Method for recycling waste polyester/cotton blended fabric

A cotton blending and polyester technology, applied in the preparation of carboxylate/lactone, carbon preparation/purification, organic chemistry, etc., can solve the problems of narrow application range, environmental pollution, complex chemical treatment process, etc., and achieve recycling Completely processed, process-advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

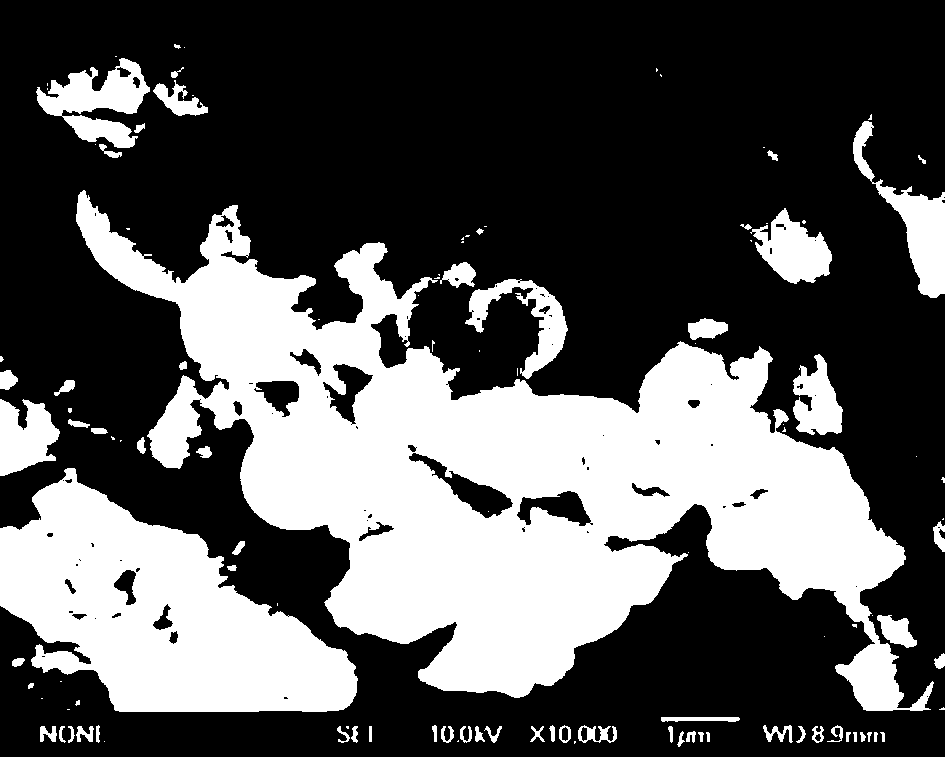

[0032] Weigh 10g of waste polyester / cotton blended fabrics after cleaning and disinfection, cut into 1×1mm size waste polyester / cotton blended fabric fragments, add to a beaker filled with 500ml of deionized water, and disperse for 2 hours with a power of 90W and a frequency of 40kHz to obtain a dispersion , together into a high-pressure reactor with a volume of 1000ml, sealed, heated to 250°C at a heating rate of 5°C / min, and kept at an autogenous pressure of 3.2MPa for 240min to carry out the degradation reaction of cotton fibers and polyester fibers.

[0033] Continue to raise the temperature to 300 ° C, and keep it warm for 480 minutes under the autogenous pressure of 7.2 MPa to carry out the carbonization reaction of the cotton fiber degradation products.

[0034] Turn off the electric heater, and after the temperature in the reaction kettle is naturally cooled to room temperature, open the reaction kettle, take out the reaction product, and centrifuge the obtained product...

Embodiment 2

[0043] Weigh 12g of waste polyester / cotton blended fabric after cleaning, disinfection and washing, and cut it into 1.2×1.2mm, add it to a beaker filled with 600ml deionized water, and disperse it with ultrasonic waves with a power of 100W and a frequency of 40kHz for 2h to obtain a dispersion , and then put them together in a high-pressure reactor with a volume of 1000ml and seal it, raise the temperature to 100°C, continue to heat up to 240°C under stirring, and keep warm for 250min under the autogenous pressure of 3MPa to carry out the degradation reaction of cotton fiber and polyester fiber.

[0044] Continue to raise the temperature to 320°C, and keep it warm for 500min under the autogenous pressure of 8MPa to carry out the carbonization reaction of the cotton fiber degradation products.

[0045] Turn off the electric heater, and after the temperature in the reaction kettle is naturally cooled to room temperature, open the reaction kettle, take out the reaction product, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com