MEMS device and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

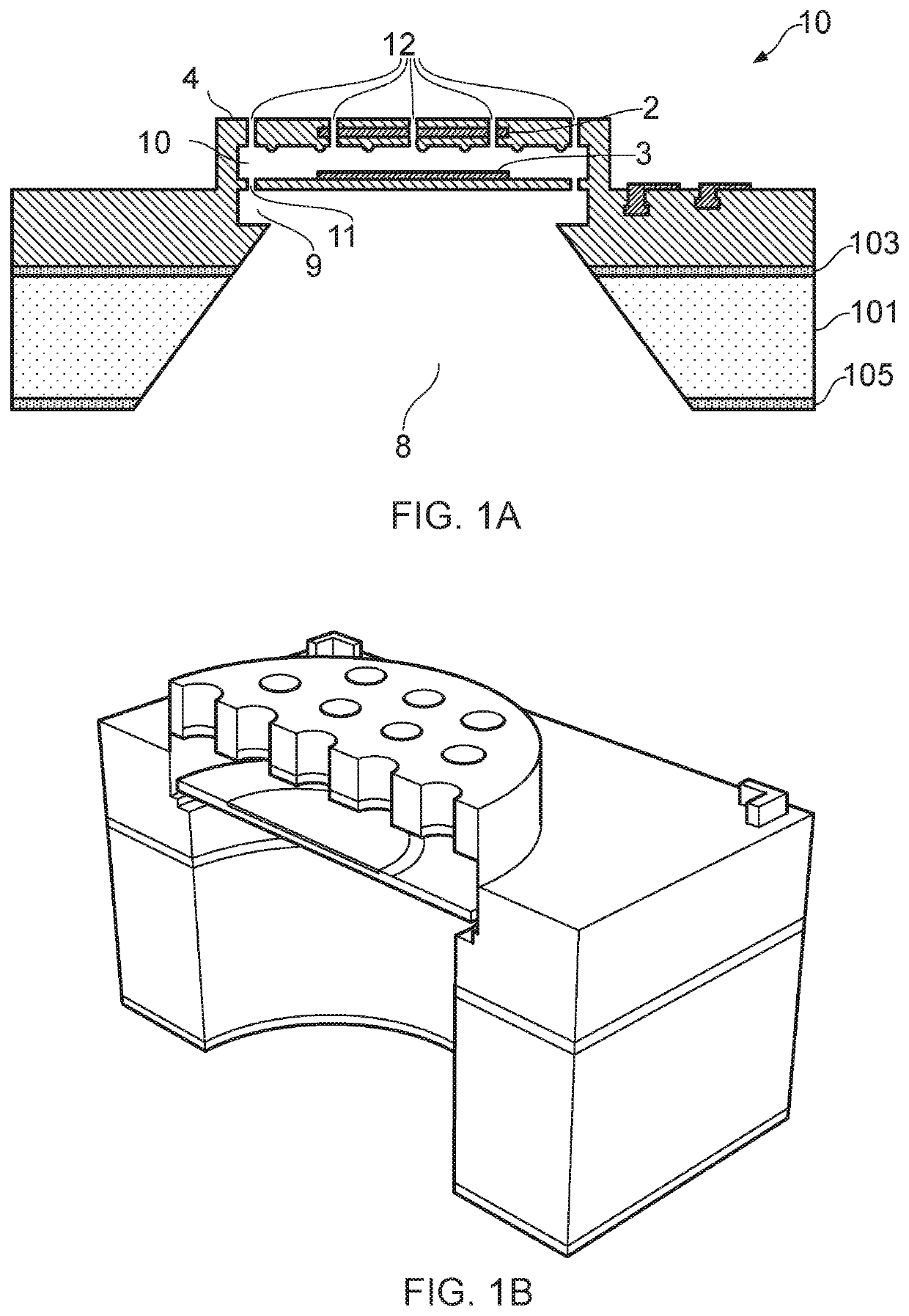

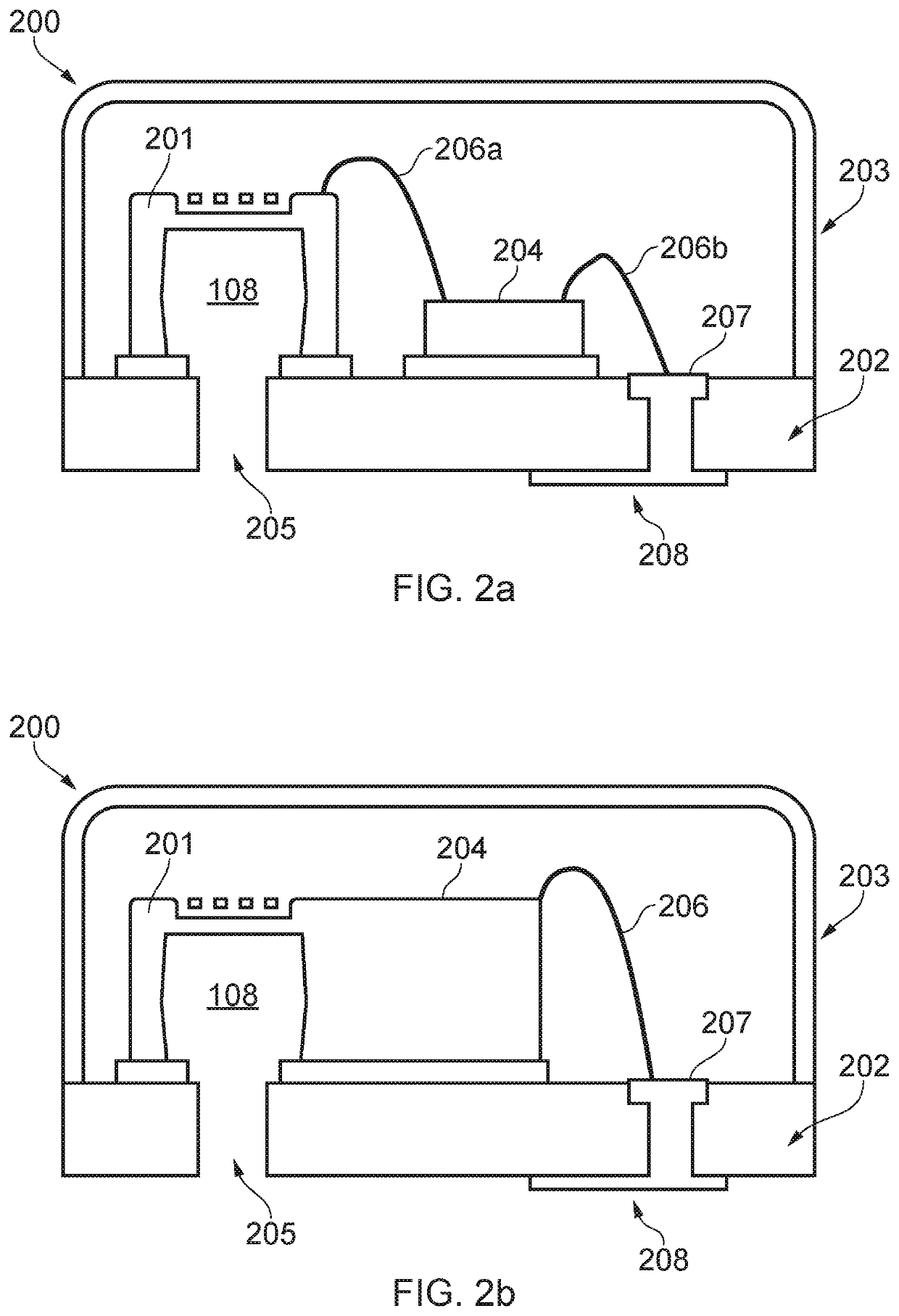

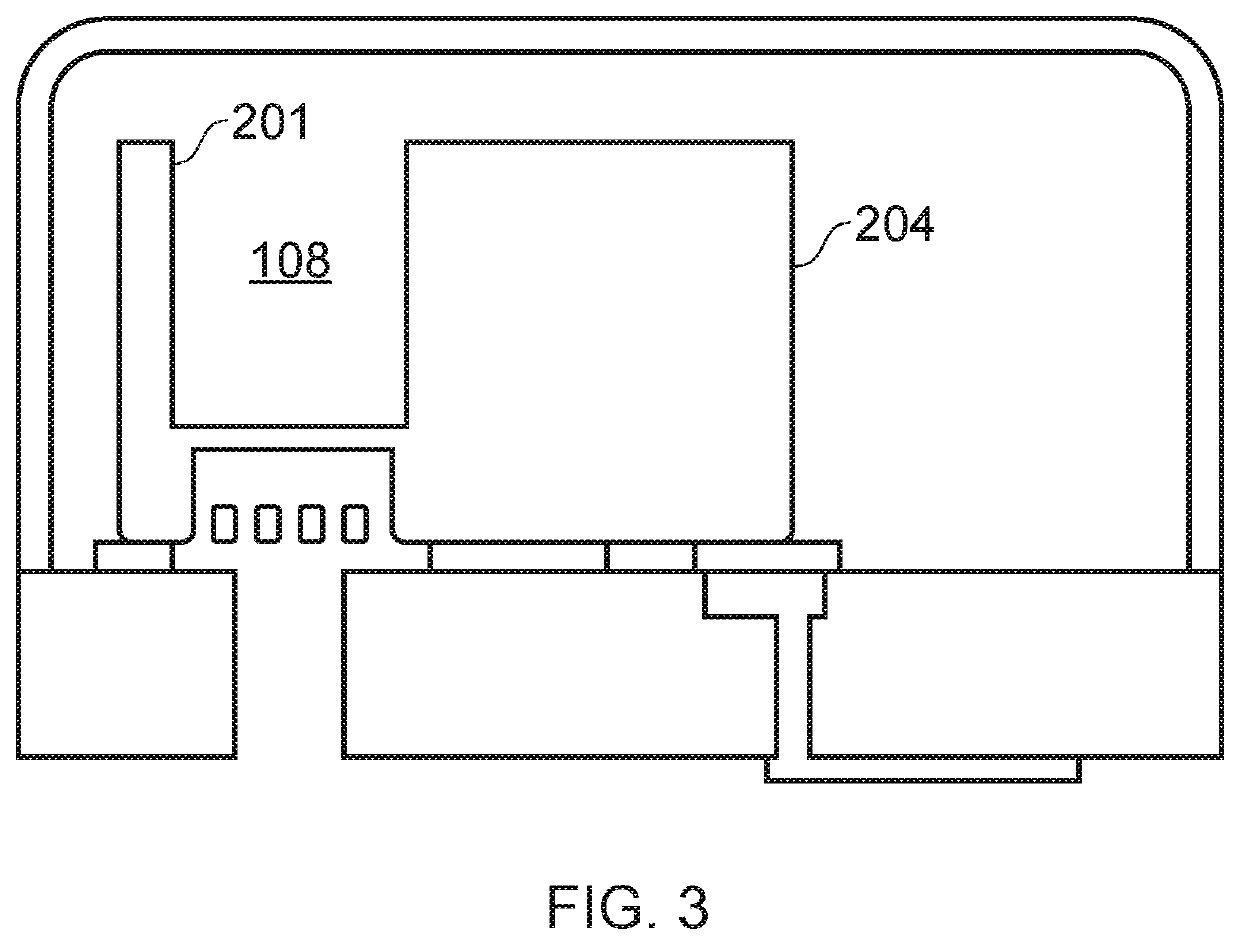

[0020]According to an example embodiment of a first aspect there is provided a MEMS device comprising a MEMS transducer, wherein the MEMS transducer comprises: a substrate having a cavity which forms a cavity opening in a upper surface of the substrate; a flexible membrane supported so as to overlie the cavity, wherein a top surface of the MEMs device comprises a barrier region, the barrier region being at least partially provided laterally outside a region which overlies the cavity opening in the upper surface of the substrate.

[0021]The barrier region may comprise one or more discontinuities in the surface of the MEMS device. Advantageously, the discontinuities serve to alter the epoxy wettability of the top surface of the MEMS device in the barrier region. Thus it is possible to define (die attach) wettable and non-wettable regions on the top surface of the MEMS device. Specifically, by providing one or more surface features or discontinuities it is possible to define epoxy non-we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Wettability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com