Method and device for recycling metal in waste lithium ion batteries by water-soluble ionic liquid

A technology of lithium-ion batteries and ionic liquids, which is applied in the field of water-soluble ionic liquids to recycle metals in waste lithium-ion batteries, can solve problems such as retention, no complete set of commercial operation processes, and weak research on recycling processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

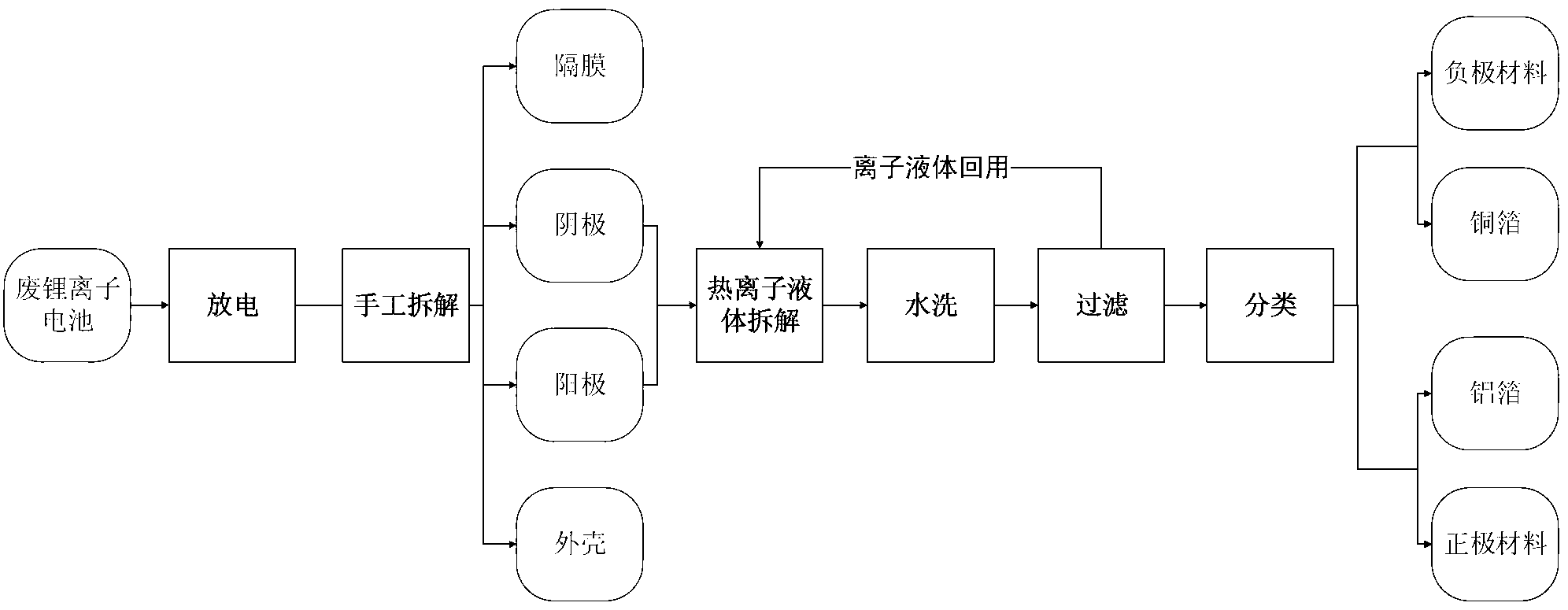

[0023] Such as figure 1 Shown, a kind of water-soluble ionic liquid of the present invention reclaims the method for metal in the waste lithium ion battery, comprises the steps:

[0024] Step 1: Put the spent lithium-ion battery in salt water for discharge treatment, and then dry it;

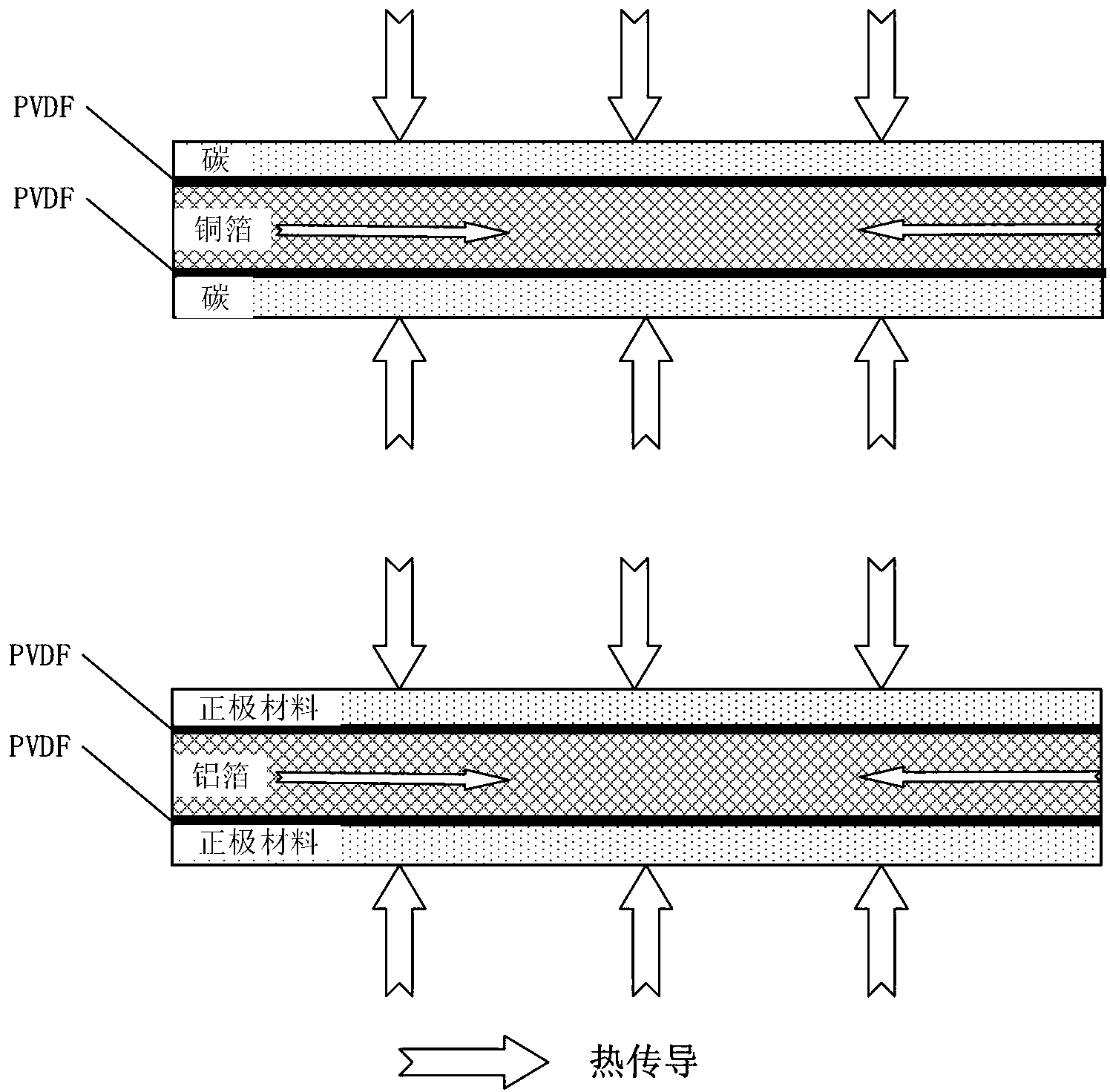

[0025] Step 2: Manually disassemble and separate the discharged waste lithium-ion battery to obtain the anode, cathode, diaphragm and the shell containing the circuit board, and separate and classify them. The anode is copper foil and negative electrode material carbon, and the cathode is aluminum foil and Cathode material;

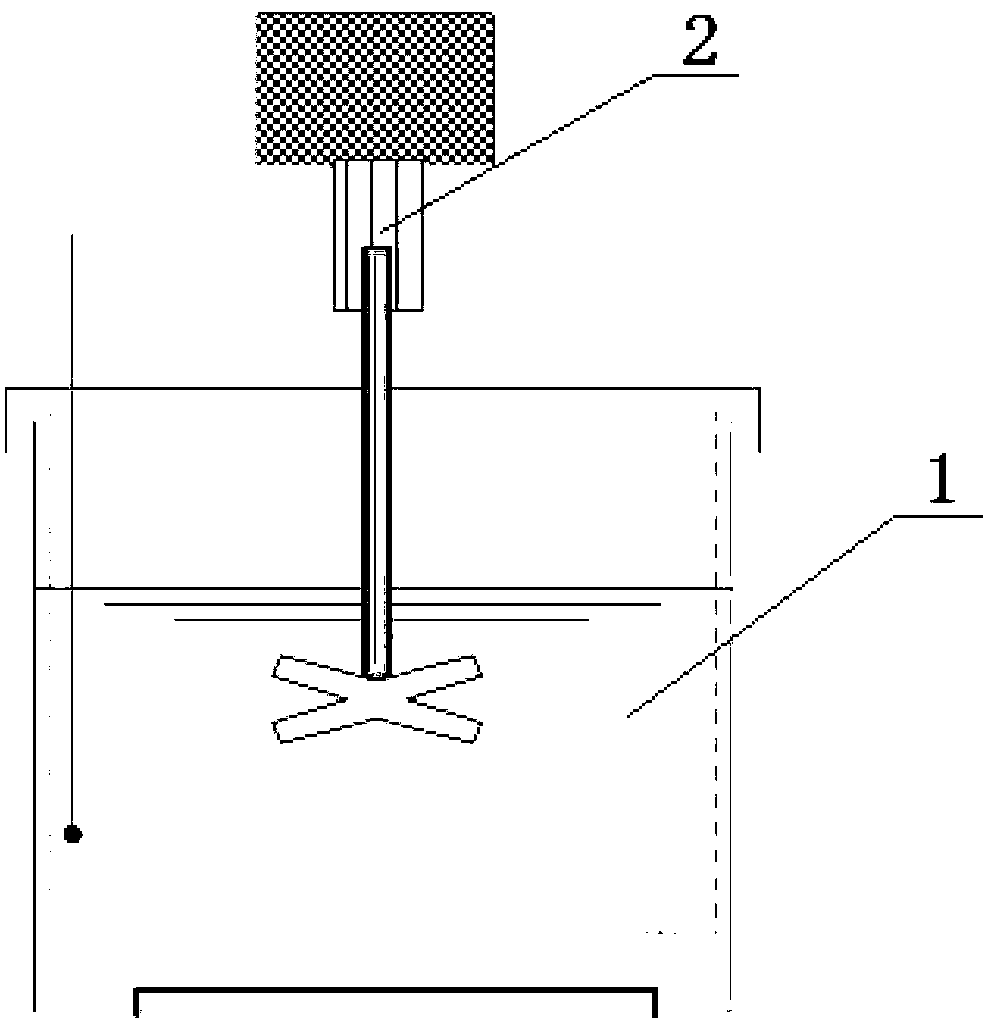

[0026] Step 3: Put [BMIm]BF 4 The ionic liquid was placed in an oil bath, heated to 175°C, and stirred with an electric mixer, and the speed of the electric mixer was controlled at 300rpm;

[0027] Step 4: Add the anode and cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com