Low-temperature vacuum pipe connector

A low-temperature vacuum, connecting seat technology, applied in the direction of pipeline protection, protection of pipelines through thermal insulation, pipes/pipe joints/pipes, etc., can solve the problems of easy evaporation of low-temperature liquid, pressure rise, distortion, etc., to reduce heat conduction. , Increase the heat conduction path, the effect of good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

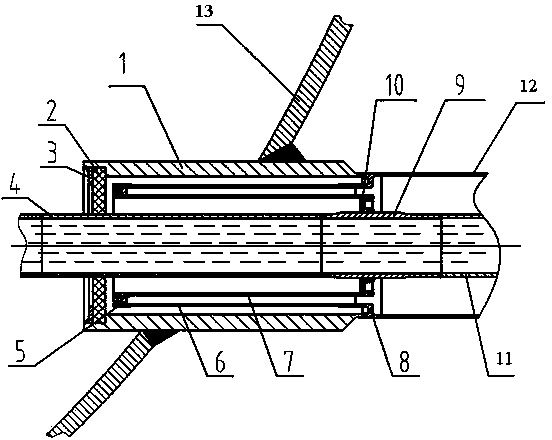

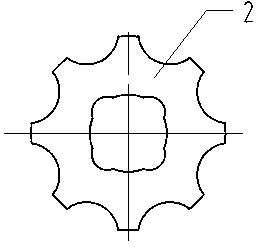

[0026] see figure 1 and figure 2 , the low-temperature vacuum pipeline connection seat of the present invention includes a liquid inlet and outlet pipe 4, an inner casing 7, a middle casing 6 and an outer casing 1, and the liquid inlet and outlet pipe 4, the inner casing 7, the middle casing 6 and the outer casing 1 are obtained from Nested from inside to outside.

[0027] The head of the liquid inlet and outlet pipe 4 is connected to the bottom of the inner tube 11 of the vacuum pipeline through the liquid inlet and outlet pipe connection joint 9, and the inside of the liquid inlet and outlet pipe 4 is a cryogenic liquid;

[0028] A connection ring III10 is provided between the head of the inner casing 7 and the liquid inlet and outlet pipe 4;

[0029] A connecting ring I5 is provided between the bottom of the inner casing 7 and the middle casing 6;

[0030] A connecting ring II 8 is provided between the head of the middle casing 6 and the outer casing 1;

[0031] The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com