Double-color injection molding knob cover, injection molding die and injection molding technology thereof

A technology of two-color injection molding and knobs, which is applied to household appliances, other household appliances, gears, etc., can solve the problems of cumbersome manufacturing process, high cost, fading, etc., and achieve the effect of simple manufacturing process, low cost and good production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

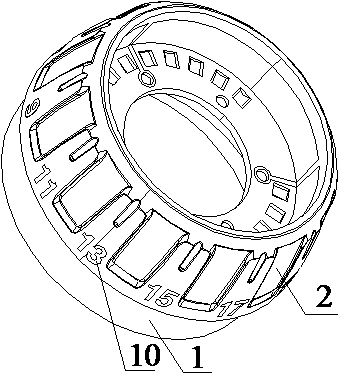

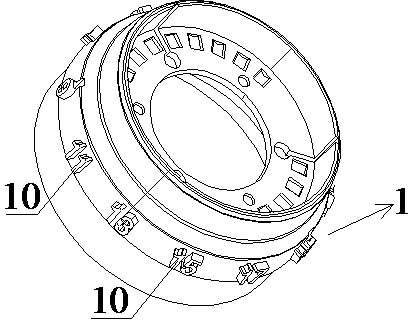

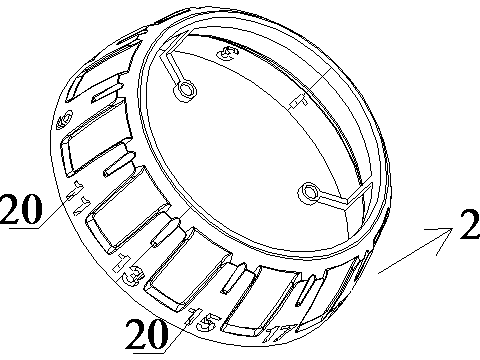

[0026] Embodiment 2: An injection mold for preparing the two-color injection knob cover of the above embodiment 1. The injection mold includes an inner mold of the knob cover and an outer mold of the knob cover. The inner mold of the knob cover is provided with a digital punch And a knob cover mold, the knob cover inner layer mold is provided with an inner layer mold injection runner, the knob cover inner layer mold is used for injection molding the inner layer 1 of the knob cover; the knob cover outer layer mold is The upper half of the inner mold of the knob cover is suitable, and the corresponding position of the digital punch on the outer mold of the knob cover is provided with corresponding hollow parts; the outer mold of the knob cover is provided with an outer mold The glue runner, the outer layer mold of the knob cover is used for injection molding the outer layer 2 on the inner layer 1 of the knob cover.

[0027] The operation steps of the injection molding process in th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap