Attachment apparatus and attachment method

A bonding device and display device technology, applied in lamination devices, chemical instruments and methods, optics, etc., to achieve the effects of cost saving, uniform bonding thickness, and flow suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention (hereinafter referred to as embodiments) will be specifically described with reference to the drawings.

[0043] [A. Structure]

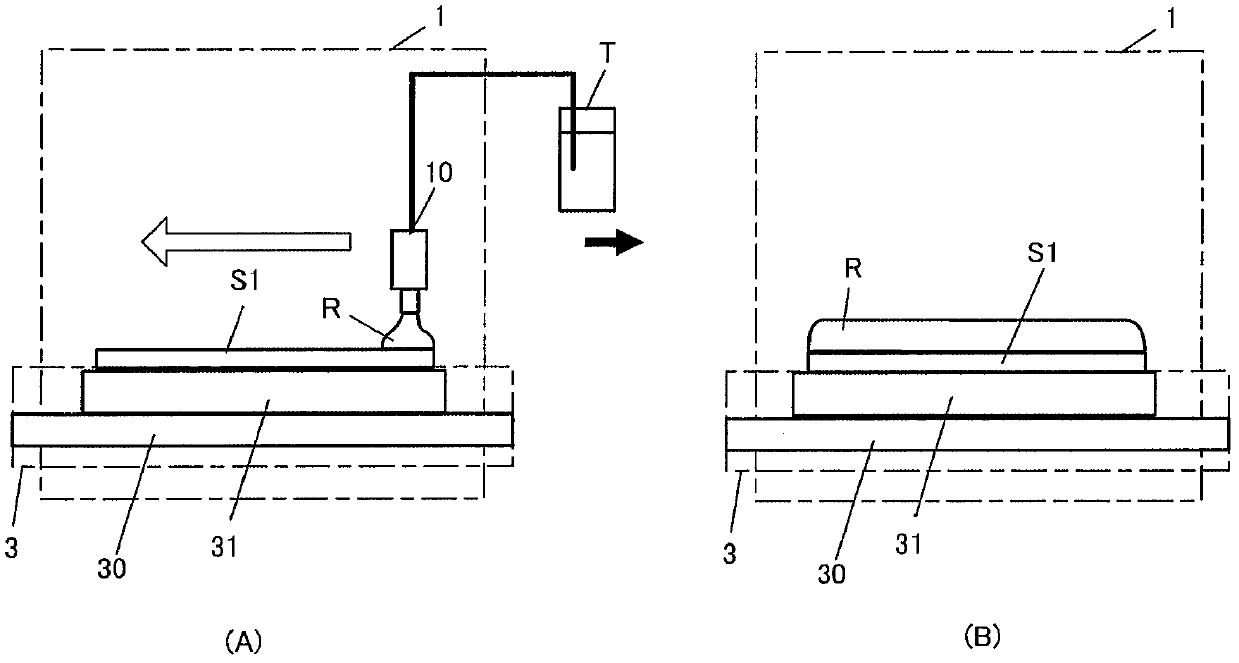

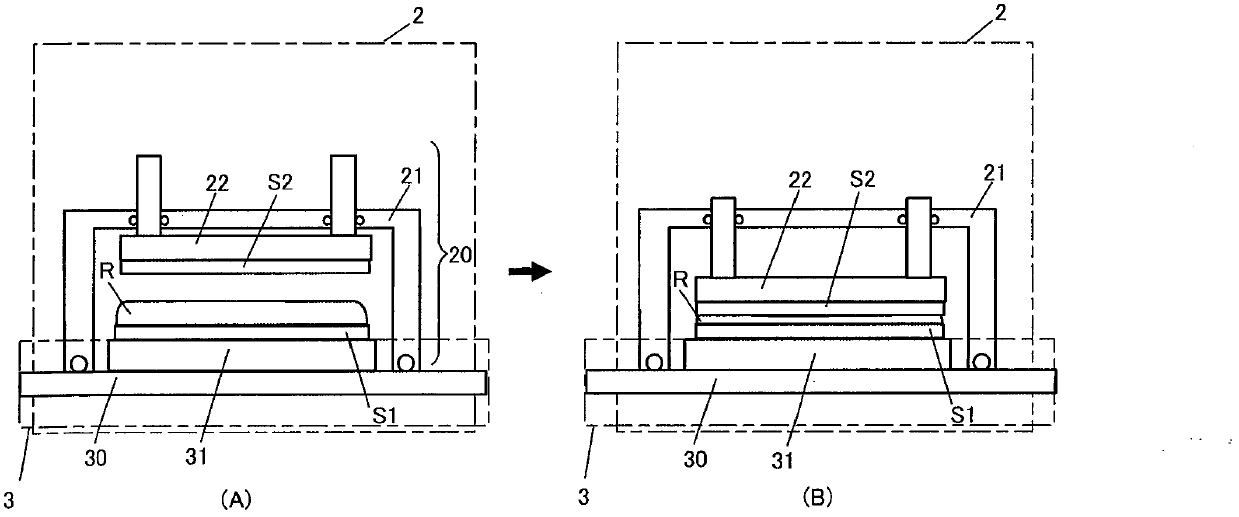

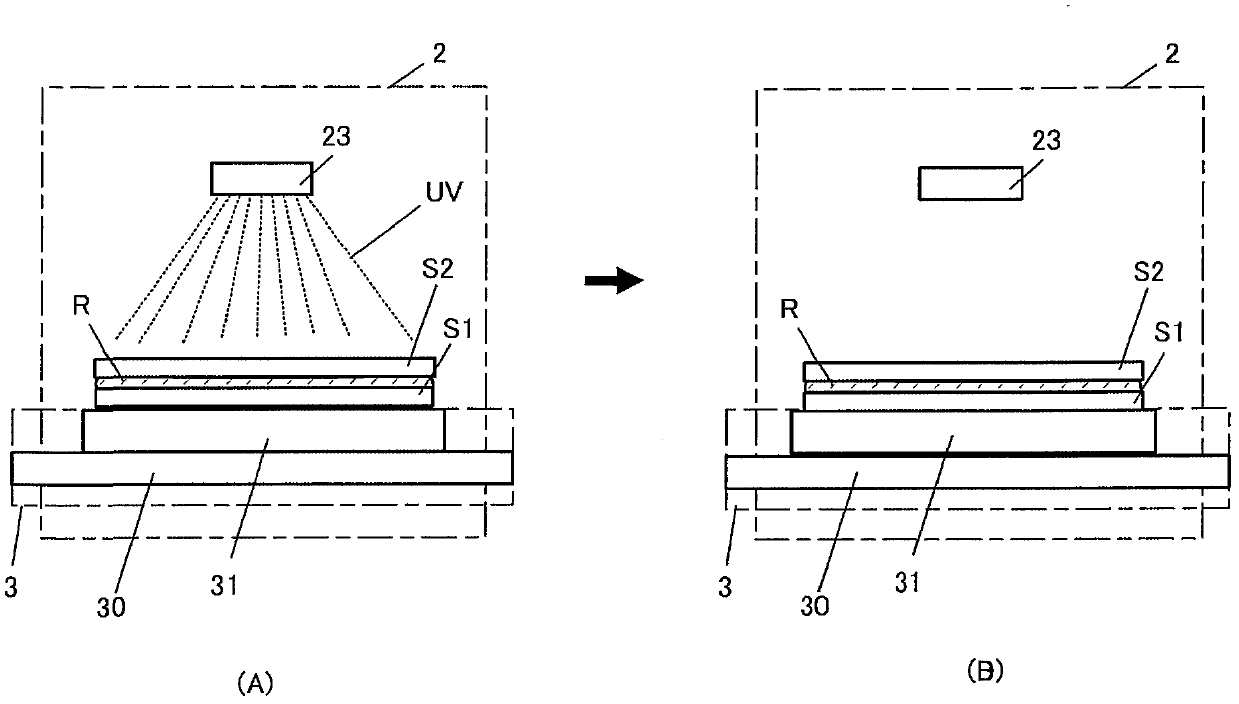

[0044] First, the structure of the adhesive supply device (hereinafter referred to as the present device) of the present embodiment will be described. Such as Figure 1~3 As shown, this device has an adhesive supply unit 1, a bonding unit 2, and the like. The workpiece S1 to be bonded is provided so as to be able to move between the adhesive supply part 1 and the bonding part 2 via the conveyance part 3 .

[0045] As the adhesive used in this embodiment, for example, an ultraviolet (UV) curable resin can be considered. Such as figure 1 As shown, the adhesive supply unit 1 has a supply unit 10 and the like. The supply part 10 is equipped with the dispenser (dispenser) which drips the adhesive agent R accommodated in the tank T on the work S1 via piping, for example. The dispenser is configured to be m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com