Method and device for identifying glowing ignition in gasoline engines

A gasoline engine, hot ignition technology, applied in the direction of engine ignition, ignition safety devices, engine components, etc., can solve problems such as gasoline engine damage, and achieve the effect of reducing application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

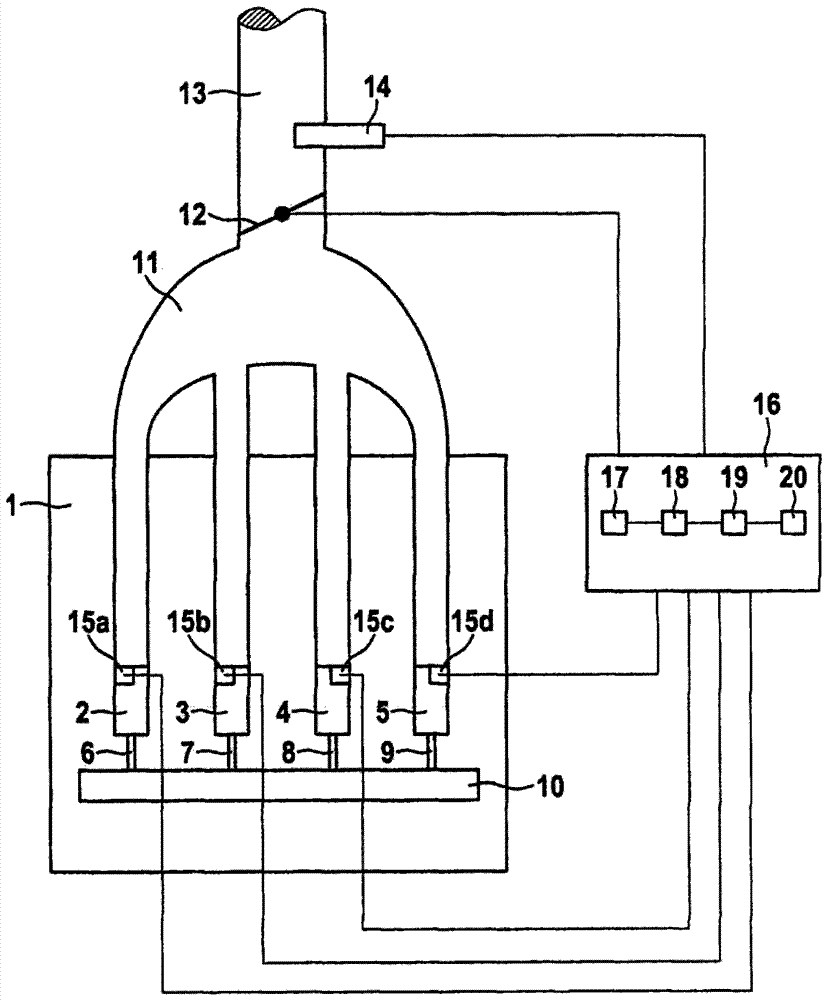

[0023] figure 1 A device for determining glowing ignition in an Otto engine 1 is shown. The gasoline engine 1, which is designed as a self-priming engine, has four cylinders 2, 3, 4, 5 in this example, the pistons of which are not shown further and move in the cylinders 2, 3, 4, 5 respectively The crankshaft 10 is connected via a connecting rod 6 , 7 , 8 , 9 and is driven due to pressure changes caused by combustion. The cylinders 2 , 3 , 4 , 5 are connected to a suction line 11 , which ends with a throttle plate 12 opposite the suction line 13 . Nozzles 14 for injecting fuel protrude into the intake manifold 13 , whereby a fuel-air mixture is formed. Alternatively, the Otto engine 1 , in particular a small engine, can be designed with direct injection, which injects fuel individually into each cylinder 2 , 3 , 4 , 5 by means of an injector. In a further variant, it is also possible to design a spray system variant comprising a straight spray device and a suction pipe spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com