Melt polycondensation reaction method for preparing high-viscosity molten mass, and special reactor and falling film element used for same

A polycondensation reactor, melt polycondensation technology, applied in chemical/physical/physicochemical fixed reactors, etc., can solve the problems of unstable liquid film flow process, unfavorable polycondensation process devolatilization, insufficient melt homogenization and mixing, etc. Achieve the effects of improving instability, improving quality stability and uniformity, and improving film forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

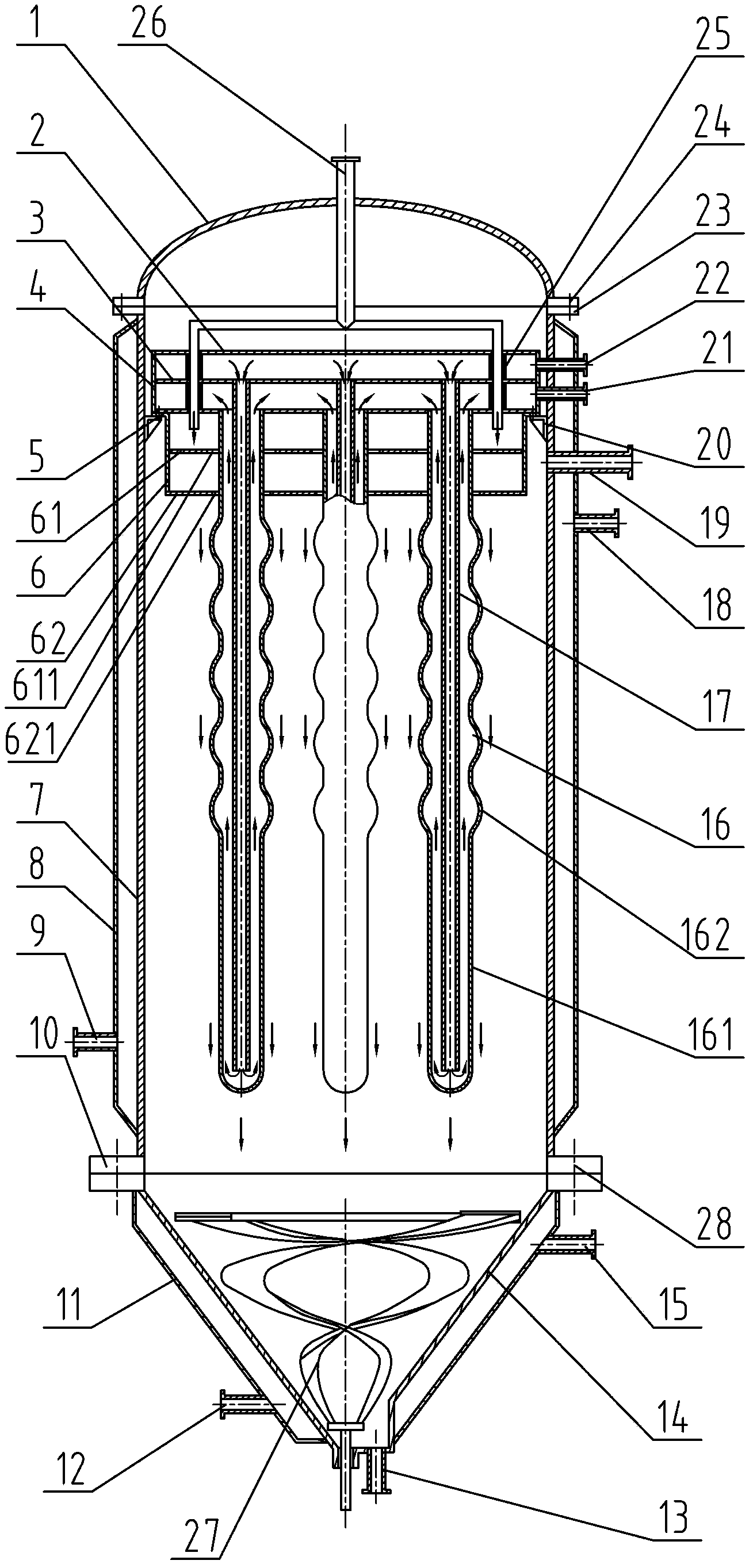

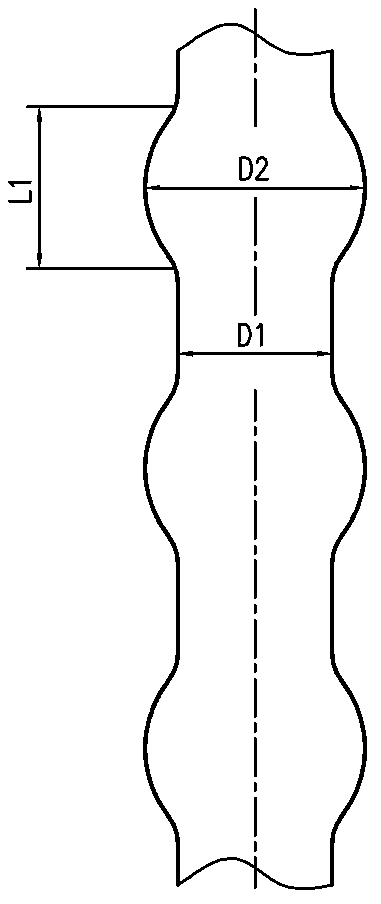

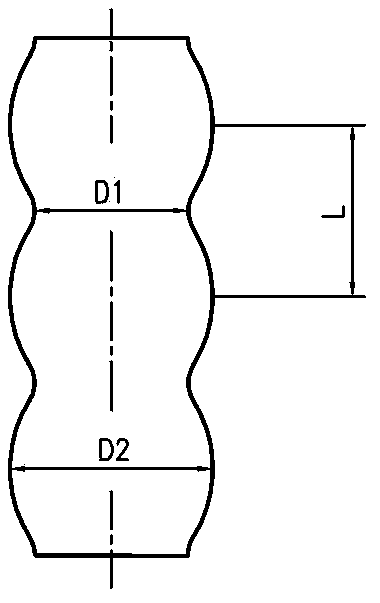

[0036] A kind of melting polycondensation reactor provided by the present invention, such as figure 1 As shown, it includes: a vertical housing 7, a head 1 connected to the upper end of the vertical housing 7 and a bottom shell 14 at the lower end, the upper part of the vertical housing 7 is provided with a vacuum port 19, and the top of the head 1 is provided with The feed port 26, the bottom of the bottom shell 14 is provided with a discharge port 13; the upper end of the vertical housing 7 is connected and installed with a cylindrical box 4 through a fastener, and the cylindrical box 4 is composed of an upper cover plate 2 and a middle partition 3 It is divided into two layers of boxes with the bottom plate 5, the upper box communicates with the heat transfer medium inlet 22, the lower box communicates with the heat transfer medium outlet 21, and a storage tray 6 is hung under the cylindrical box 4; the vertical housing 7 There are many falling film elements 16 arranged ver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com