Chain tensioner test bench

A tensioner and test bench technology, applied in the testing of machine/structural parts, instruments, and mechanical parts, etc., can solve the evaluation of chain tensioner performance, the lack of sufficient test data support, and the inability to improve technology. Obtain the test data and curves of the chain tensioner, and achieve the effect of good application value, complete functions, and good human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

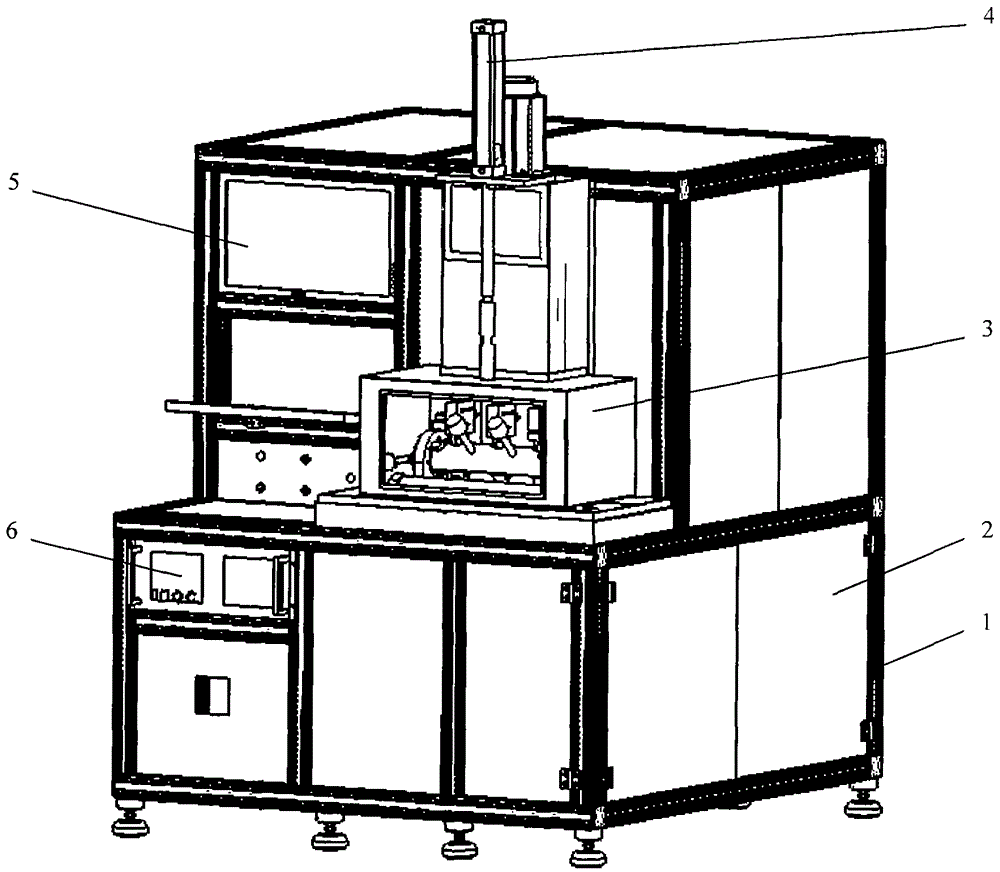

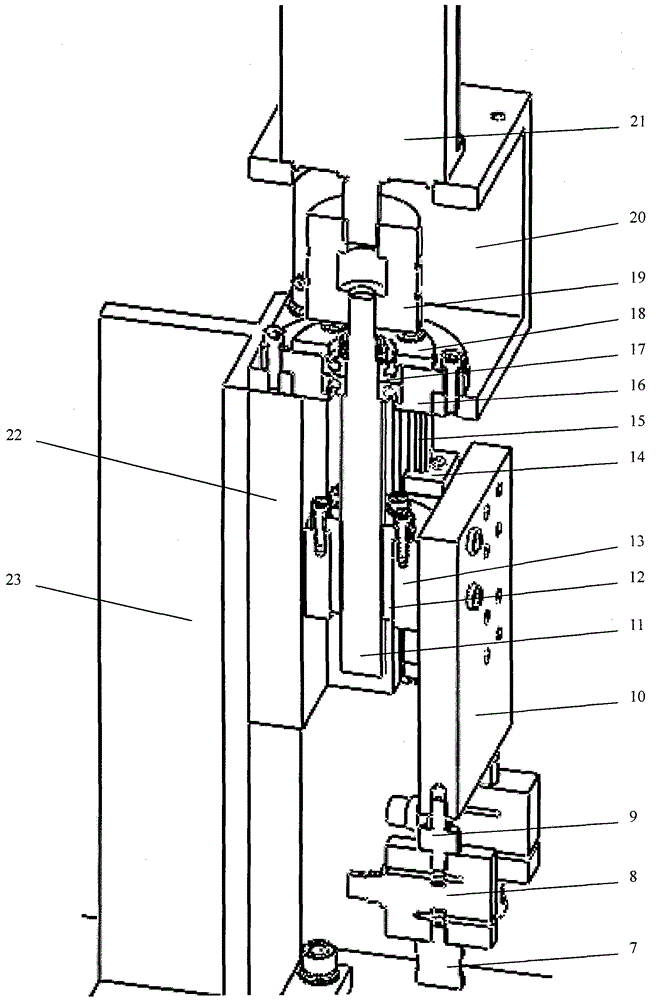

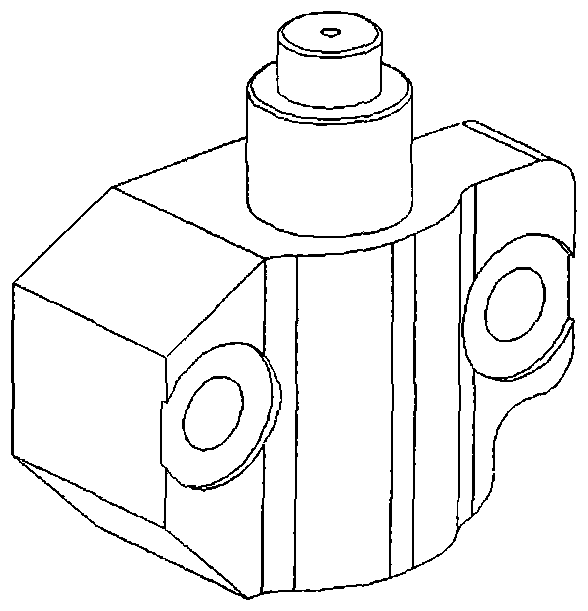

[0030]The chain tensioner test bench of the present invention is mainly composed of a bench, an oil retaining mechanism, an oil supply system, a driving and pressing mechanism, a tensioner supporting mechanism, a tensioner clamping mechanism, and a computer control system; the oil retaining mechanism, the oil supply The oil system, the drive-down mechanism, the tensioner support mechanism, the tensioner clamping mechanism, and the computer control system are all installed and fixed on the stand.

[0031] see figure 1 , The bench adopts industrial aluminum profile frame 1, and for the beauty and dustproof of the test bench, a stainless steel plate 2 is installed on the surface of the test bench.

[0032] see figure 1 , Oil retaining mechanism mainly is made up of oil retaining cylinder 4, oil retaining cover 3, and oil retaining cylinder 4 is fixed on the stand, and oil retaining cover 3 is fixed on the oil retaining cylinder 4 piston rods. During the test, the piston rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com