A kind of electric meter automatic assembly line and assembly method

An assembly line and electric meter technology, applied in measuring devices, measuring electrical variables, electrical program control, etc., can solve problems such as unguaranteed yield, easily damaged assembled products, poor environmental adaptability, etc., to achieve high efficiency, The effect of good production flexibility and flexible efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

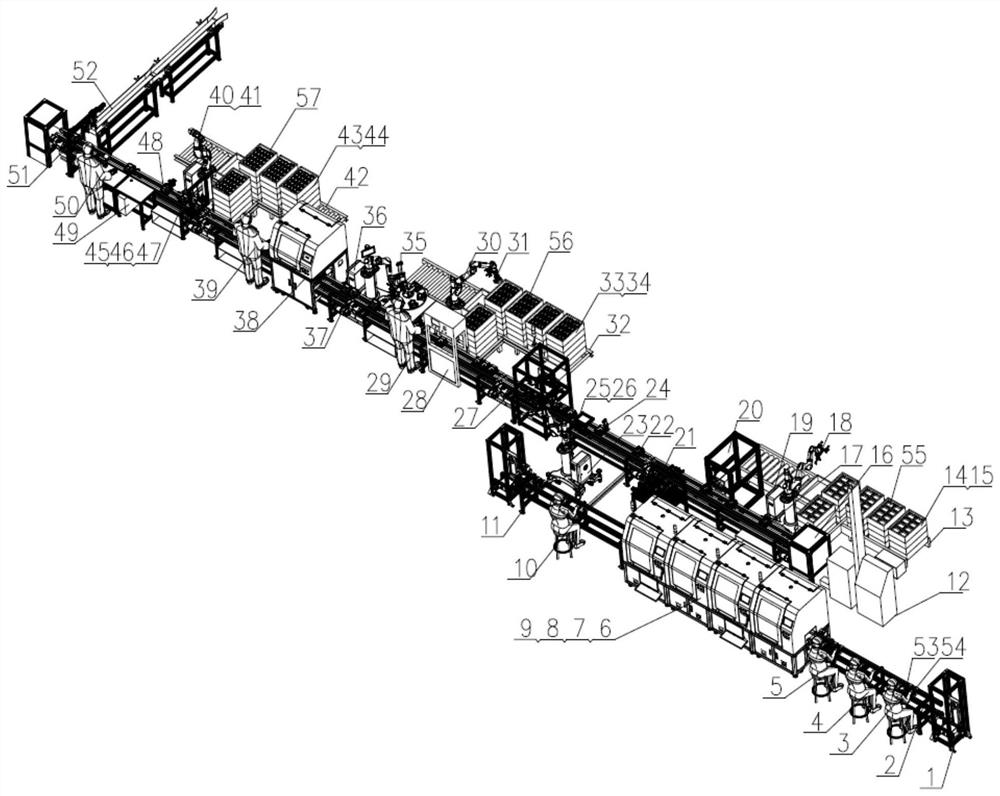

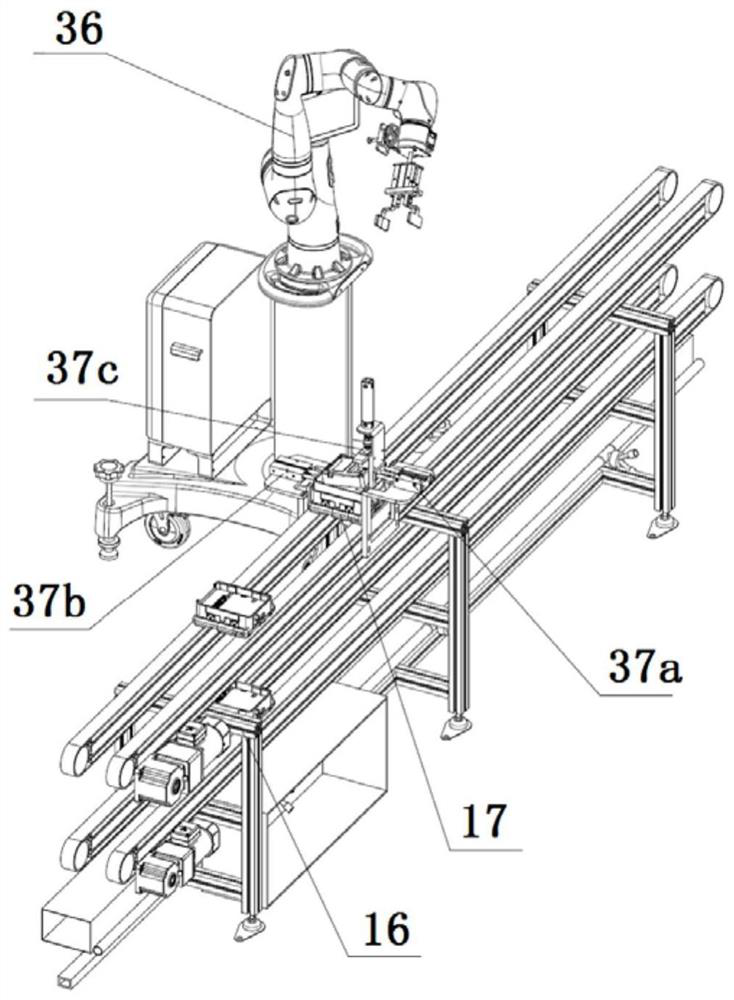

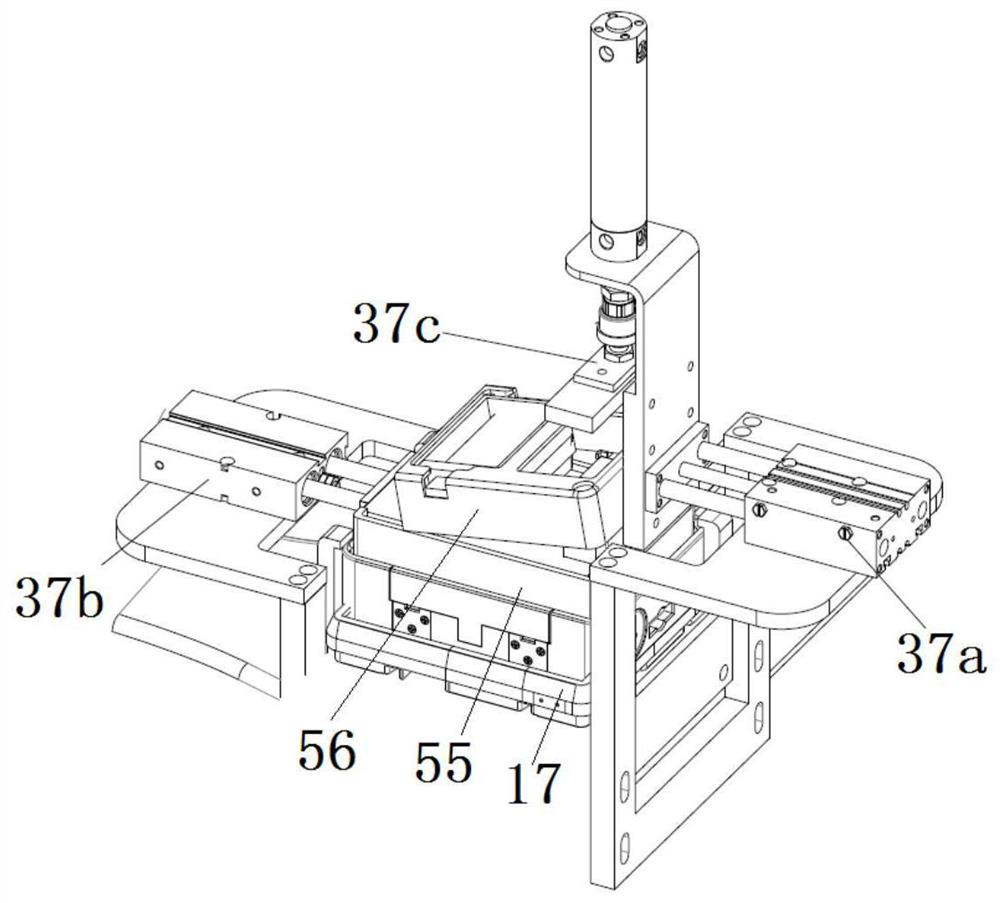

[0052] A meter automatic assembly line, such as figure 1 As shown, it is mainly composed of a welding line and an electric meter assembly line, and the cross-line is connected by an intelligent collaborative robot 23 . The welding line is composed of single-head welding machine 6, single-head welding machine 7, single-head welding machine 8 and double-head welding machine 9, and two front and rear synchronous conveying systems (welding carrier elevator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com