Preparation method of special plasticizer for plastic casing of power distribution equipment

A technology for plastic casings and power distribution equipment, applied in the chemical industry, can solve the problems of complex operation, high cost, and difficulty in popularizing and applying common products, and achieve the effect of high technical content, good quality, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

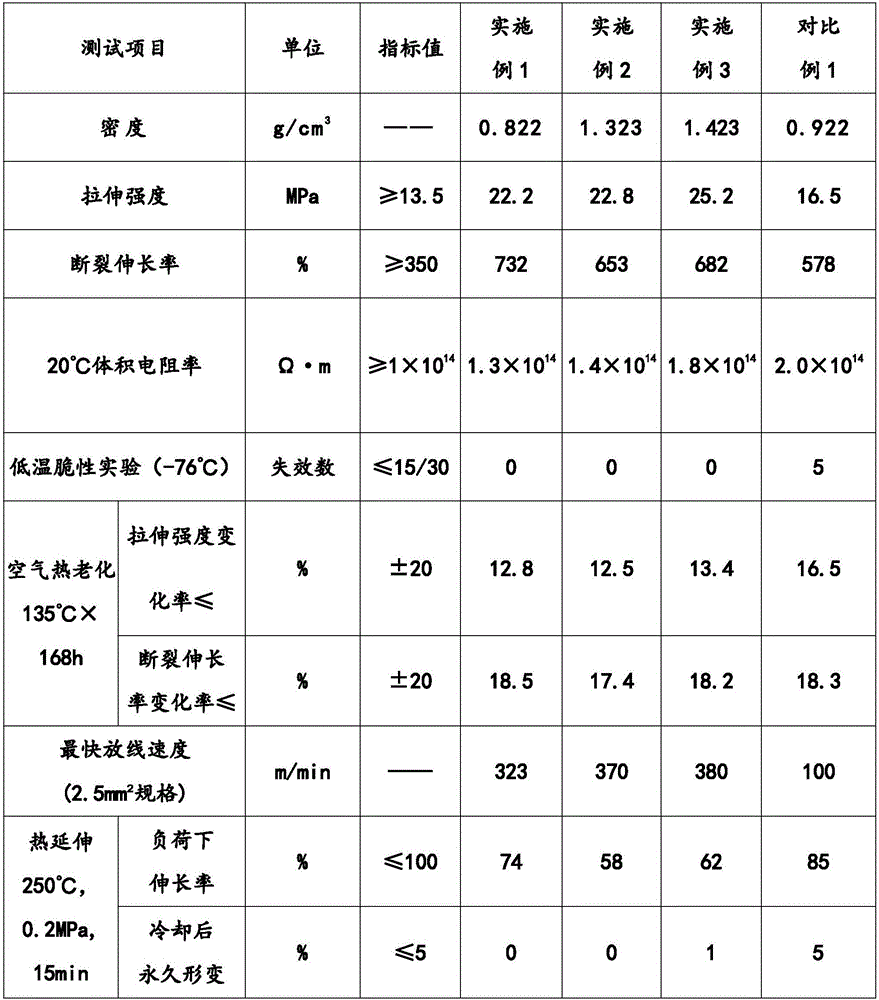

Examples

Embodiment 1

[0020] A method for preparing a special plasticizer for plastic shells of power distribution equipment, the specific method steps are as follows:

[0021] (1) add waste oil and formic acid that reclaims back in reactor, the feed intake of formic acid is 1% of waste oil gross weight, after feeding finishes, add ethanol from head tank, the feed intake of ethanol and waste oil feed amount The molar ratio is 1.2:0.5, turn on the mixer and mix evenly;

[0022] (2) Open the steam valve, heat up the reaction kettle, control the reaction temperature at 80°C, keep it for 80 minutes, then open the reaction kettle to stir, continue stirring for 40 minutes, and terminate the reaction;

[0023] (3) After the reaction is over, the reactants are left to stand for stratification, and the upper oil separation is taken, and the upper oil separation is transferred to the fractionation still, the temperature of the still is raised, and the temperature is controlled at 50 ° C, and the unreacted is...

Embodiment 2

[0028] A method for preparing a special plasticizer for plastic shells of power distribution equipment, the specific method steps are as follows:

[0029] (1) add waste oil and formic acid that reclaims back in reactor, the feeding amount of formic acid is 1~5% of the waste oil gross weight, after feeding finishes, add ethanol from the head tank, the feeding amount of ethanol is the same as the waste oil feeding amount The molar ratio of the amount is 1.2:0.8, and the mixer is turned on to mix evenly;

[0030] (2) Open the steam valve, heat up the reaction kettle, control the reaction temperature at 120° C., keep it for 80 minutes, then open the reaction kettle to stir, continue stirring for 50 minutes, and terminate the reaction;

[0031] (3) After the reaction is over, the reactants are left to stand for stratification, and the upper oil separation is taken, and the upper oil separation is transferred to the fractionation still, and the temperature of the still is raised, an...

Embodiment 3

[0036] A method for preparing a special plasticizer for plastic shells of power distribution equipment, the specific method steps are as follows:

[0037] (1) add waste oil and formic acid that reclaim in reactor, the feed intake of formic acid is 3% of waste oil gross weight, after feeding finishes, add ethanol from head tank, the feed intake of ethanol and waste oil feed intake The molar ratio is 1.2:0.65, turn on the mixer and mix evenly;

[0038] (2) Open the steam valve, heat up the reaction kettle, control the reaction temperature at 100° C., keep it for 80 minutes, then open the reaction kettle to stir, continue stirring for 45 minutes, and terminate the reaction;

[0039] (3) After the reaction is over, the reactant is left to stand for stratification, the upper layer oil separation is taken, the upper layer oil separation is transferred to the fractionation still, the temperature of the still is raised, the temperature is controlled at 55 ° C, and the unreacted is rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com