Silicon carbide ceramic hook

A technology of silicon carbide ceramics and connecting seats, applied in the field of hooks, can solve problems such as difficulty in determining the position of cable hooks, waste of cables, easy rust or aging, etc., and achieve excellent chemical properties, easy to use, and not easy to rust and aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

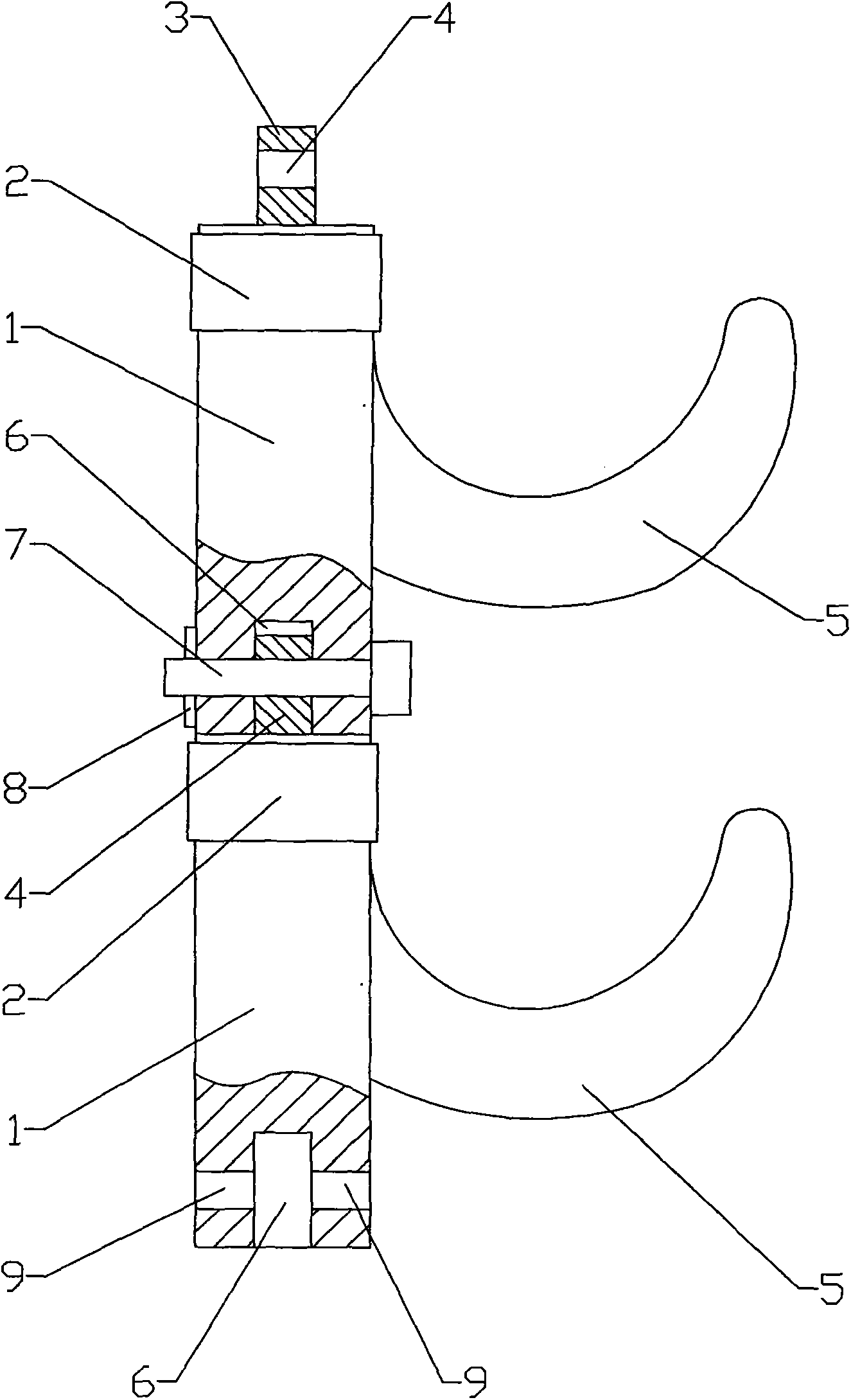

[0009] Example: as attached figure 1 As shown, a silicon carbide ceramic hook includes a connecting seat 1, one side of the connecting seat 1 is provided with a hook body 5 made of silicon carbide ceramics, and the upper end of the connecting seat 1 is provided with a connecting column 3, so The connecting column 3 is provided with a first through hole 4, the lower part of the connecting seat 1 is provided with a connecting hole 6, and the two sides of the connecting hole 6 are provided with a second through hole 9 matched with the first through hole 4. , the upper part of the connecting seat 1 is provided with a reflective tape 2 .

[0010] A connecting shaft 7 is arranged in the first through hole 4 and the second through hole 9 , and a cotter pin 8 is arranged on the connecting shaft 7 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap