Multi-unit synchronous tension control system and method for pull steel wire rope cleaning and maintenance line

A traction wire rope and tension control technology, which is applied in the field of multi-unit synchronous tension control system, can solve the problems such as the unstable tension change of the traction wire rope cleaning and maintenance line, achieve stable and reliable detection results, improve the effect of coarse brushing, and improve the maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The invention is described in detail below in conjunction with accompanying drawing:

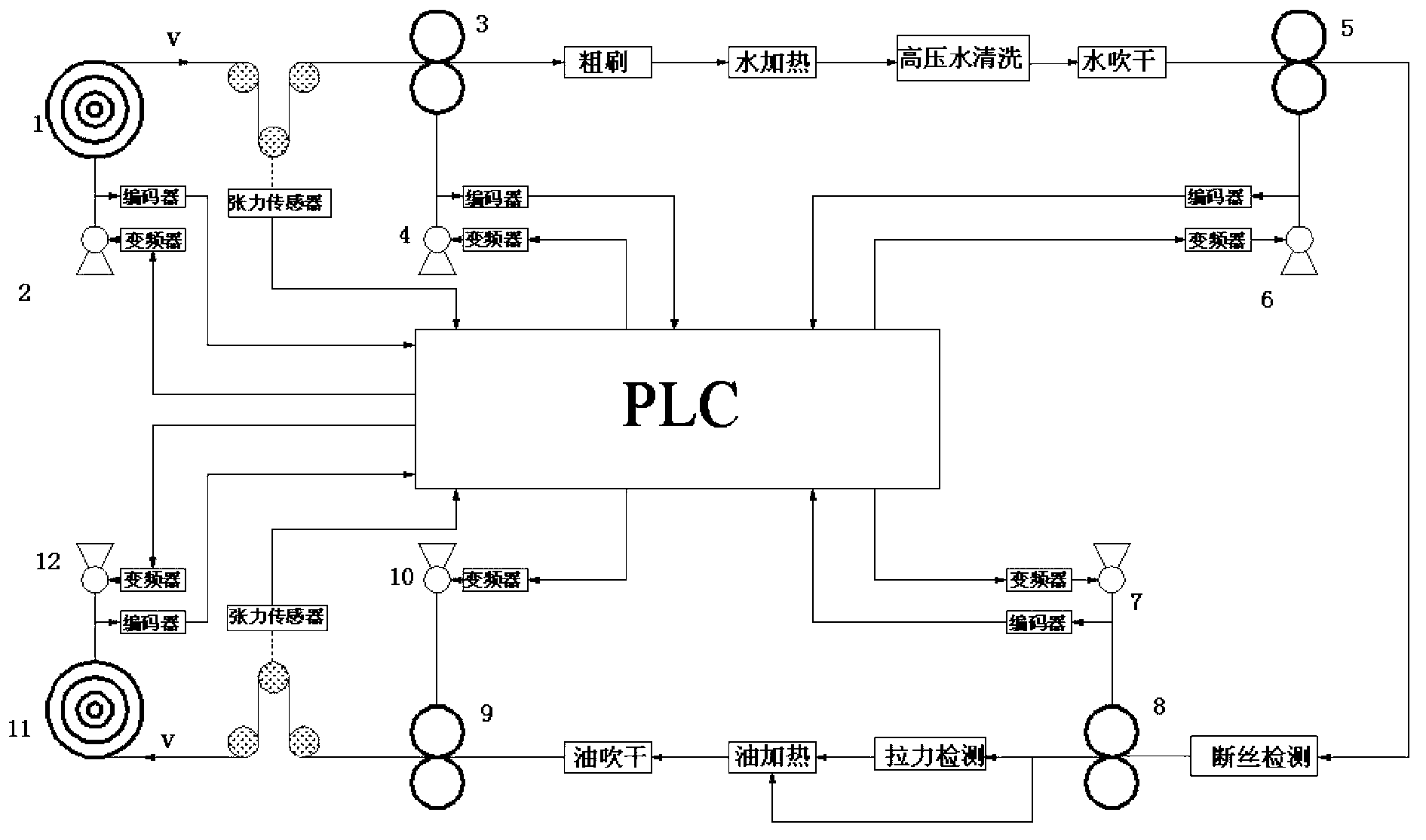

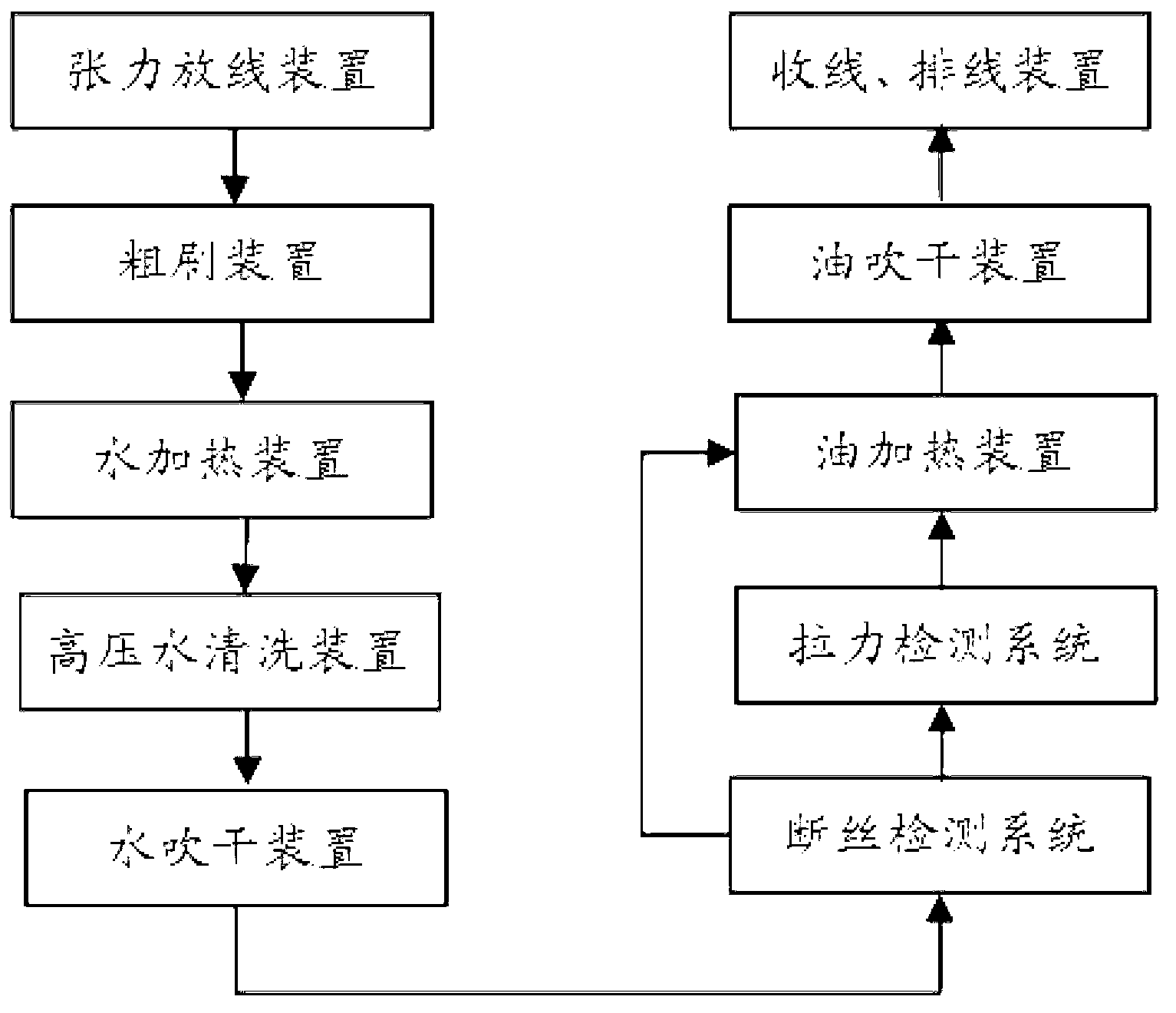

[0043] Such as figure 2shown. According to the technological process of the traction wire rope maintenance line, automatic continuous maintenance is the main feature of the traction wire rope maintenance line control system production. The length of the steel wire rope maintenance line is relatively long. In order to carry out continuous maintenance and testing of the steel wire rope and perform segmental control, each processing unit is driven by an independent motor. Divided into constant line speed control and constant tension control. When there is a difference in speed between the units, it can adjust its own speed in time and automatically keep it consistent with the adjacent units.

[0044] The multi-unit synchronous control system of the traction wire rope maintenance line includes a pay-off tension control system, a coarse brush traction speed control system, a water dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com