Device for controlling temperature of an optical element

A technology of optical components and controllers, applied in the field of temperature devices, can solve problems such as thermal instability of the system, and achieve the effects of avoiding interference, good control, and preventing thermal drift effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

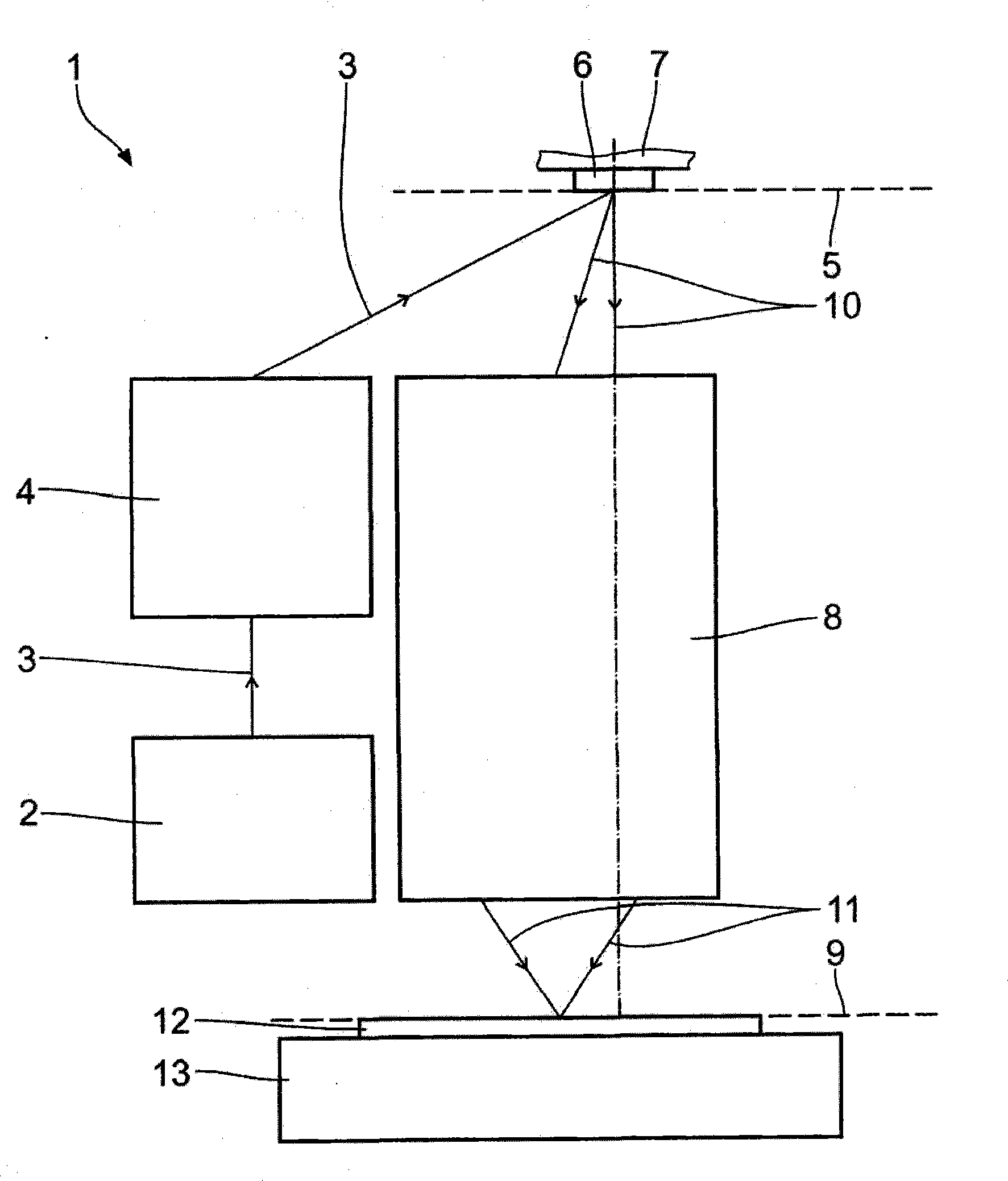

[0075] figure 1 An outline part of a microlithography tool 1 for producing microstructured components such as semiconductor microchips is schematically shown.

[0076] The microlithography tool 1 has an illumination source 2 emitting an illumination beam 3 . figure 1 In , only the chief ray of the illumination beam 3 is shown. The illumination source 2 is, for example, an extreme ultraviolet (EUV) source emitting radiation with a wavelength between 5 nm and 30 nm. Advantageously, the illumination source 2 is a plasma EUV source.

[0077] After being emitted from the illumination light source 2 , with the aid of the illumination optics 4 , the illumination beam 3 is formed and guided. The illumination light source 2 and the illumination optics 4 are part of the illumination system of the microlithography tool 1 . The illumination optical system 4 includes several figure 1 Optical mirrors not shown. The illumination optics 4 serve to provide specific illumination of the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com