A pressure bearing assembly and method of use

A pressure-bearing plate and component technology, applied in the field of pressure-bearing plate components, can solve the problems of small pull-out force, weak pull-out force, small application range, etc., to achieve improved pull-out force, ingenious structure, and improved application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

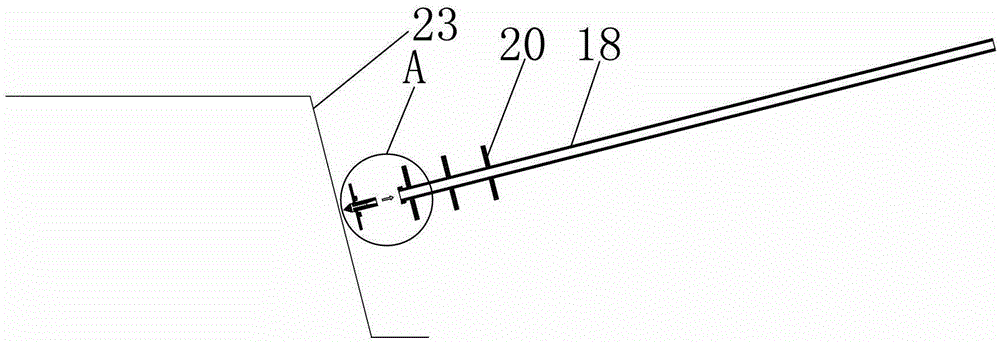

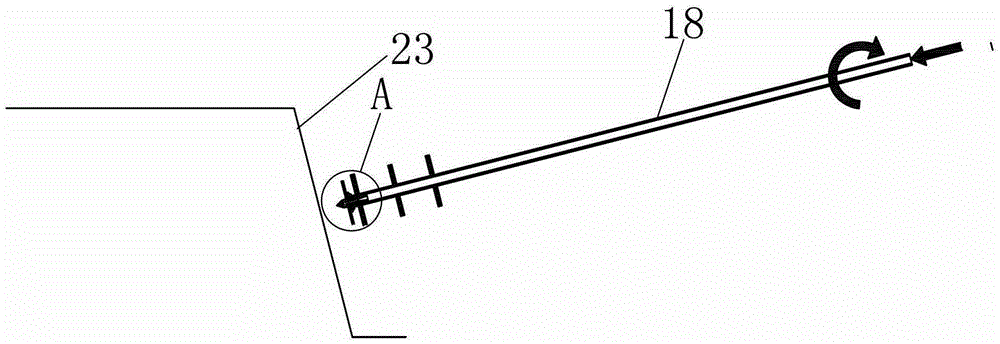

[0037] Embodiment: a kind of bearing plate type anchor pile, as Figure 8 , Figure 9 As shown, it includes a pressure bearing plate assembly 1 and steel bars 14. The pressure bearing plate assembly 1 is located deep in the formation 23. The steel bars 14 are inserted in the formation 23 and connected with the pressure bearing plate assembly 1. The formation 23 is all the layers except the bedrock. The formation, the bearing plate assembly 1 , the steel bar 14 and the cement soil 21 wrapped around the steel bar and filled with cement slurry or cement powder and stirred by the drill pipe blades are combined to form the anchor pile 22 .

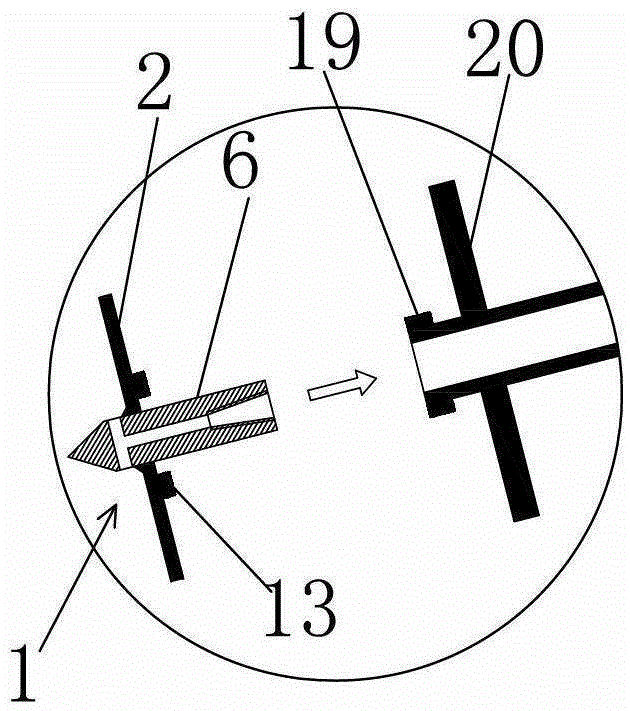

[0038] Described reinforcing bar 14 adopts reinforcing bar, as Figure 10-16As shown, the pressure bearing plate assembly 1 includes a pressure bearing plate 2, the pressure bearing plate 2 can be circular, square or other shapes, and a joint 3 is pierced at the center of the pressure bearing plate 2, and the joint 3 and the pressure bearing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com