Secondary feeding device and secondary feeding method therefor

A technology of secondary feeding and feeding, which is applied in chemical instruments and methods, self-melting liquid pulling method, crystal growth, etc. The effect of the feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0021] Explanation of terms:

[0022] Single crystal furnace: in an inert gas environment, a graphite resistance heater is used to melt the silicon material and grow a dislocation-free single crystal by the Czochralski method.

[0023] Secondary feeding: refers to the silicon material in the quartz crucible of the single crystal furnace after being filled and melted once, and then the silicon material is added to the interior once.

[0024] Single crystal side skin material: the silicon material at the edge of the single crystal rod cut during the cutting process of the single crystal rod.

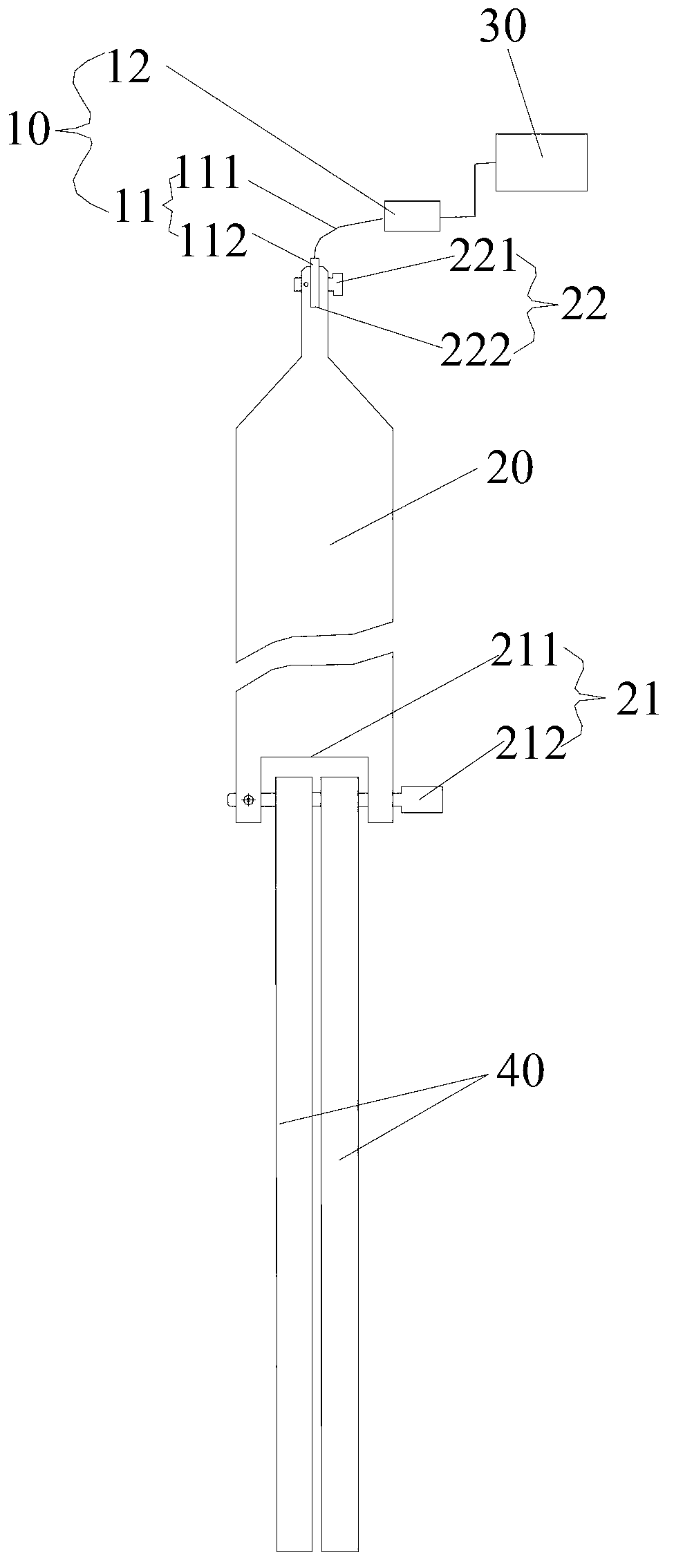

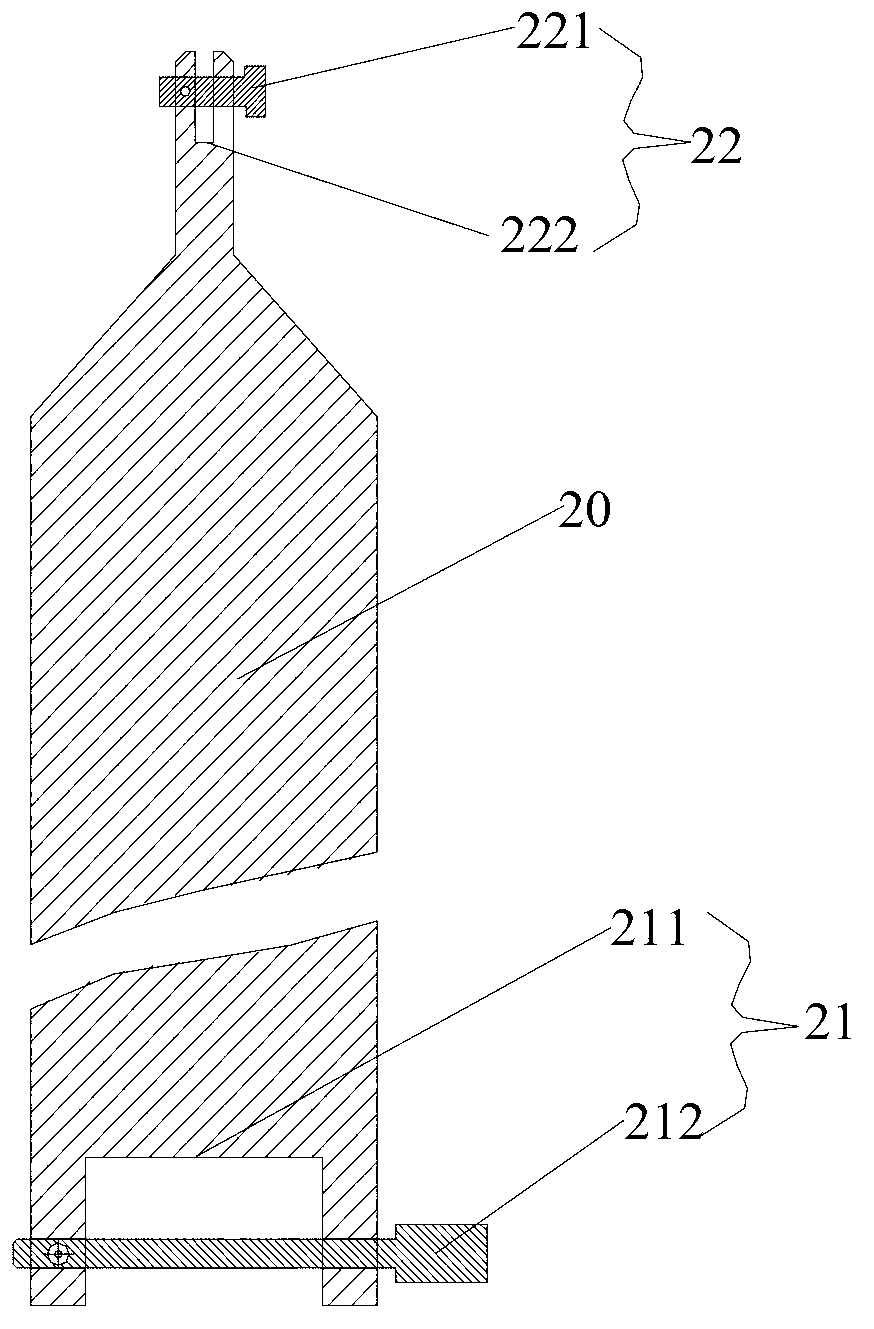

[0025] see figure 1 and figure 2 As shown, according to an embodiment of the present invention, the secondary feeding device includes a secondary feeder 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com