A kind of 3D sound-absorbing body and preparation method thereof

A 3D, polyester staple fiber technology, used in sound insulation, textiles and papermaking, building components, etc., can solve the problems of sound absorption effect, troublesome installation of sound absorption body, complicated production process, etc. Good sound effect, easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

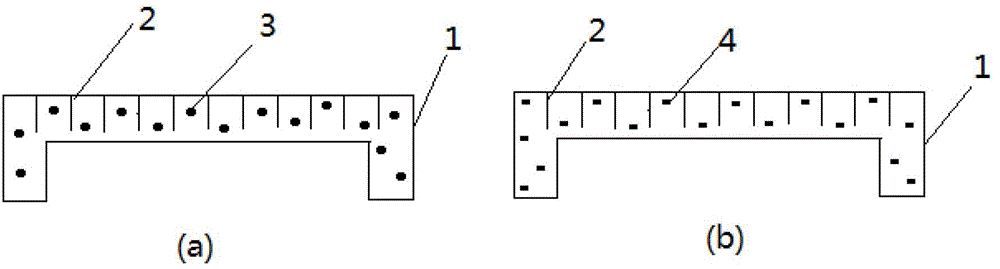

[0029] Such as figure 1 The 3D sound-absorbing body shown includes a first polyester staple fiber layer, the first polyester staple fiber and the second polyester staple fiber are evenly distributed in the first polyester staple fiber layer, and the melting point of the first polyester staple fiber is 180°C; the melting point of the second polyester staple fiber is 255°C. The thickness of the first polyester staple fiber layer is 4mm; the 3D sound-absorbing body is an open cuboid structure with a length and width of 700mm and a height of 40mm.

[0030] The mass ratio of the second polyester staple fiber to the first polyester staple fiber is 1:1.

[0031] Needle-punched holes are evenly distributed on the surface of the first polyester staple fiber layer, the aperture of the needle-punched hole is 1.8 mm, the depth of needle-punched is three-quarters of the thickness of the first polyester staple fiber layer, and the needle-punched density is 1.0 needles / cm 2 .

[0032] T...

Embodiment 2

[0040] The 3D sound-absorbing body includes a first polyester staple fiber layer, the first polyester staple fiber and the second polyester staple fiber are evenly distributed in the first polyester staple fiber layer, and the melting point of the first polyester staple fiber is 160°C; The melting point of the second polyester staple fiber was 258°C. The thickness of the first polyester staple fiber layer is 8mm; the 3D sound-absorbing body is an open cuboid structure with a length and width of 800mm and a height of 80mm.

[0041] The mass ratio of the second polyester staple fiber to the first polyester staple fiber is 1:1.5.

[0042] Needle-punched holes are evenly distributed on the surface of the first polyester staple fiber layer, the aperture of the needle-punched hole is 1.5 mm, the depth of needle-punched is 4 / 5 of the thickness of the first polyester staple fiber layer, and the needle-punched density is 1.2 needles / cm 2 .

[0043] The preparation method of the abo...

Embodiment 3

[0051] The 3D sound-absorbing body includes a first polyester staple fiber layer, the first polyester staple fiber and the second polyester staple fiber are evenly distributed in the first polyester staple fiber layer, and the melting point of the first polyester staple fiber is 180°C; The melting point of the second polyester staple fibers was 260°C. The thickness of the first polyester staple fiber layer is 8mm; the 3D sound-absorbing body is an open cuboid structure with a length and width of 900mm and a height of 80mm.

[0052] The mass ratio of the second polyester staple fiber to the first polyester staple fiber is 1:2.3.

[0053]Needle-punched holes are evenly distributed on the surface of the first polyester staple fiber layer, the aperture of the needle-punched hole is 1.5 mm, the depth of needle-punched is 4 / 5 of the thickness of the first polyester staple fiber layer, and the needle-punched density is 1.1 needles / cm 2 .

[0054] The preparation method of the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com