Coating material containing organic/inorganic composite, organic/inorganic composite film and antireflection member

An inorganic composite film and inorganic composite technology, which can be used in the treatment of dyed organosilicon compounds, dyed polymer organic compounds, and inorganic pigments, etc., and can solve the problems of low productivity and inappropriate mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0750] [Example 1: 20nmSiO 2 -g-p(TFEMA-co-PFPMA), thermoplastic]

[0751] According to the ratio in Table 1, the organic-inorganic composite A was produced according to the following steps. The concentration of each component is a numerical value based on the total amount of each component. The evaluation results of the obtained organic-inorganic composite A are listed in Table 6.

[0752] (1) Add CuBr and CuBr to the Schlenk bottle with rotor 2 , carry out vacuum treatment on the inside of the flask and replace it with nitrogen. This operation is repeated 3 times. After deoxygenating the inside of the flask, a small amount of MIBK is introduced under nitrogen and stirred.

[0753] (2) Add PMDETA to the above solution, stir at 60° C., and use the obtained solution as a catalyst solution.

[0754] (3) BPS-modified 20-nm silica particles were put into another Schlenk bottle connected with a cooling tube and equipped with a rotor.

[0755] (4) Connect a cooling tube to the ...

Embodiment 2

[0776] [Example 2: 50nmSiO 2 -g-p(TFEMA / MMA / EA), thermoplastic]

[0777] Except having set the polymerization reaction conditions to 75 degreeC and 12 hours, the organic-inorganic composite B was manufactured by the method similar to Example 1 according to the compounding ratio of Table 1, and it evaluated. The evaluation results of the obtained organic-inorganic composite B are listed in Table 6. Since no chlorine was detected, the bromine content was expressed as the halogen content.

[0778] The number-average molecular weight (Mn) and mass-average molecular weight (Mw) of the polymer constituting the organic-inorganic composite B were measured by the above-mentioned method, and the results were Mn=14,200, Mw=21,900, and Mw / Mn=1.54. Polymer chains of uniform chain length are bound to the particles.

[0779] Using the organic-inorganic composite B, the solvent was changed to MIBK, and a coating material and an organic-inorganic composite film (coating film) were obtained ...

Embodiment 3

[0780] [Example 3: 50nm hollow SiO 2 -g-p(TFEMA-co-HEMA), thermoplastic]

[0781] Except having set the polymerization reaction conditions to 60 degreeC and 20 minutes, organic-inorganic composite C was manufactured by the method similar to Example 1 according to the composition of Table 1, and it evaluated. The evaluation results of the obtained organic-inorganic composite C are listed in Table 6. Since no chlorine was detected, the bromine content was expressed as the halogen content.

[0782] The organic-inorganic composite C was used, and a solvent in which MIBK and MEK were mixed at a ratio of 1:1 (volume ratio) was prepared by the above-mentioned method to obtain a coating material. At this time, ultrasonic treatment was performed for 3 hours. Furthermore, the coating film was produced by the method mentioned above. The evaluation results are listed in Table 9.

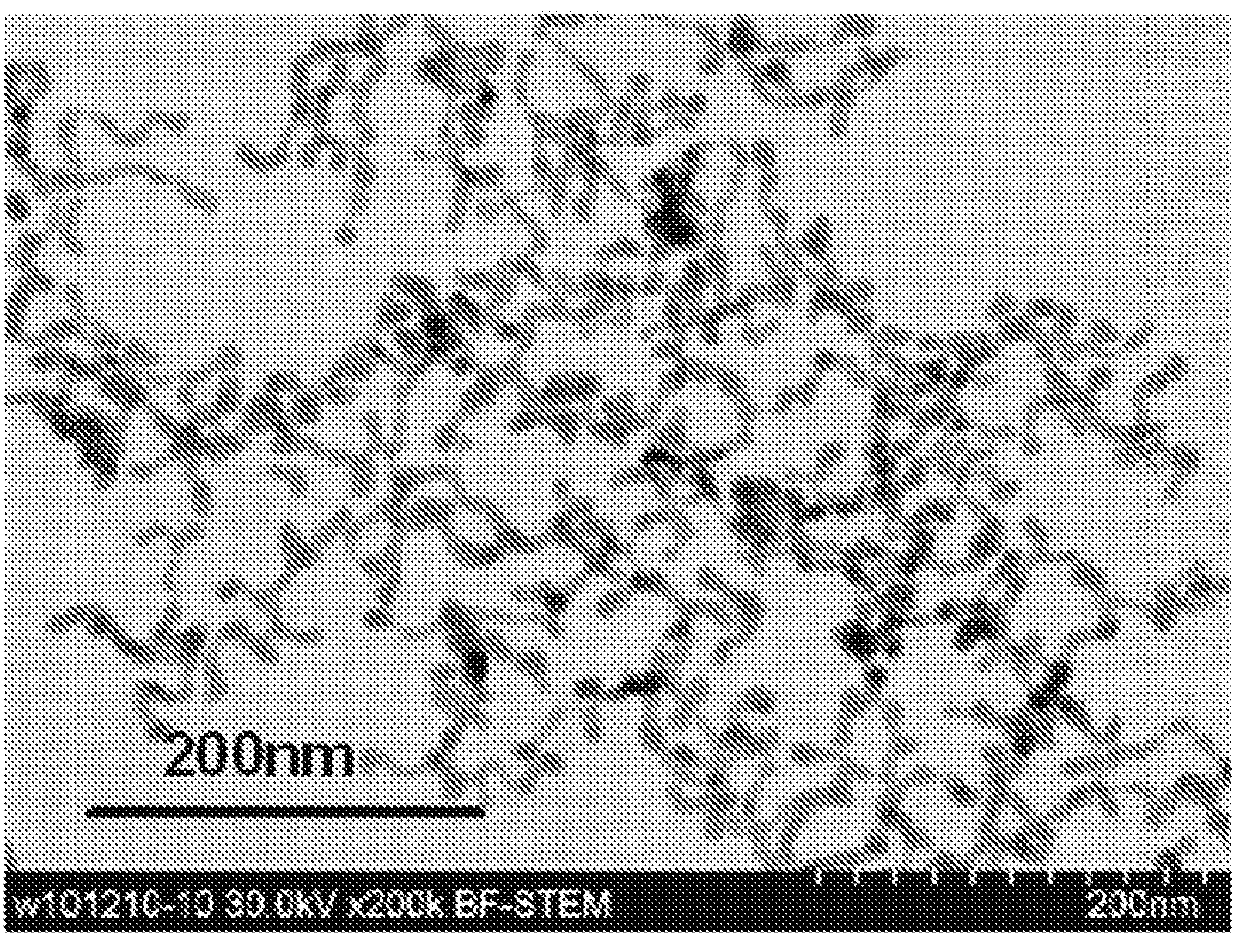

[0783] The external appearance was visually confirmed, and the aggregation of particles was not seen, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

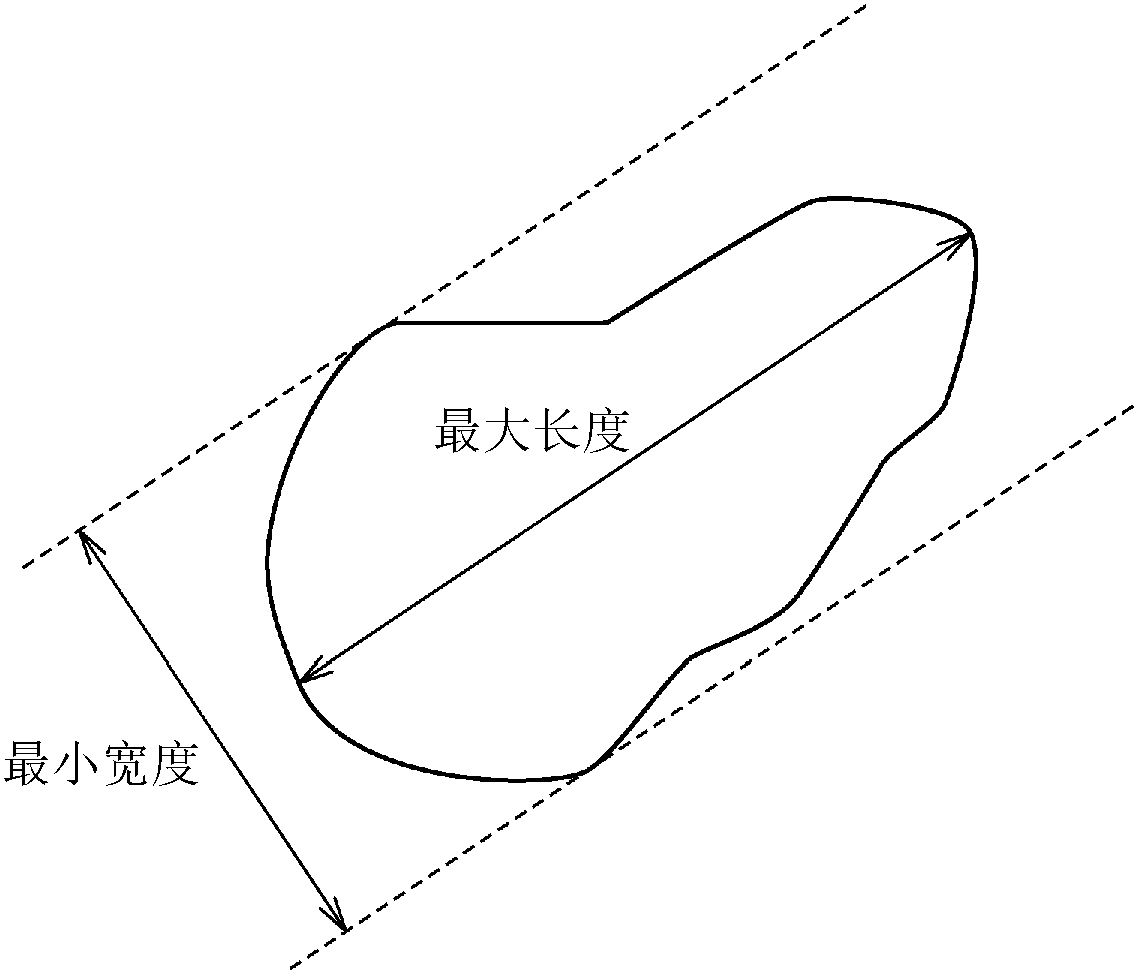

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com