Controllable torque device based on magnetorheological materials

A magnetorheological and torque technology, applied in the buffer field, can solve the problems of small damping force adjustment range, small damping force, short effective length of damping channel, etc., and achieve the effect of increasing effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

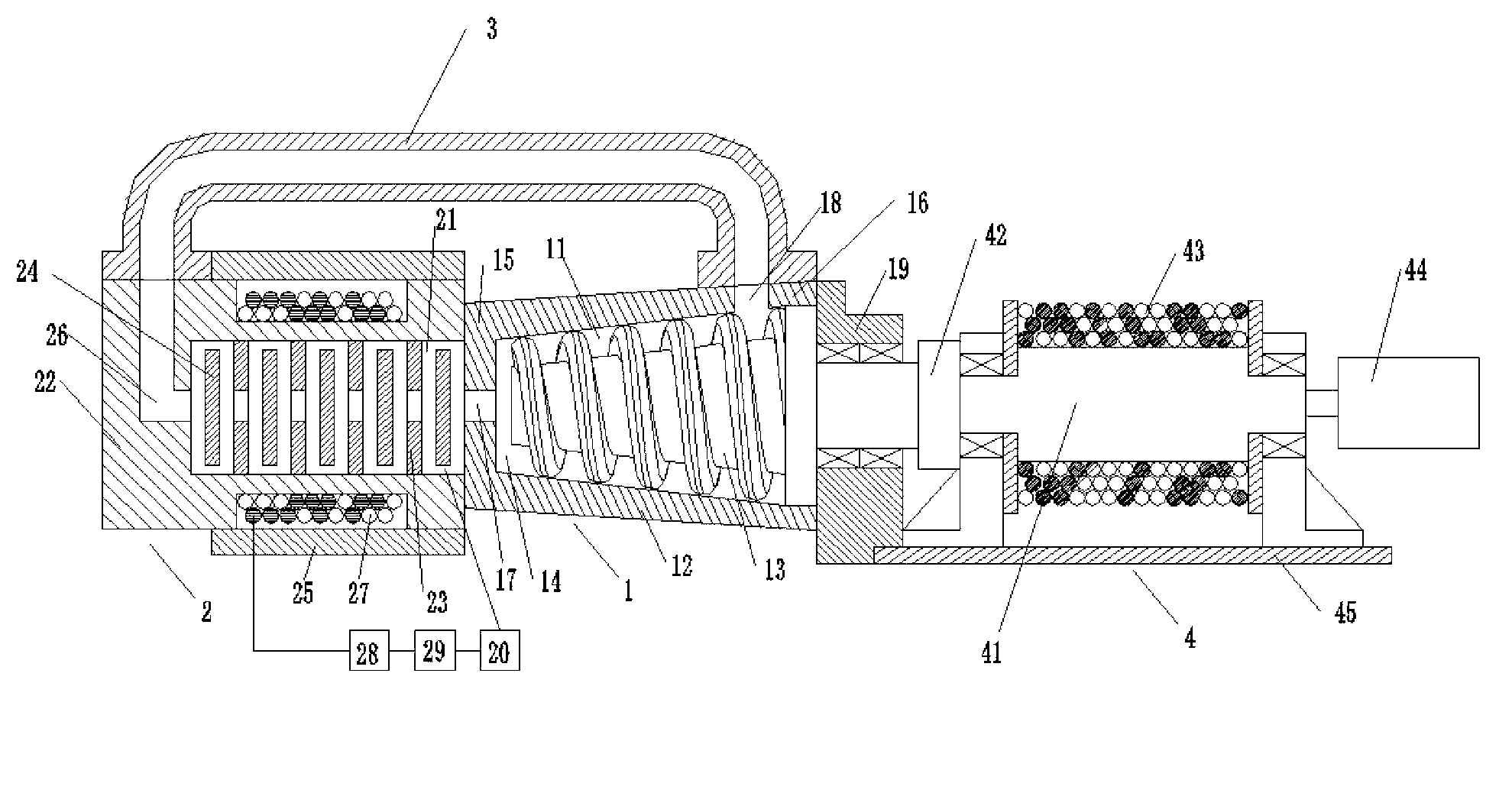

[0016] Please refer to figure 1 , is a structural schematic diagram of an embodiment of a controllable torque device based on a magnetorheological material provided by the present invention. The controllable torque device includes: a propulsion device 1 , a controllable buffer device 2 and a magnetorheological material return pipe 3 .

[0017] A spiral channel 11 is provided in the propulsion device 1 , and a multi-stage annular damping channel 21 is provided in the controllable buffer device 2 . When the propulsion device 1 works, the driving force generated by it squeezes the magnetorheological material in the spiral channel 11 into the multi-stage annular damping channel 21, and the magnetorheological material flowing into the multi-stage annular damping channel 21 is under the driving force. Under the action of the magnetorheological material, the magnetorheological material flows back into the spiral channel through the magnetorheological material return pipe 9 to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com