Healthcare corncob mattress

A technology of corncobs and mattresses, applied in mattresses, spring mattresses, stuffed mattresses, etc., can solve the problems of insufficient comfort, no health care function, easy to be deformed by moisture, etc., to increase comfort, easy to degrade, and replace The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

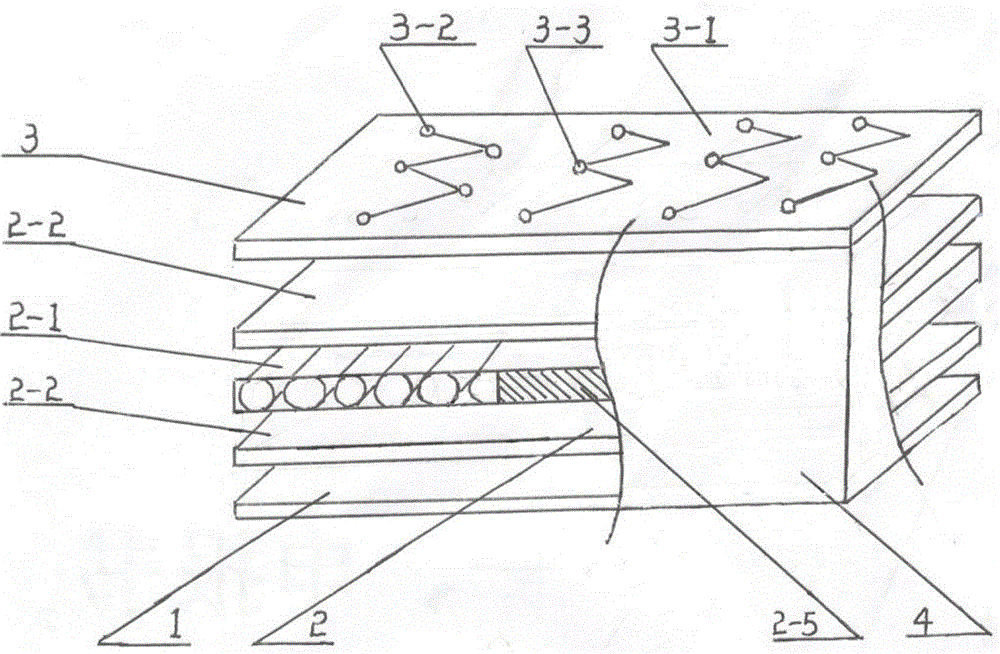

[0030] Embodiment 1: A kind of corncob health care mattress comprises bottom layer (1), middle layer (2), surface layer (3) and side wall layer (4) constituted from bottom to top, and described bottom layer (1) is made of corn bread The husk is the braided layer of the raw material, and its production process is as follows: the corn husk is processed, and the processing procedure is to first remove the debris and impurities, and then send it to the digester for cooking and softening treatment. During the cooking process, a softener can be added to strengthen the softening effect. Finally, it is dried and woven into the desired size.

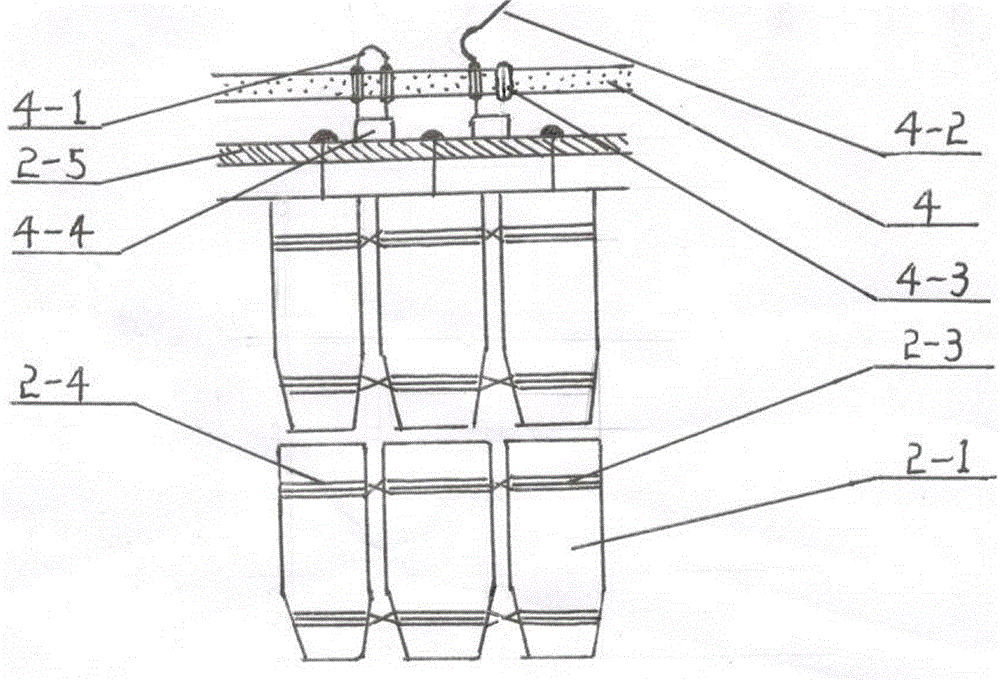

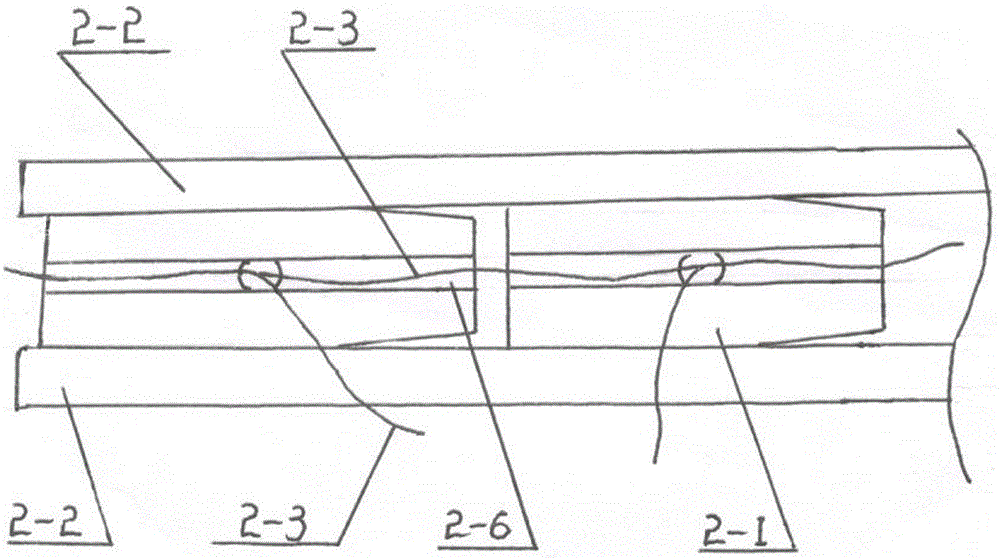

[0031] The middle layer (2) is composed of a mandrel layer (2-1) located in the middle and an adhesive layer (2-2) located on the upper and lower layers, and the mandrel layer (2-1) is composed of several corncob planes Arranged in the same shape, twisted and braided by braided ropes (2-3), specifically: the corncobs are screened to form basicall...

Embodiment 2

[0038] Embodiment 2: A kind of corncob health care mattress comprises bottom layer (1), middle layer (2), surface layer (3) and side wall layer (4) constituted by bottom up,

[0039]The bottom layer (1) is a kneaded braided layer made of wheat straw and straw as raw materials. The production process is as follows: after the wheat straw and straw are decontaminated and decontaminated, they are rolled by a roller press at a rolling speed of 18-25m / min , put it in boiling water at a temperature of 100-120 degrees and cook for 40-60 minutes after being rolled, then dry it to make the water content 10-12%, and finally send it to the straw kneading silk for kneading treatment, and the kneading machine turns Returning speed is 2500 rev / min, and the length of rubbing silk extraction is ≥5cm, and the diameter is 1-3mm straw silk, and the straw silk is braided into a braid shape and then fixed to the required size with a rope.

[0040] The middle layer (2) is composed of a mandrel layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com