A method for treating alkaline gold extraction tailings with acid production tail gas

A technology for making acid tail gas and tailings, which is applied in the direction of chemical instruments and methods, non-metallic elements, and improvement of process efficiency. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

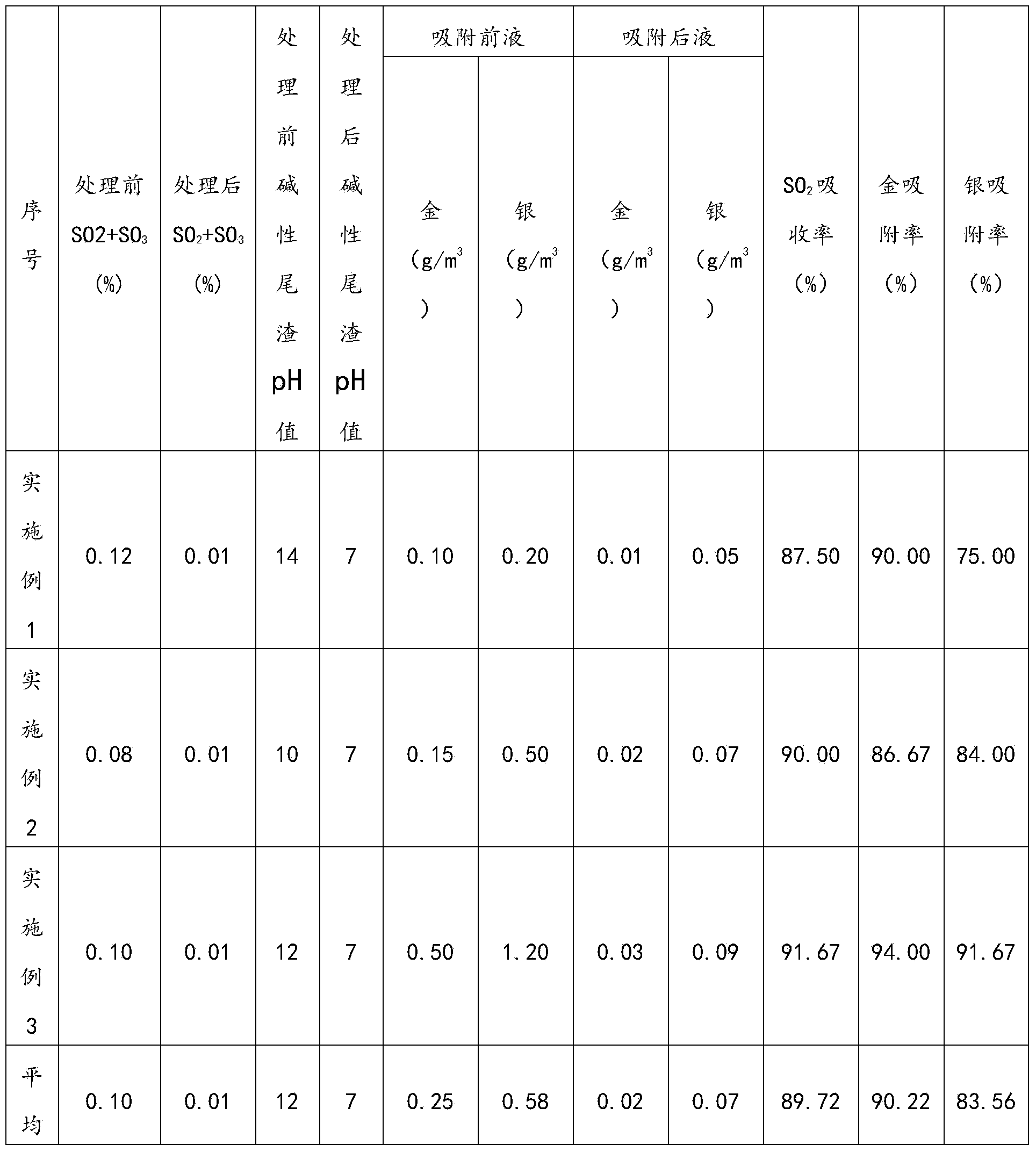

Examples

Embodiment 1

[0028] A method for treating alkaline gold extraction tailings by using tail gas from acid production, comprising the following steps:

[0029] 1) Analyzing the content of elements such as sulfur, arsenic, and carbon in the minerals, configuring gold concentrate containing 15% sulfur, 5% arsenic, and 1% carbon, and then adding water to stir until uniform to obtain a pulp with a concentration of 60% (concentration is 60% ore pulp and refers to that the solid mineral weight is 60 grams in every 100 grams of ore pulp);

[0030] 2) Spray the 60% ore slurry obtained in step 1) into a roasting furnace, and roast at a high temperature of 600° C. to obtain roasting flue gas and calcined sand after roasting. The roasting flue gas is discharged from the roasting furnace Then it enters the first-level cooling dust collector and the second-level cooling dust collector in turn. The roasting flue gas in the first-level cooling dust collector and the dust-laden flue gas in the second-level c...

Embodiment 2

[0037] A method for treating alkaline gold extraction tailings by using tail gas from acid production, comprising the following steps:

[0038] 1) Analyzing the content of sulfur, arsenic, carbon and other elements in the minerals, configuring gold concentrate containing 25% sulfur, 1% arsenic, and 1% carbon, and then adding water to stir until uniform to obtain a pulp with a concentration of 65% (Concentration is 65% ore pulp and refers to that the solid mineral weight is 65 grams in every 100 grams of ore pulp);

[0039] 2) Spray the 65% ore slurry obtained in step 1) into a roasting furnace, and roast at a high temperature of 650° C. to obtain roasting flue gas and calcined sand after roasting. The roasting flue gas is discharged from the roasting furnace Then it enters the first-level cooling dust collector and the second-level cooling dust collector in turn. The roasting flue gas in the first-level cooling dust collector and the dust-laden flue gas in the second-level coo...

Embodiment 3

[0046] A method for treating alkaline gold extraction tailings by using tail gas from acid production, comprising the following steps:

[0047] 1) configure the gold concentrate containing 20% sulfur, 10% arsenic, and 5% carbon, then add water and stir until uniform to obtain a 70% pulp; The amount of solid minerals contained in the pulp is 70 grams);

[0048] 2) Spray the 70% ore slurry obtained in step 1) into a roasting furnace, and roast at a high temperature of 700° C. to obtain roasting flue gas and calcined sand after roasting. The roasting flue gas is discharged from the roasting furnace Then it enters the first-level cooling dust collector and the second-level cooling dust collector in turn. The roasting flue gas in the first-level cooling dust collector and the dust-laden flue gas in the second-level cooling dust collector pass through a flue gas When the cooling device is rapidly cooled, the gaseous arsenic in the roasting flue gas and dusty flue gas will directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com