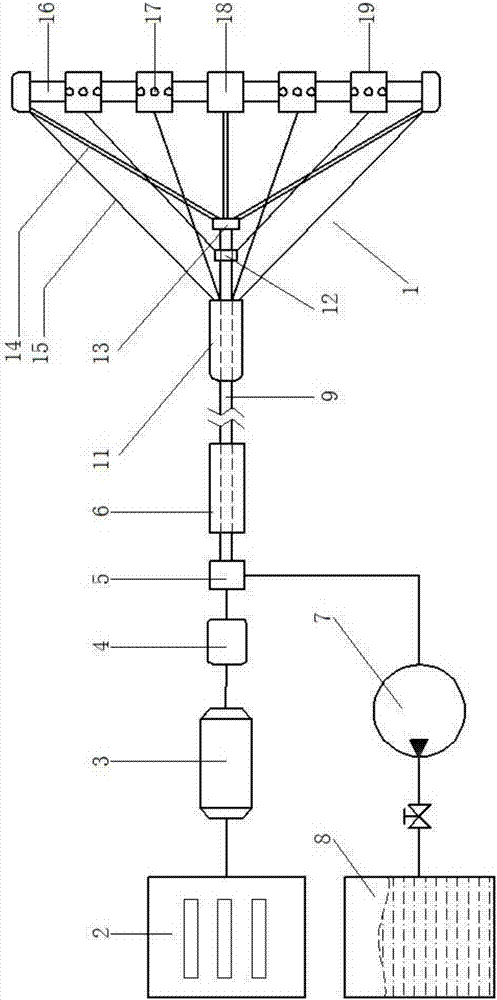

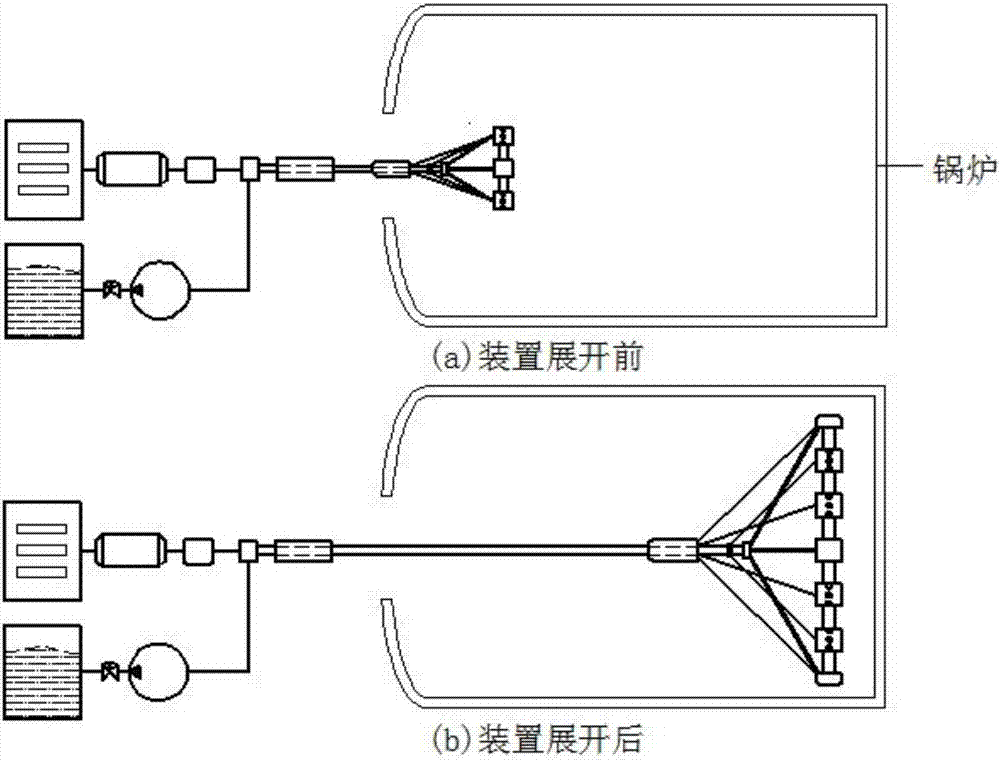

[0020] Specific embodiment 1: see attached figure 2 , which is a schematic diagram of the present invention specifically applied to boiler scale removal. The electric control box (2) controls the stretcher (11) to move along the guide rod (9) to reduce the opening degree of the umbrella-shaped rotary spraying device (1), so that it enters the boiler with a small posture; the umbrella-shaped rotary spraying device After the device (1) enters the boiler, the stretcher (11) moves along the guide rod (9) again so that the umbrella-shaped rotary spraying device (1) is opened to prepare for cleaning. The water pump (7) pressurizes the water in the water storage tank (8) and outputs it, and the output high-pressure water jet is introduced into the guide rod (9) through the water jet interface (5), and then drained to the diverter ( 13), and then reach the annular nozzle device (19) through the guide pipe (14), the guide chamber (18), the annular telescopic tube (16), etc., and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com