Melt polycondensation reaction method, and reactor and falling film tube used for same

A polycondensation reactor and melt polycondensation technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, thin-film liquid-gas reaction, etc. The problems of unfavorable adhesion and polycondensation process can be achieved to improve quality stability and uniformity, uniform reaction temperature and sufficient heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

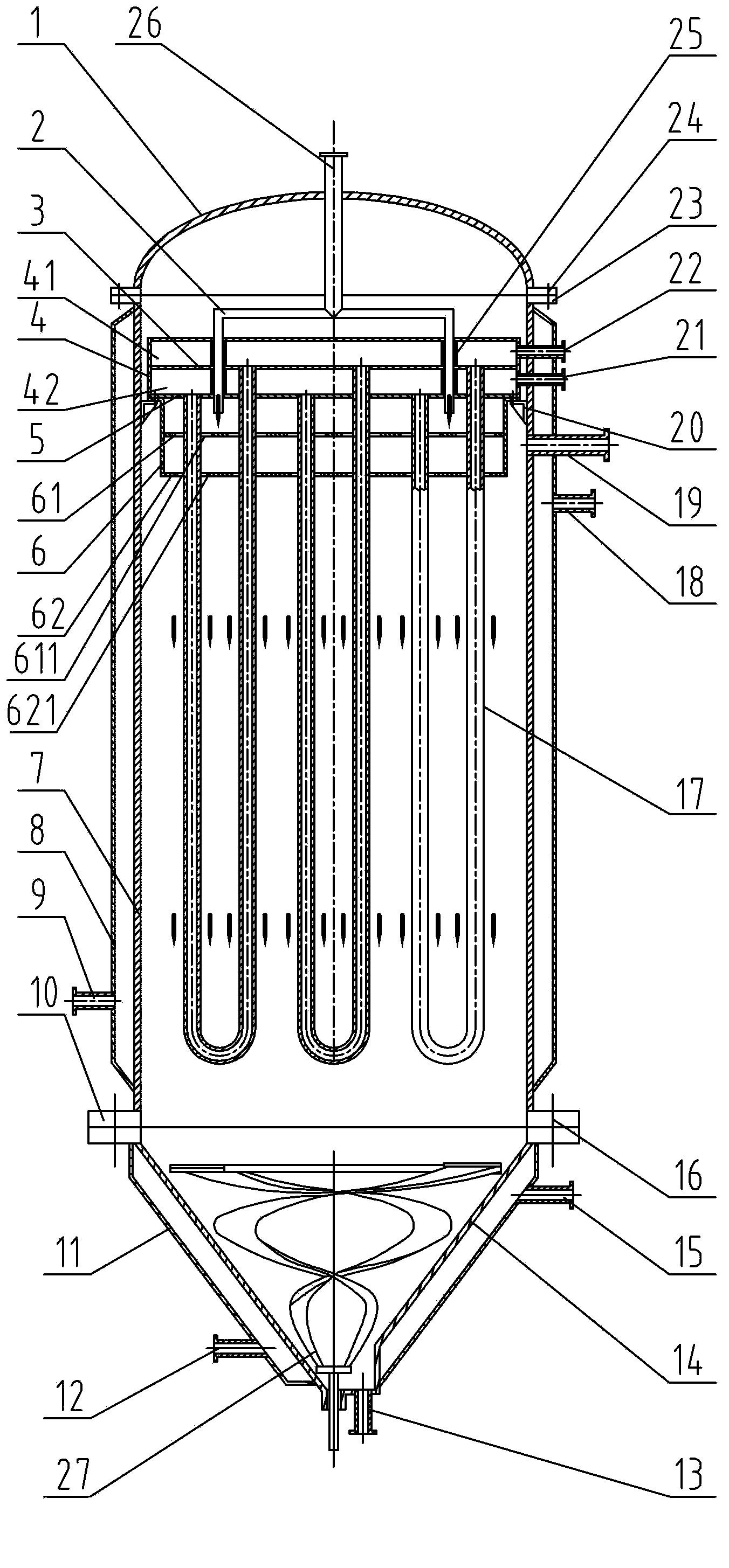

[0036] Embodiment 1, with reference to attached figure 1 .

[0037] In this embodiment, the U-shaped falling film tube is a round tube.

[0038] A kind of melting polycondensation reactor provided by the present embodiment, such as figure 1As shown, it includes: a vertical housing 7, a head 1 connected to the upper end of the vertical housing 7 and a bottom shell 14 at the lower end, the top of the head 1 is provided with a feed port 26, and the top of the vertical housing 7 is provided with Vacuum suction port 19, the bottom of the bottom shell 14 is provided with a discharge port 13, there are many vertically installed U-shaped falling film tubes 17 in the vertical shell 7, and an agitator 27 is installed below the U-shaped falling film tubes 17; The reactor has a heat transfer system, including: heat transfer medium inlet or outlet 22, upper box 41, U-shaped falling film tube 17, lower box 42, heat transfer medium outlet or inlet 21, upper box, U-shaped falling film The ...

Embodiment 2

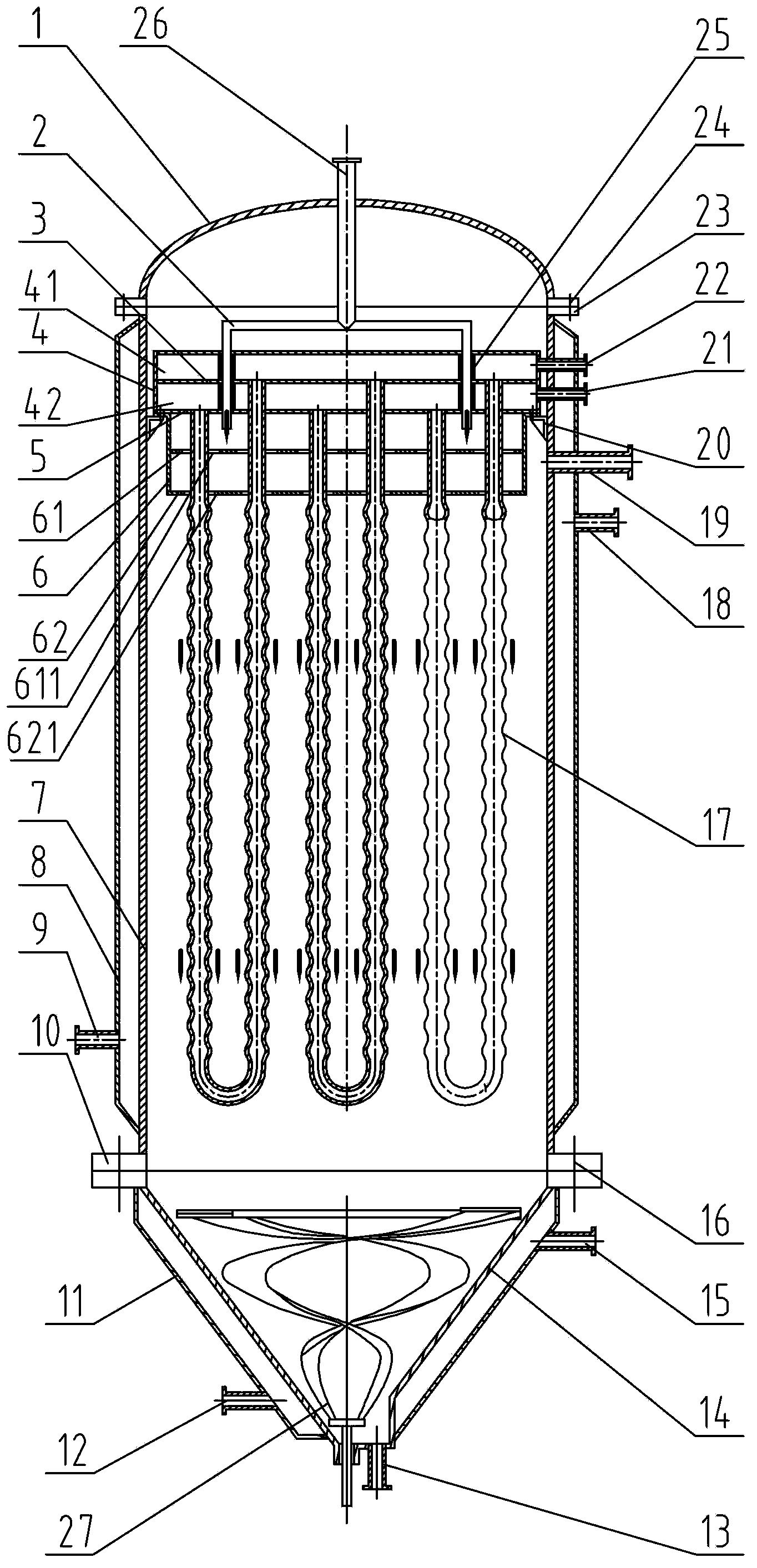

[0050] Embodiment 2, with reference to attached figure 2 , 4 , 5a, 5b, 5c, 5d.

[0051] In this embodiment, the straight part of the U-shaped falling film tube 17 is a corrugated tube or a corrugated tube.

[0052] Such as Figure 4 As shown, the corrugated tube is composed of arc sections and straight tube sections alternately, and the peak diameter D 2 and straight pipe diameter D 1 The difference and the arc segment length L 1 Ratio (D 2 -D 1 ) / L 1 =0.05~1.0.

[0053] Such as Figure 5a As shown, the bellows can be arc-shaped bellows, that is, the longitudinal tangent contour of the bellows is a continuous wave tangent to the large and small arcs.

[0054] Such as Figure 5b As shown, the bellows can be a scaling bellows, that is, the bellows is composed of expansion sections and contraction sections alternately.

[0055] Such as Figure 5c As shown, the bellows can choose the arc tangent type bellows, that is, the longitudinal tangent contour of the bellows i...

Embodiment 3

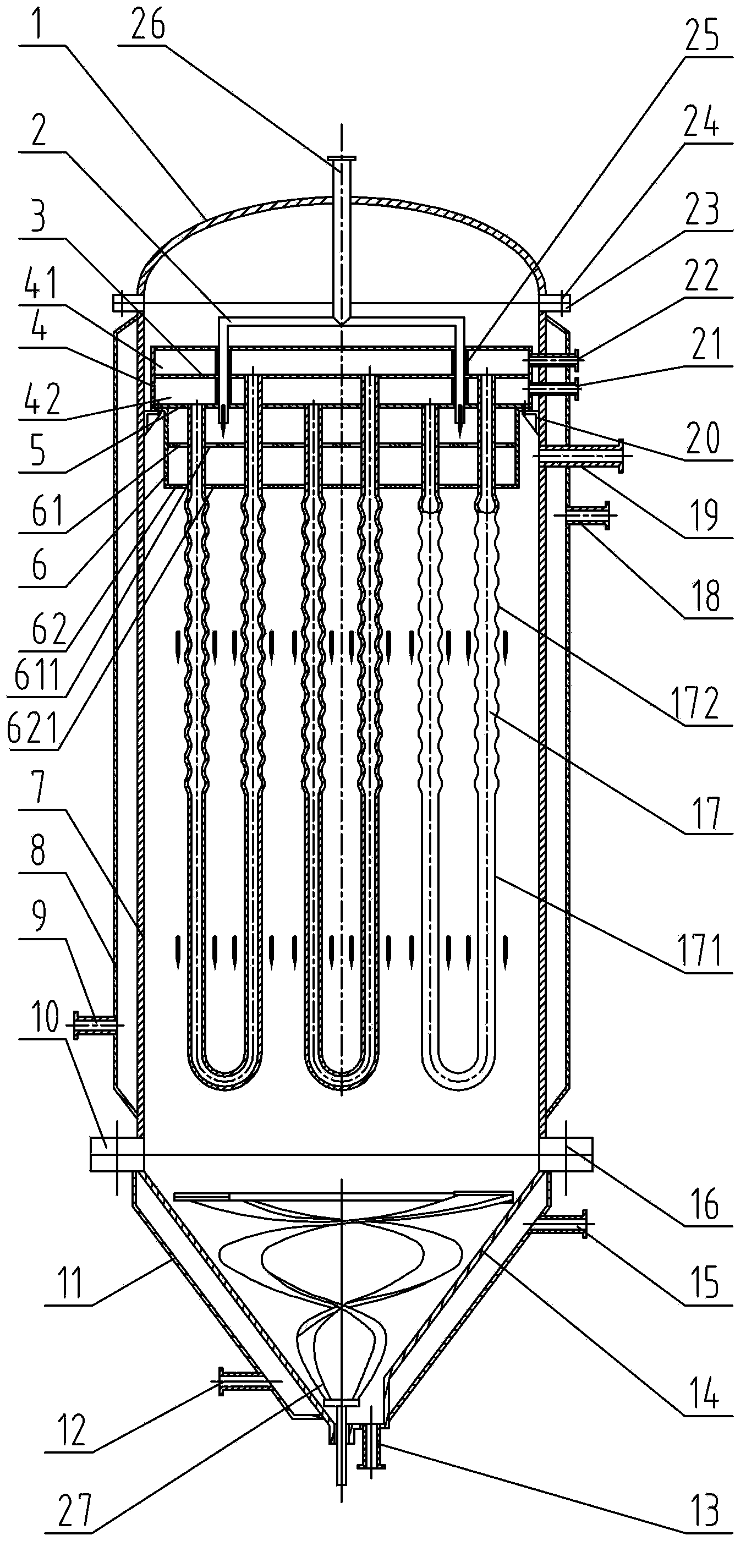

[0060] Embodiment 3, with reference to attached image 3 , 4 , 5a, 5b, 5c, 5d.

[0061] In this embodiment, the upper section of the straight part of the U-shaped falling film tube 17 is a corrugated tube or bellows 172, and the lower section is a round tube 171. The upper section and the lower section are coaxial, and the length of the upper section is determined according to the viscosity of the feed melt. If the viscosity is high, the length will be short, otherwise it will be long. The length of the lower section is determined according to the viscosity of the discharged melt. If the viscosity is high, the length will be long, otherwise it will be short; The crest diameter D of the U-shaped falling film tube 17 2 5-100mm, height 0.5-30m.

[0062] Other parts and implementation method of this embodiment are the same as embodiment 1, in image 3 , the reference numerals and figure 1 The same means the same meaning.

[0063] In this embodiment, according to the viscosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com