Two-roll vertical roll mill provided with hydraulic horizontal press rolls

A vertical roll mill and pressure roll technology, which is applied in the field of two-roll vertical roll mills used in the metallurgical industry, can solve the problems of not meeting the quality requirements of rectangular sections, waste of materials, waste of mechanical processing, etc., achieving significant social benefits, convenient use, and reduced The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

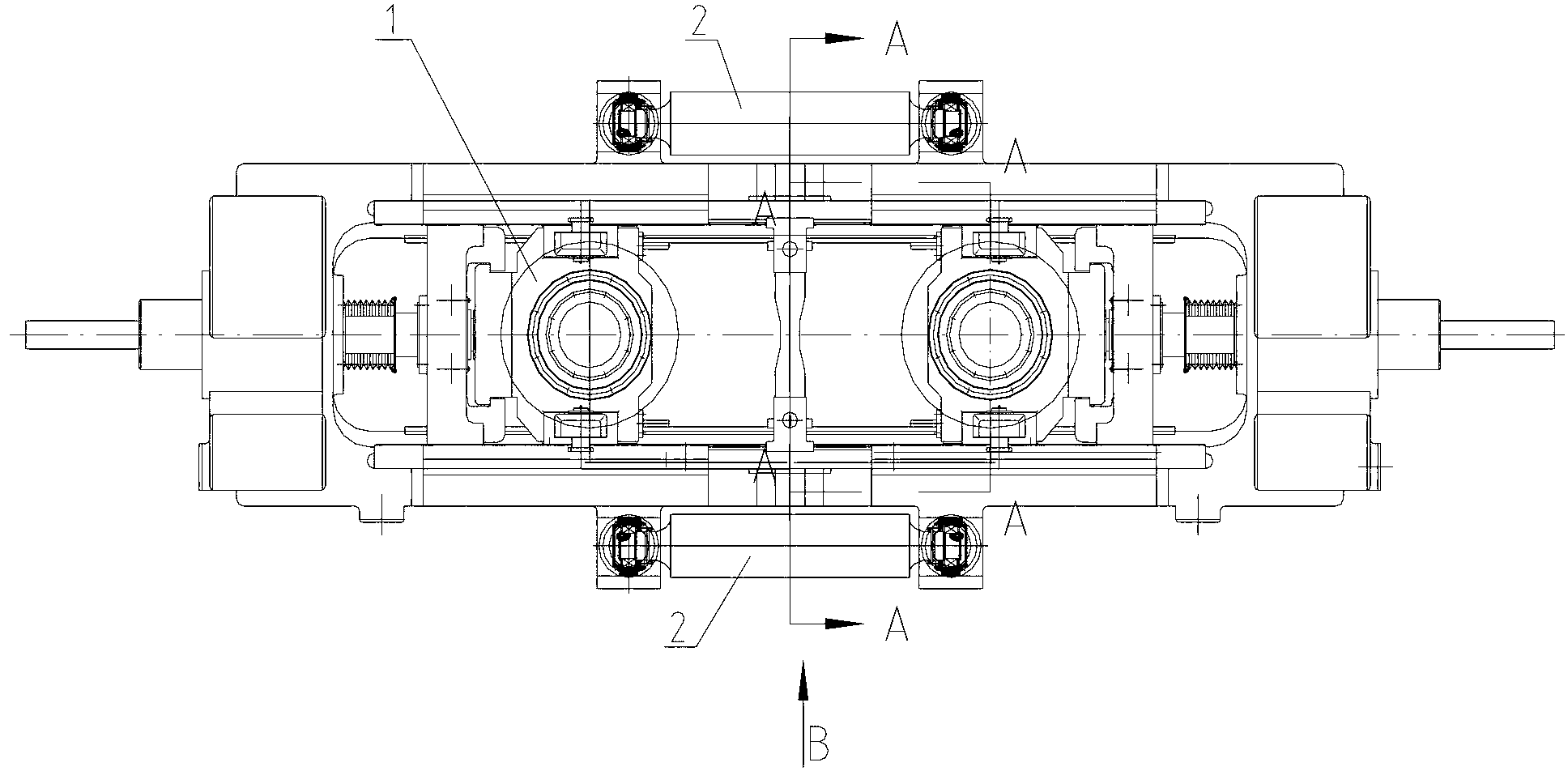

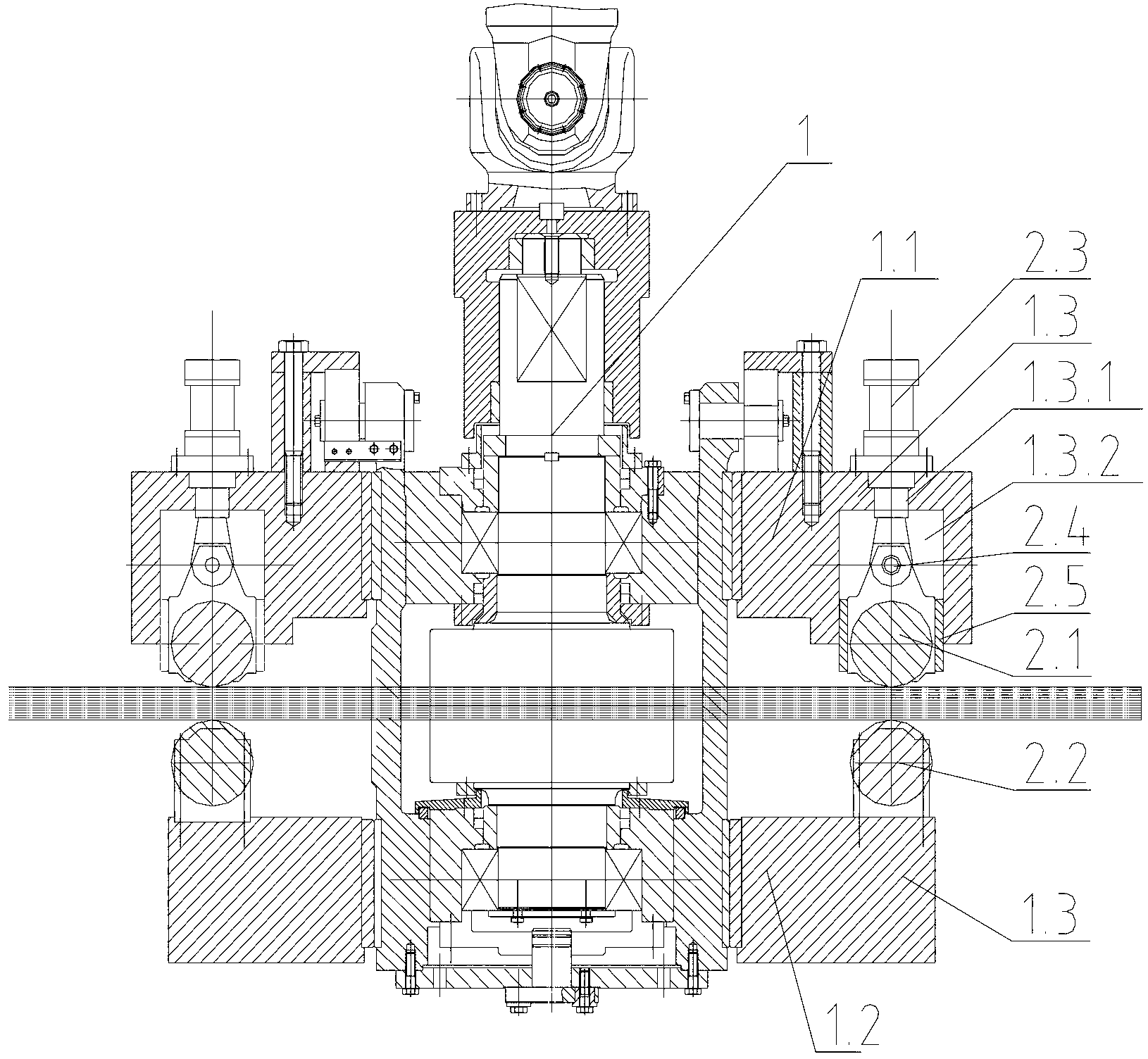

[0024] The specific embodiment of the present invention is shown in the accompanying drawings, which is characterized in that an upper archway 1.1 and a lower archway 1.2 are installed on the two-roll vertical roller mill body 1; the upper archway 1.1 is cast with an upper boss 1.3 and a lower archway 1.2 The upper casting has a lower boss 1.4; the upper boss 1.3 is processed with a round hole 1.3.1, and the lower part is processed with a square hole 1.3.2; a horizontal pressure roller device 2 is installed between the upper boss 1.3 and the lower boss 1.4.

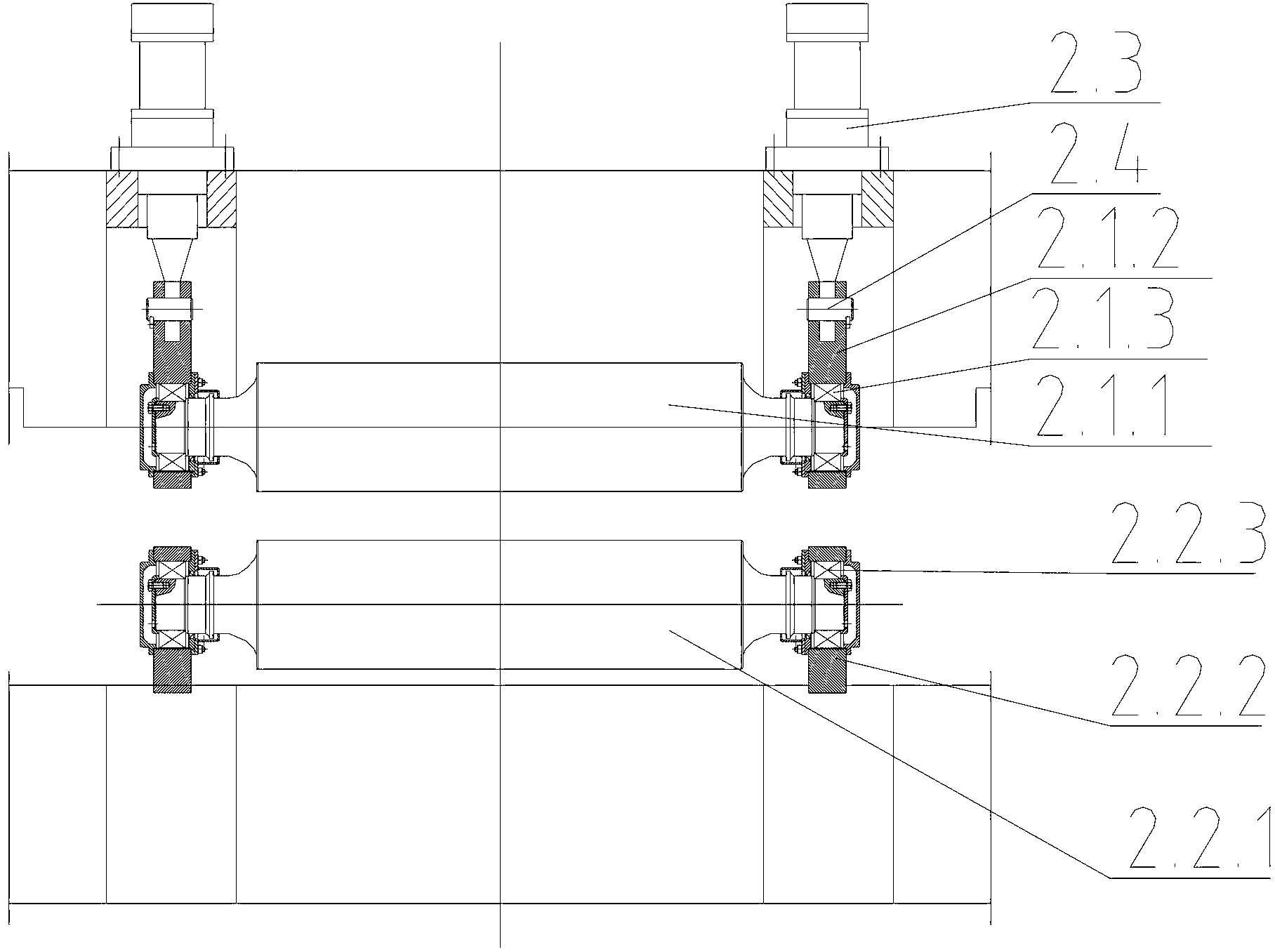

[0025] The horizontal pressure roller device 2 includes upper roller assembly 2.1, lower roller assembly 2.2, hydraulic cylinder 2.3, pin shaft 2.4 and slide plate 2.5; Connect with the upper roller assembly 2.1; the upper roller assembly 2.1 is installed on the slideway in the square hole 1.3.2 of the upper boss 1.3 through the slide plate 2.5; the lower roller assembly 2.2 is installed on the lower boss 1.4.

[0026] Up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com