A large thickness blunt trailing edge airfoil blade of a large wind turbine

A technology of airfoil blades and large thickness, which is applied in wind turbines, wind turbine components, engines, etc. It can solve the problems of low wind energy utilization rate and heavy structure weight, and achieve the reduction of self-weight, increase of static stiffness, and improvement of blade structure efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

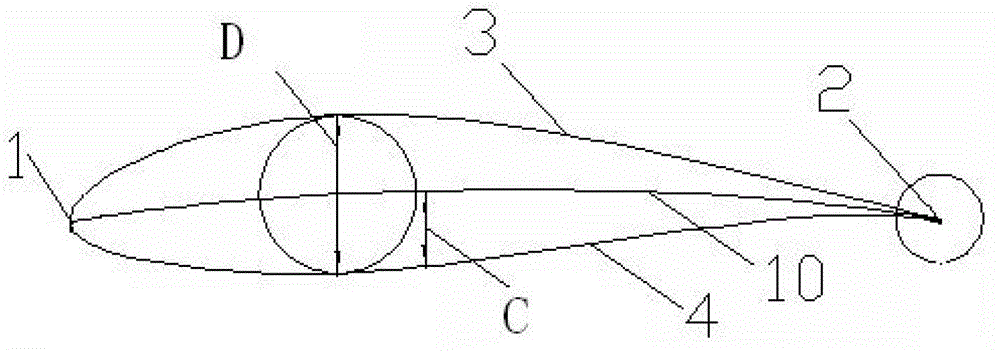

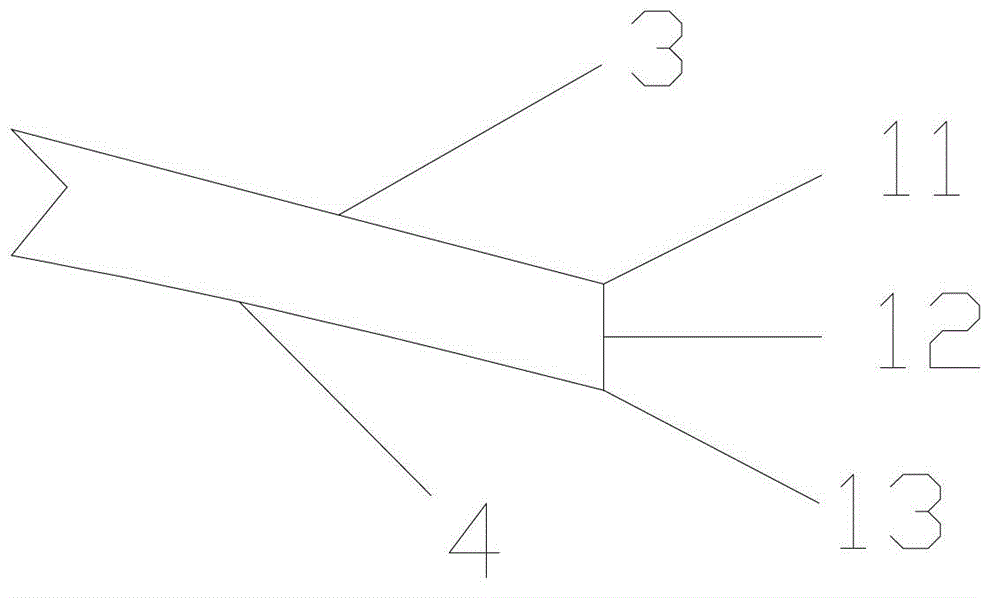

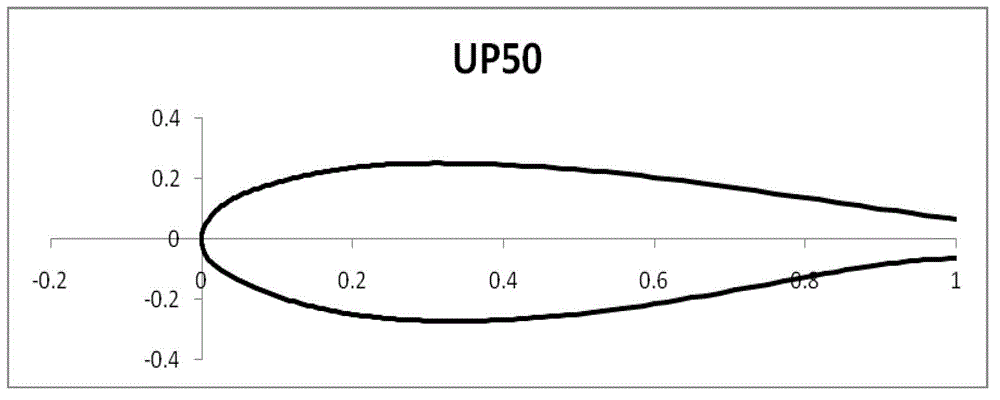

[0017] refer to figure 1 , figure 2 , the present invention provides a blade airfoil with a relative thickness of 50% (named UP50). The profile line 3 and the pressure surface profile line 4 are composed of the front edge 1 is a circular arc, the front edge 1 is respectively connected with the suction surface profile line 3 and the pressure surface profile line 4, the curvature at the connection point is continuous, and the end of the suction surface profile line 3 11 is connected with the end 13 of the pressure surface profile line 4 to form the trailing edge 2.

[0018] first of all, yes figure 1 The names of the various parts are defined as follows:

[0019] 1. Middle arc 10: Make a series of inscribed circles of suction surface profile 3 and pressure surface profile 4 in the airfoil, and the line connecting the centers of these inscribed circles is called the center arc 10 of the airfoil.

[0020] 2. Chord length: the connecting line between the front and rear ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com