An aluminum electrolytic cell that slows down melt fluctuation and resists erosion

An aluminum electrolytic cell and anti-scouring technology, which is applied in the field of aluminum electrolytic cells, can solve problems such as the weakening of the dynamic self-regulation ability and protection function of the side of the tank, the difficulty in maintaining a stable and ideal shape of the side of the tank, and the difficulty in efficient and stable production of the electrolytic cell. No impact on electrolysis cost, prolong life and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

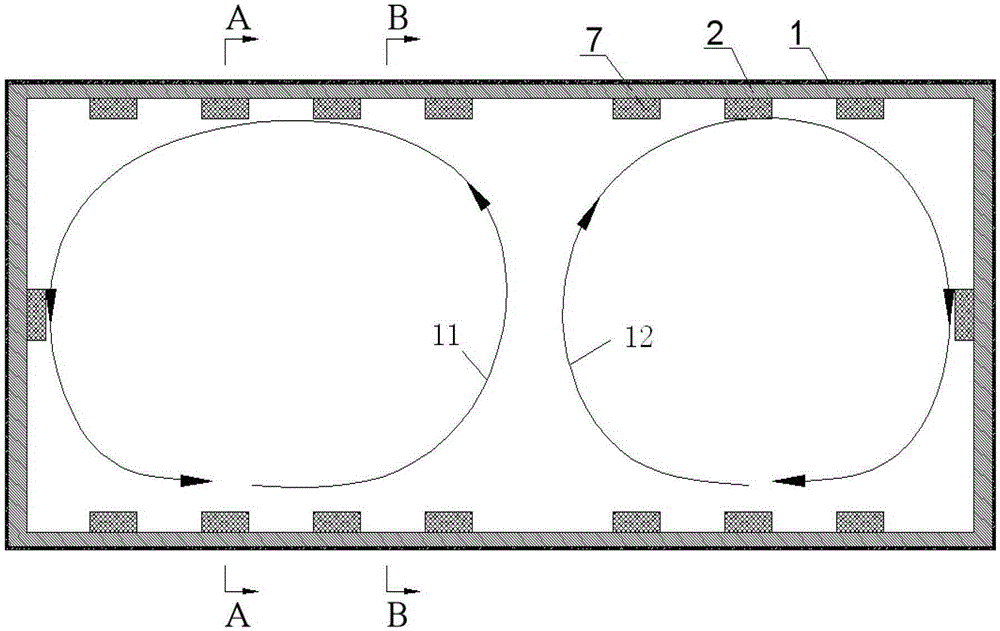

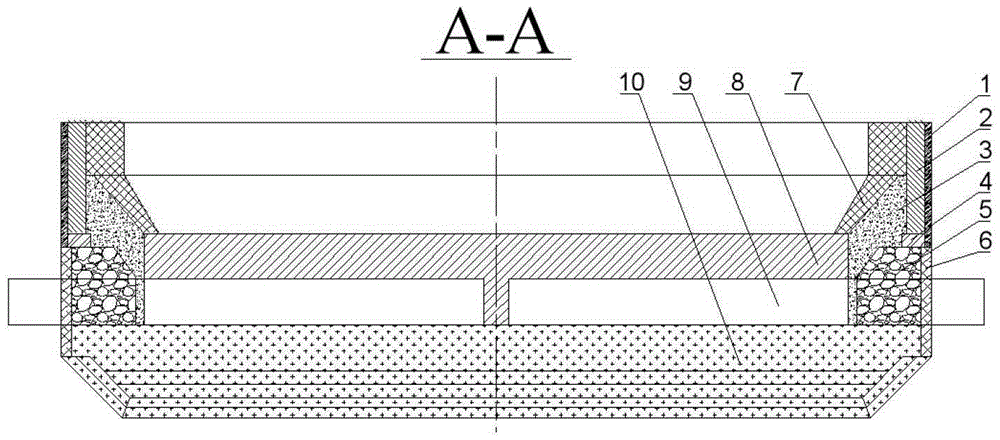

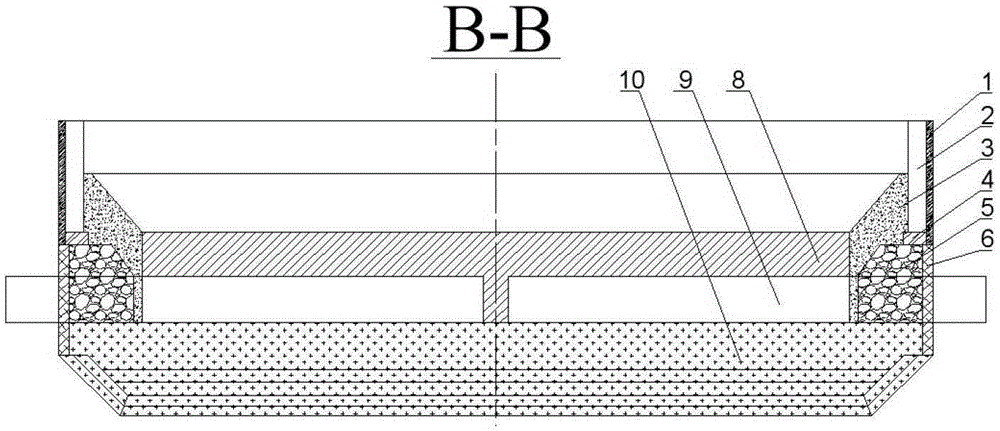

[0031] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the electrolytic cell liner with rectangular artificial anti-wave tank sides of the present invention is composed of dry anti-seepage material 1, common side carbon block 2, tamping paste 3, high alumina brick 4, high-strength castable material 5, Calcium silicate board 6, artificial wave-proof tank side 7, cathode steel rod 8, cathode carbon block 9 and bottom lining 10, and several raised artificial wave-proof tank sides 7 are arranged on the aluminum electrolytic cell according to the flow rule of the melt On the side of the inner liner, the artificial anti-wave groove side 7 and the electrolytic cell lining jointly build a liner structure similar to the anti-wave lift. Wherein, the artificial anti-wave tank side 7 is installed on the side of the electrolyzer (such as figure 2 and image 3 As shown), the installation position is determined according to the flow field characteristics of the electrol...

Embodiment 2

[0033] Such as figure 2 , image 3 and Figure 5 As shown, the electrolytic cell liner with trapezoidal artificial anti-wave tank side of the present invention is composed of dry anti-seepage material 1, common side carbon block 2, tamping paste 3, high alumina brick 4, high-strength castable material 5, Calcium silicate board 6, artificial wave-proof tank side 7, cathode steel rod 8, cathode carbon block 9 and bottom lining 10, and several raised artificial wave-proof tank sides 7 are arranged on the aluminum electrolytic cell according to the flow rule of the melt Lined sides. In this embodiment, except that the horizontal appearance shape of the artificial anti-wave groove side 7 is changed into a trapezoid (such as Figure 5 Shown), others are consistent with embodiment 1. The vertical cross-sectional shape of the artificial anti-wave groove side 7 of the present embodiment is still figure 2 and image 3In the section shown, the upper and lower sides of the horizon...

Embodiment 3

[0035] Such as figure 2 , image 3 , Figure 6 and Figure 7 As shown, the electrolytic cell lining with "T" shaped artificial anti-wave tank side of the present invention is composed of dry anti-seepage material 1, ordinary side carbon block 2, tamping paste 3, high alumina brick 4, high-strength cast Material 5, calcium silicate board 6, artificial wave-proof groove side 7, cathode steel rod 8, cathode carbon block 9 and bottom lining 10, and several raised artificial wave-proof groove sides 7 are arranged on the aluminum The side of the liner of the electrolytic cell. In this embodiment, except that the horizontal appearance shape of the artificial anti-wave groove side 7 is changed to a "T" shape (such as Figure 6 Shown), others are consistent with embodiment 1. Wherein, the horizontal length dimensions L1 and L2 of the artificial anti-wave groove side 7 are 10cm-30cm and 20cm-50cm respectively, and H1 and H2 are 20cm-30cm and 5cm-15cm respectively. This embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com