A liquid heavy metal cooling reactor fuel assembly

A liquid heavy metal and fuel assembly technology, applied in the field of nuclear engineering, can solve the problems of high processing difficulty and high accident risk, and achieve the effect of inherent safety and risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

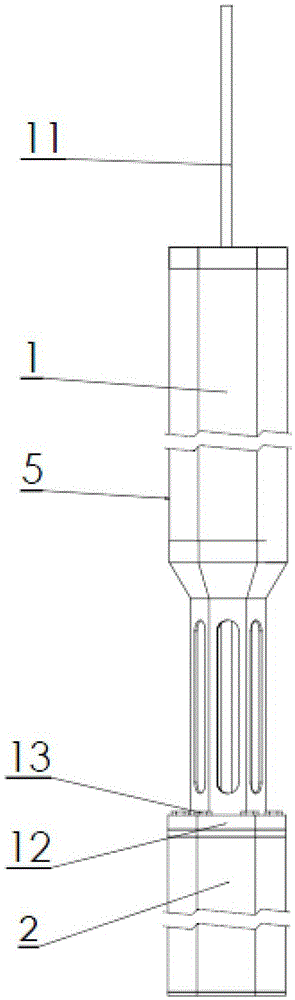

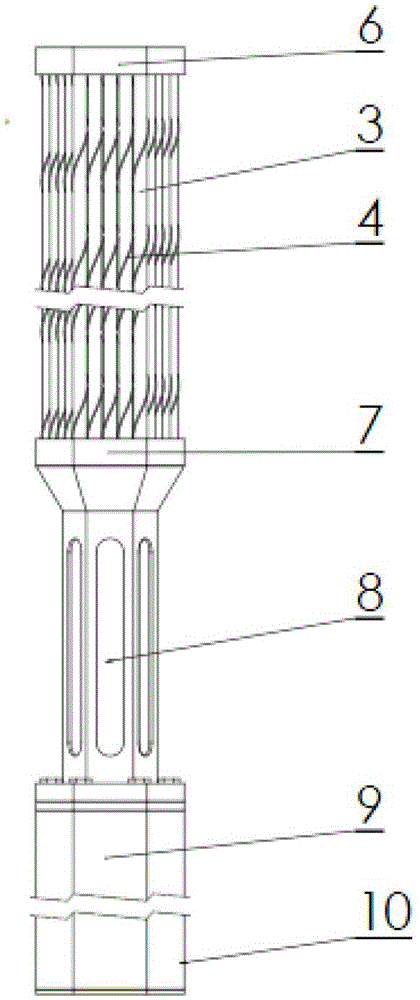

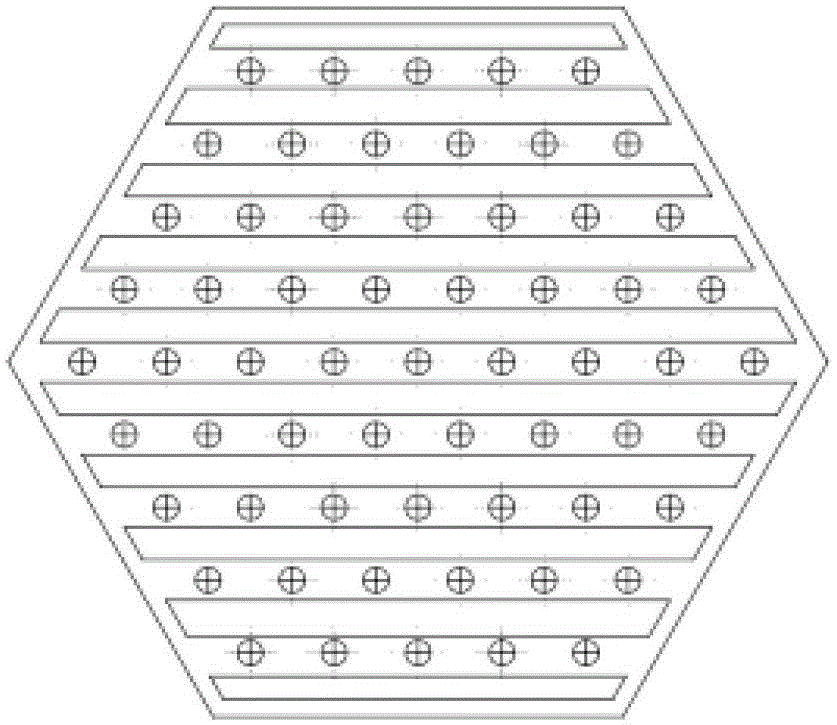

[0019] Attached below Figure 1-3 A kind of liquid lead-based alloy cooling fast neutron reactor fuel assembly proposed by the present invention is further introduced:

[0020] Such as figure 1 , 2 , 3, after the upper tube base 6 and the combustion outer sleeve 5 are welded together, the upper end plugs of the bundled fuel elements 3 are inserted into the apertures of the upper tube base 6 to fix. The bundled fuel elements 3 are fixed with metal winding wires 4, and then the lower end plugs of the bundled fuel elements 3 are inserted into the small holes of the lower tube base 7 to fix them. After installation, the lower tube base 7 and the combustion outer sleeve 5 are also welded together. Adjust the position of the hexagon of the coolant inlet 8 so that it coincides with the hexagon of the combustion outer sleeve 5 before welding. Insert the central bearing rod 11 into the center of the combustion system 1, which is part of the counterweight system 2, with an external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com