Method for operating a quantity-regulated internal combustion engine and internal combustion engine

A quantity control, internal combustion engine technology, applied in the direction of internal combustion piston engine, engine control, combustion engine, etc., can solve the problem of insufficient efficiency improvement of internal combustion engine, and achieve favorable effects of fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

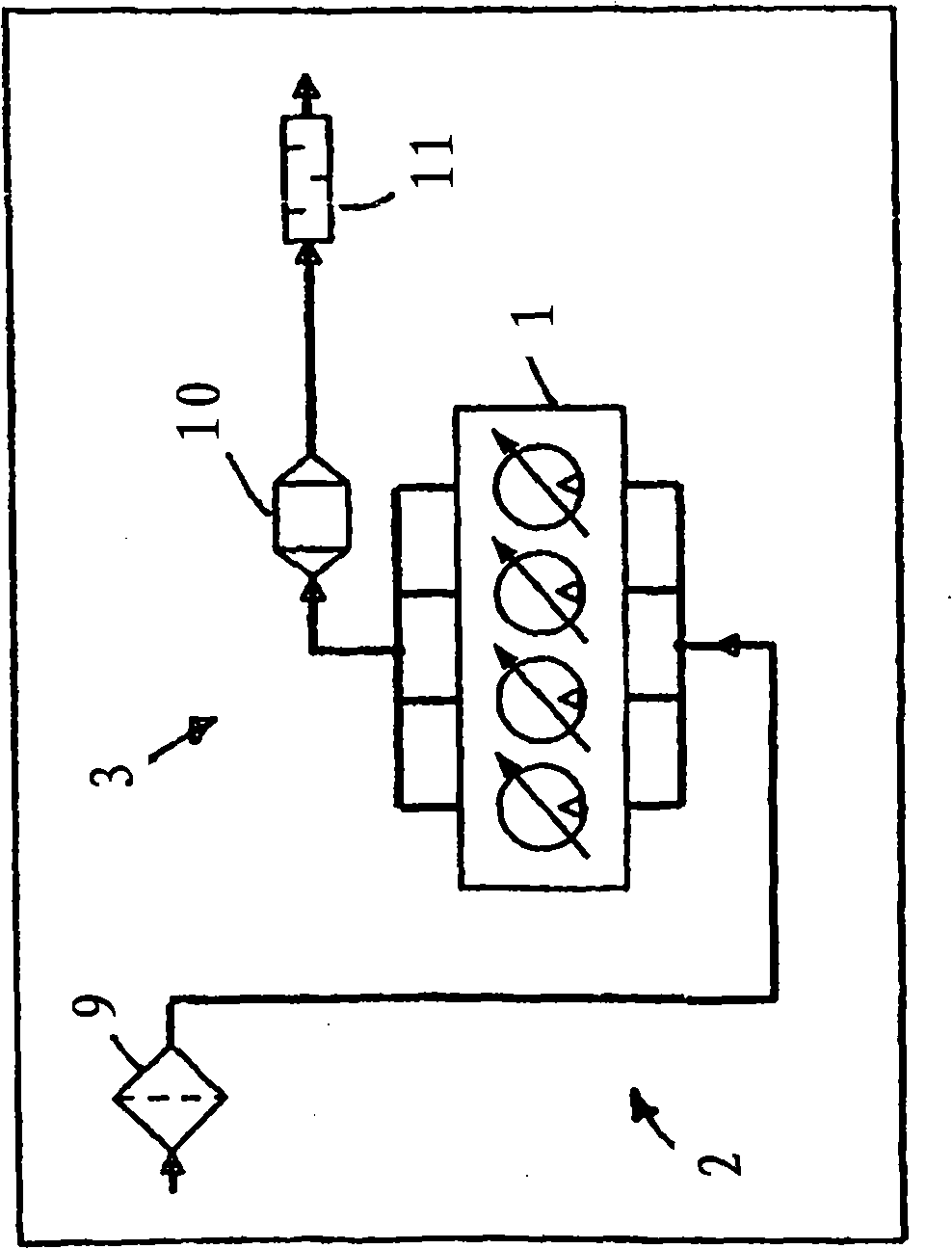

[0031] In the following, the same reference numerals are used for the same structural elements in all figures.

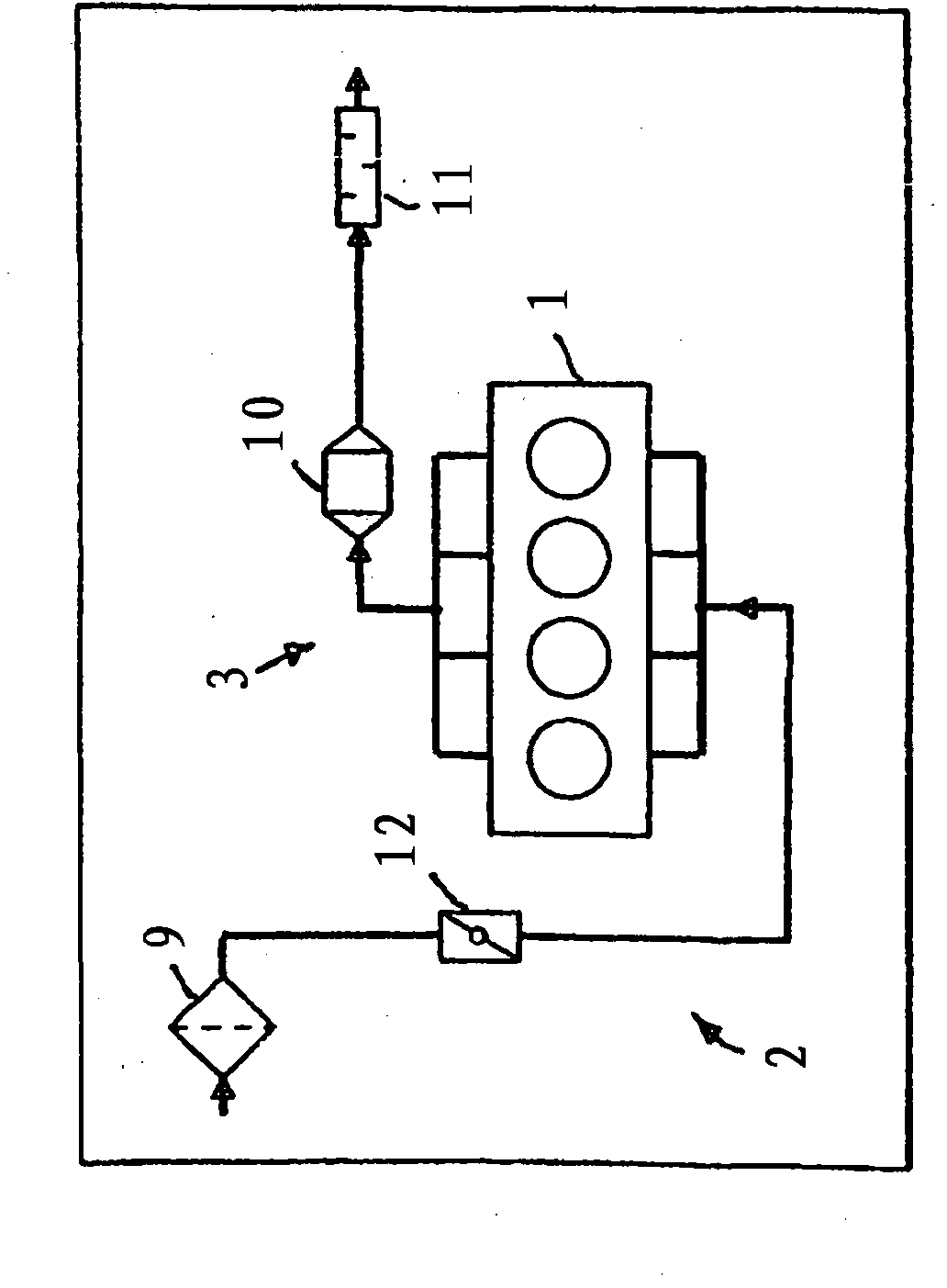

[0032] figure 1 A schematic illustration of an internal combustion engine according to the prior art with load control via a throttle valve. Via the intake system 2 , an internal combustion engine 1 with cylinders symbolized by four circles draws in combustion air which first passes through an intake muffler 9 and then past a throttle element 12 , such as a throttle valve or cylinder slide valve. The inhaled combustion air is then combusted with the fuel in the cylinder and discharged again as exhaust gas through the exhaust line 3 in which an exhaust gas cleaning device 10 for cleaning the exhaust gas and Followed by a muffler 11.

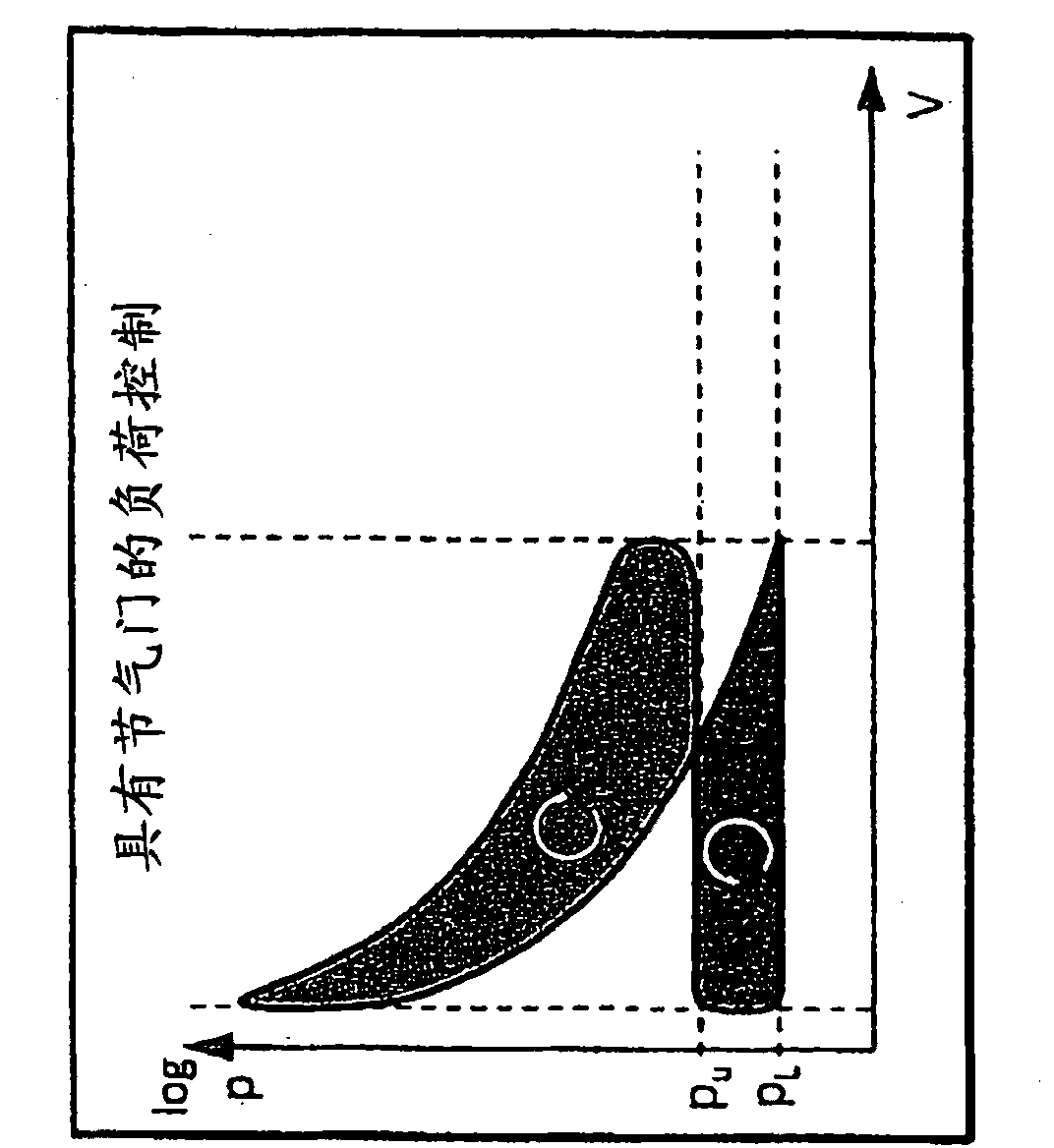

[0033] The conventional load control of the quantity-controlled (λ=1) internal combustion engine 1 is achieved via the throttle element 12 by “dilution” of the intake air in the intake line upstream of the intake valves of the intern...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap