Oyster mushroom cultivation method

A cultivation method and technology for oyster mushrooms, applied in the fields of botanical equipment and methods, horticulture, application, etc., can solve the problems of pollution, harm the environment, affect the nutritional value of oyster mushrooms, etc., and achieve the solution of environmental pollution, damage, fruiting transformation rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

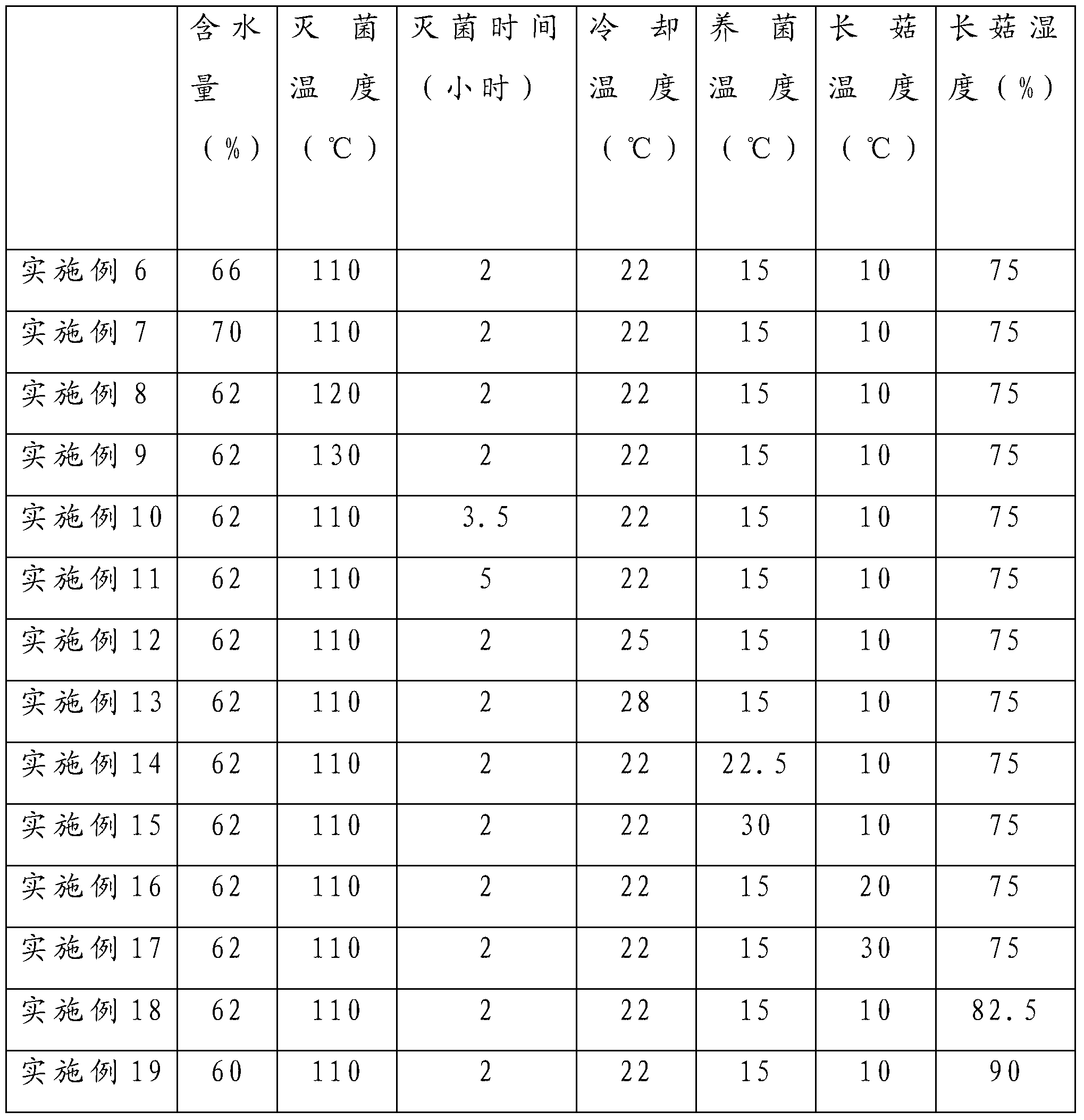

Examples

Embodiment 1

[0019] A cultivation method of oyster mushroom, comprising the following steps:

[0020] (1) Mixing material: Take 15% wood chips, 35% cottonseed hulls, 25% bran and 25% corn flour by weight and stir with water. When the water content reaches 62%, stop stirring.

[0021] (2) Packing: Put the above-mentioned mixed substances into mushroom bags for packing.

[0022] (3) Sterilization: Place the packaged bacteria bags in an environment with a temperature of 110°C for 2 hours to sterilize.

[0023] (4) Cooling: Cool the sterilized bacteria bag to 22°C.

[0024] (5) Inoculation: Inoculate the cooled bacteria bag.

[0025] (6) Bacteria cultivation: Place the inoculated bacteria bags in an environment with a temperature of 15°C to cultivate bacteria, and keep them dry and ventilated.

[0026] (7) Mushroom growth: After the hyphae are full, move to the greenhouse to grow mushrooms. The temperature in the greenhouse is 10°C, the humidity is 75%, and the light is dim.

Embodiment 2

[0028] A cultivation method of oyster mushroom, comprising the following steps:

[0029] (1) Mixing material: Take 25% wood chips, 35% cottonseed hulls, 20% bran and 20% corn flour according to the weight percentage, add water and stir, when the water content reaches 62%, stop stirring.

[0030] (2) Packing: Put the above-mentioned mixed substances into mushroom bags for packing.

[0031] (3) Sterilization: Place the packaged bacteria bags in an environment with a temperature of 110°C for 2 hours to sterilize.

[0032] (4) Cooling: Cool the sterilized bacteria bag to 22°C.

[0033] (5) Inoculation: Inoculate the cooled bacteria bag.

[0034] (6) Bacteria cultivation: Place the inoculated bacteria bags in an environment with a temperature of 15°C to cultivate bacteria, and keep them dry and ventilated.

[0035] (7) Mushroom growth: After the hyphae are full, move to the greenhouse to grow mushrooms. The temperature in the greenhouse is 10°C, the humidity is 75%, and the ligh...

Embodiment 3

[0037] A cultivation method of oyster mushroom, comprising the following steps:

[0038] (1) Mixing material: Take 35% wood chips, 35% cottonseed hulls, 15% bran and 15% corn flour according to the weight percentage, add water and stir, when the water content reaches 62%, stop stirring.

[0039] (2) Packing: Put the above-mentioned mixed substances into mushroom bags for packing.

[0040] (3) Sterilization: Place the packaged bacteria bags in an environment with a temperature of 110°C for 2 hours to sterilize.

[0041] (4) Cooling: Cool the sterilized bacteria bag to 22°C.

[0042] (5) Inoculation: Inoculate the cooled bacteria bag.

[0043] (6) Bacteria cultivation: Place the inoculated bacteria bags in an environment with a temperature of 15°C to cultivate bacteria, and keep them dry and ventilated.

[0044] (7) Mushroom growth: After the hyphae are full, move to the greenhouse to grow mushrooms. The temperature in the greenhouse is 10°C, the humidity is 75%, and the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com