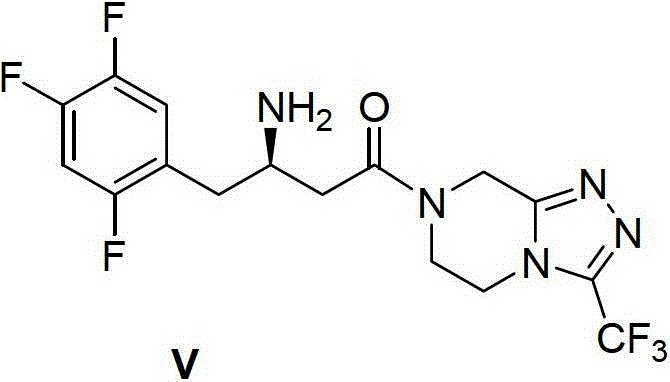

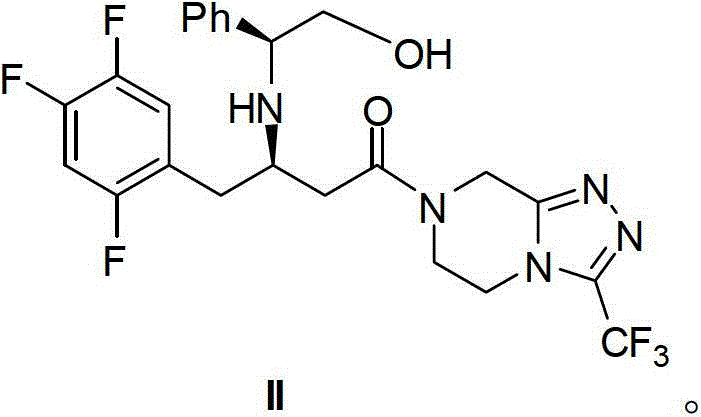

Preparation method of sitagliptin and intermediate of sitagliptin

A compound and organic acid technology, applied in the field of a method of drug sitagliptin and its intermediates, can solve the problems of limited induction ability of R-(+)-phenylethylamine, loss of isomers, etc. Strong sex-inducing ability, easy to operate, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

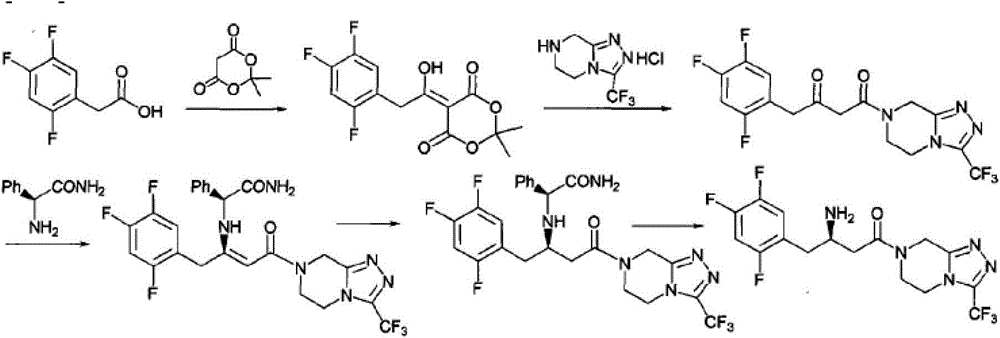

Method used

Image

Examples

preparation Embodiment 1

[0044] Dissolve 2.5 g of compound III in 12 mL of methanol, and stir to dissolve. 0.8 g of compound IV and 0.2 g of acetic acid were added to the system. After the addition is completed, the temperature is raised to 60-65° C. to react for about 8 hours, and the reaction is detected by TLC until the conversion of the raw materials is basically complete.

[0045] Heating was stopped, the temperature of the reaction system was lowered to 0-10°C, and stirring was continued for 1 hour. Filter and wash the filter cake with 12 mL of methanol. The obtained solid was dried in vacuo to obtain 2.8g of compound I with a yield of 86% and a purity of 98%. 1 H NMR (400MHz, DMSO-d 6 ):δ10.159-10.181(d,1H),7.437-7.488(m,1H),7.220-7.288(m,2H),7.187-7.208(q,2H),7.115-7.136(t,2H),5.075 -5.101(q,1H),4.977(s,1H),4.806(s,2H),4.461-4.482(t,1H),4.160-4.185(t,2H),3.934(s,2H),3.405-3.583 (m,4H).

preparation Embodiment 2

[0047] 5 g of Compound III was dissolved in 25 mL of ethanol, and stirred to dissolve. 1.6 g of compound IV and 0.4 g of acetic acid were added to the system. After the addition is completed, the temperature is raised to 60-65° C. to react for about 8 hours, and the reaction is detected by TLC until the conversion of the raw materials is basically complete.

[0048] Heating was stopped, the temperature of the reaction system was lowered to 0-10°C, and stirring was continued for 1 hour. Filter and wash the filter cake with 25 mL of ethanol. The obtained solid was dried in vacuo to obtain 5.5 g of compound I with a yield of 84% and a purity of 97%.

preparation Embodiment 3

[0050] 23 g of compound III was dissolved in 115 mL of isopropanol, and stirred to dissolve. 8.4 g of compound IV and 1.7 g of acetic acid were added to the system. After the addition is completed, the temperature is raised to 60-65° C. to react for about 8 hours, and the reaction is detected by TLC until the conversion of the raw materials is basically complete.

[0051] Heating was stopped, the temperature of the reaction system was lowered to 0-10°C, and stirring was continued for 1 hour. Filter and wash the filter cake with 12 mL of isopropanol. The obtained solid was dried in vacuo to obtain 25g of compound I with a yield of 81% and a purity of 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com