Flat vibration motor

A technology of flat vibrating motors and magnets, which is applied in the direction of electric components, mechanical energy control, electrical components, etc. It can solve the problems of slow motor feedback to signals, affecting the service life of the motor, and poor user experience, so as to achieve fast startup and easy assembly. , The effect of signal feedback sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

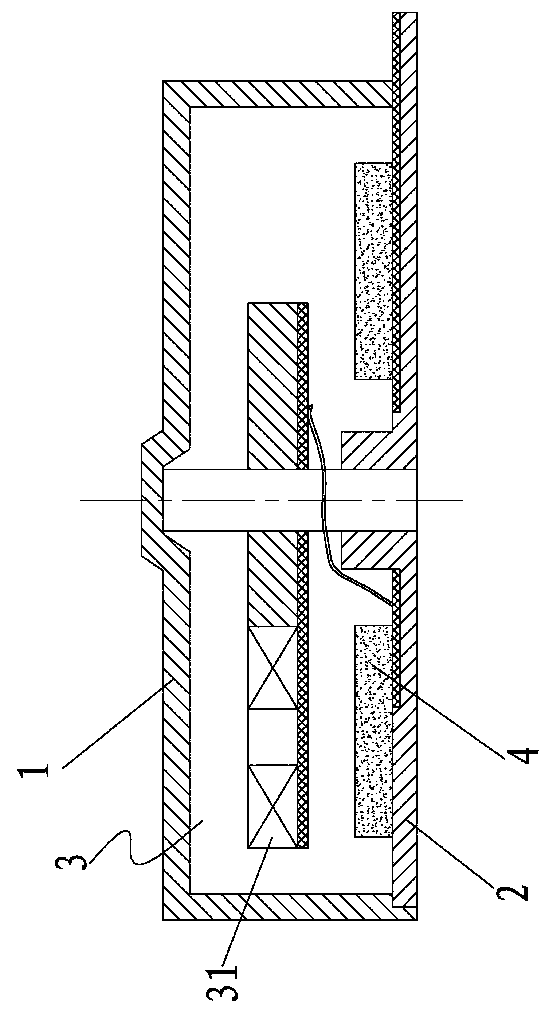

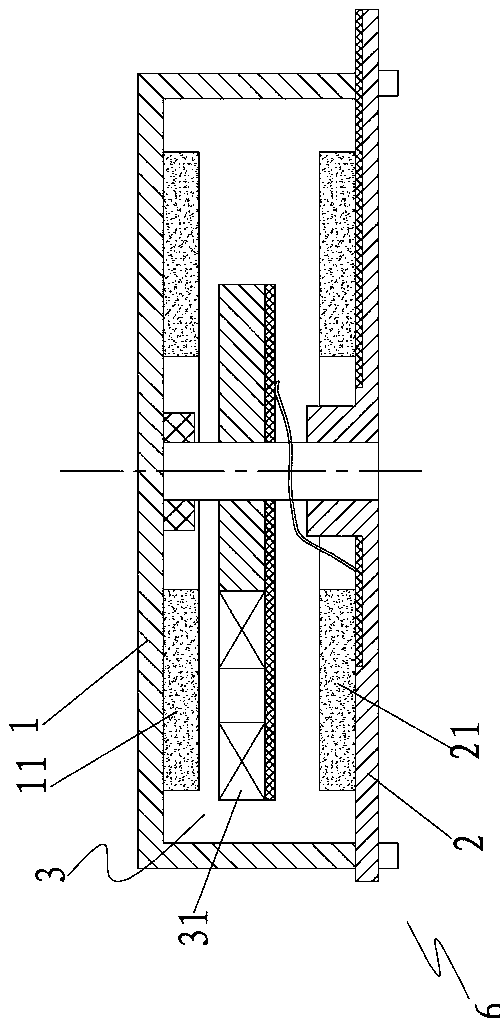

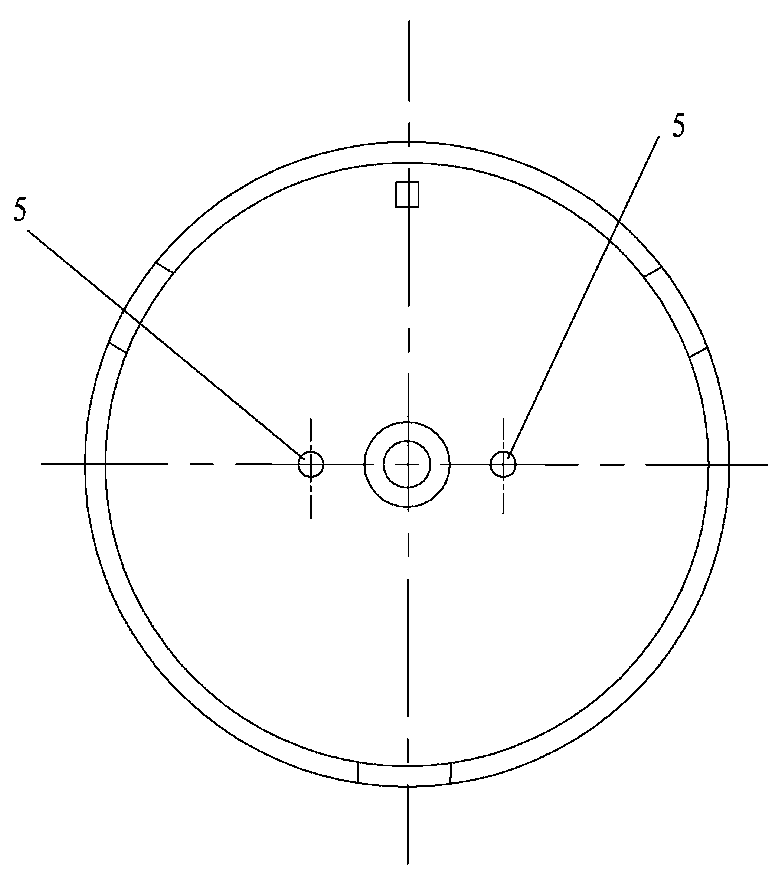

[0029] Details are attached Figure 2-5 shown. The flat vibration motor disclosed in this embodiment also includes an upper shell 1, a lower shell 2, and an eccentric rotor 3 installed in the cavity formed by the upper shell 1 and the lower shell 2. The eccentric rotor 3 is provided with two coils 31 and The counterweight plate, the two coils 31 and the counterweight plate are located in the same semicircle arc of the eccentric rotor 3. When the eccentric rotor 3 rotates, since the center of gravity is not at the center of rotation, vibrations are generated. One of the biggest differences between this scheme and the existing flat vibration motor is that there are many pairs of upper magnets 11 and lower magnets 21 symmetrically arranged on the inner wall of the upper shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com